Sunswell PET Bottled Still Water Blowing Filling Capping Combiblock

combi soft drinking Production Line

Description:

The Sunswell Blowing Filling Capping Combiblock machine is mainly

used for the water filling, juice filling,soft drinking filling,

with optional capacity from 2000 to 45,000b/h by PET bottle for

500ml/1000ml. The machine design is shorten the time for the drink

material contact with outside, Increased the sanitation condition

and throughout and economy benefit.

Applications:

Blowing filling capping combibloc is suitable for PET bottle

packaging of pure water, carbonated beverages, juice, tea, liquid

milk, liquid condiments and daily chemicals, etc.Compared with

traditional filling machinery, the blow-and-spin machine is

distinguished by:

- Stable infrared heating system and independent heat balance

adjustment

- The device makes the preforms have the same temperature when

heated, and the process has good

- Good consistency and stability to further improve the yield.

- Specially designed secondary air blowing system for real-time

monitoring of each mode

- The pressure change curve during the molding process of the cavity

bottle is the process

- Adjustment provides timely and accurate real-time parameters, which

greatly facilitates operation

- Workers adjust process parameters while ensuring bottle

formability.The amount is stable.

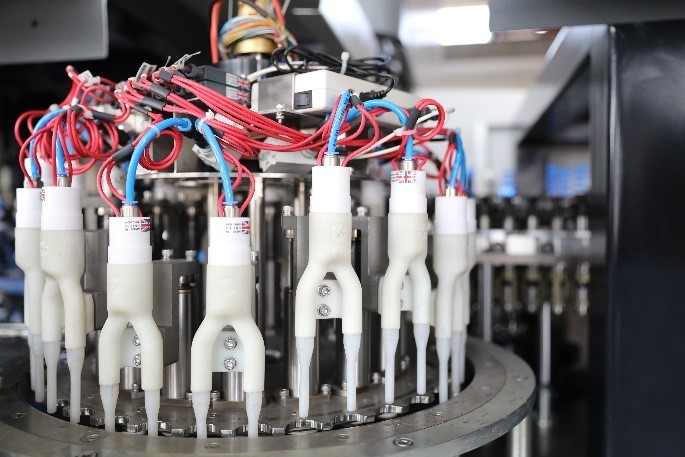

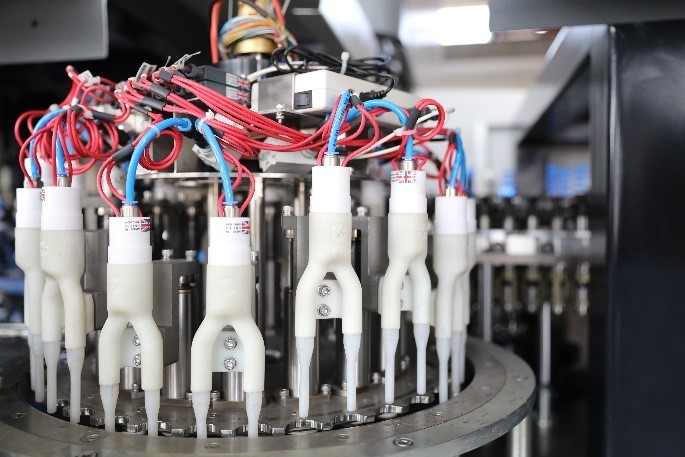

- High-speed, high-precision diaphragm filling valve: with

independent liquid

- The return air passage of the cylinder is replaced in the PET

bottle during the filling process. Air does not enter the tank to

avoid secondary pollution;

- There is a cleaning cup that enables online CIP cleaning

Product Range:

Production capacity from 12,000 BPH to 54,000 BPH.

Rotary Blow Molding Machine

1.Horizontal heating chain drive system

- Use high-strength brass processing to extend the service life

- Large caliber cooling mouth, to ensure that the preform neck not

heated, with effective protection of preform thread

2.Efficient energy-saving preform heating system

- Patented blowing nozzle unit for stable preform

- Positioning first, sealing after, to ensure that the preform

vertical blowing, more stable.

- To avoid broken bottle blocking machine phenomenon.

3.Fast mold changing unit (6-screw design)

- 6-screw mold change design

- 6-8min for each mold changing

4.H-type steel frame, reducing vibration, more stable

- Driving platen and the host frame as a whole processing, more

accurate to feed preforms. Ensure without vibration at 2000BPH each

cavity.

- H-type steel welding, high-speed rotation more stable.

5.High accurate filtration system and High pressure air recycling

system

- High-pressure air recovery system can save 30% of air, in addition,

the extra gas leads to other machines.

- High-pressure filtration system accuracy of 0.001ppmw, greatly

extend the service life of pneumatic components.

Integrated brake system with slewing ring,

more reliable and stable.

6.Reliable electrical control

- Through the teleservice remote monitoring system, real-time

recording of any operation of the field device or shutdown

information, through the analysis of software real-time analysis of

equipment operating status.

7.Air conditioning and Anti-condensation System on electrical

cabinet

8.Ion air blowing

- Ion gas blowing for removing dust on preform

- Positive and negative ion generator neutralize static electricity

on surface of preform

- Blow clean compressed air onto the surface of the preform

- Vacuum dust suction

Gravity Filling Machine

- Filling valves and tank are made of stainless steel SUS304.

- Large flat bearing with teeth, stable and reliable performance.

- Gravity filling.

- Ring shape tank with float ball level control.

- High speed and high accuracy filling valve with 200ml/s flowing

speed

- Filling valve equips dummy cup and can do CIP circularly.

- With rotary spray ball in tank to ensure cleaning effect.

- Lift by pneumatic cylinders.

Capping Machine

- Magnetic constant torque capping head ensures stability and

controls defective rate of capping less than 0.2%.

- Cap dropping rail equips a group of photoelectrical switch for

reverse cap detecting. When lack of cap, machine will be stopped

automatically.

- Bottle infeed detecting switch works with the pneumatic cylinder on

cap starwheel to avoid feeding cap on no-bottle condition.

| NO. | Model | Capacity(based on 500ml) | Remark |

| 1 | 8-32-8 | 15,000bph | |

| 2 | 10-40-10 | 18,000bph | |

| 3 | 12-40-15 | 22,000bph | |

| 4 | 14-40-15 | 24,000bph | |

| 5 | 16-50-18 | 30,000bph | |

You can click here to see more!