Xinxiang jinrui machinery factory |

|

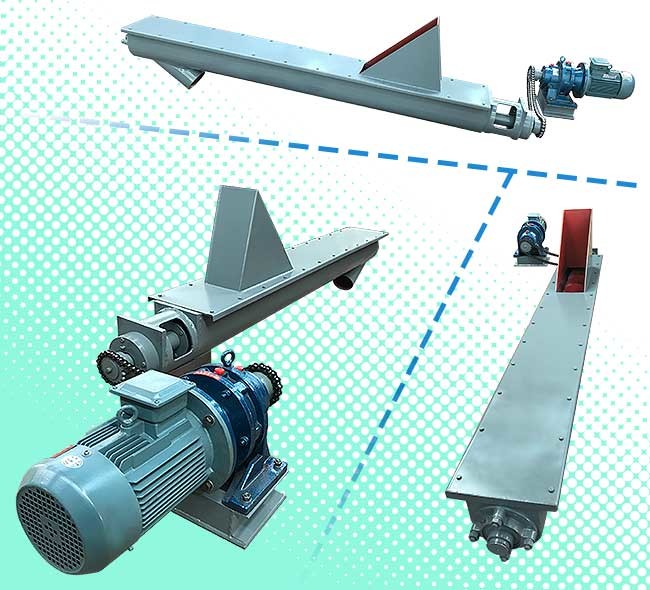

Screw conveyor is a kind of machinery that uses motor to drive screw rotation and push materials to achieve the purpose of conveying. It can be transported horizontally, obliquely or vertically. It has the advantages of simple structure, small cross-sectional area, good sealing, convenient operation, easy maintenance and closed transportation. Screw conveyor can be divided into shaft screw conveyor and shaftless screw conveyor in conveying form, and U-type screw conveyor and tubular screw conveyor in appearance. The shaft screw conveyor is suitable for cohesionless dry powder materials and small particle materials (such as cement, fly ash, lime, grain, etc.), while the shaftless screw conveyor is suitable for viscous and easy winding materials. (for example: sludge, biomass, garbage, etc.) the working principle of the screw conveyor is that the rotating spiral blade moves the material and carries out the screw conveyor conveying. The force that makes the material not rotate with the screw conveyor blade is the material weight and the friction resistance of the screw conveyor shell to the material. For spiral blades welded on the rotating shaft of screw conveyor, the surface types of blades include solid surface, belt surface, blade surface, etc. A thrust bearing is provided at the end of the screw shaft of the screw conveyor in the direction of material movement to give the axial reaction force to the screw along with the material. When the length of the machine is long, the middle hanging bearing should be added.

The screw conveyor is a kind of continuous conveying equipment

without flexible traction, which uses the rotating screw to move

the conveyed material along the fixed casing. It is as if the

unrotatable nut is held and translated along the screw. The force

that keeps the material from rotating with the screw is the gravity

of the material and the friction against the shell.

The advantages of the screw conveyor are: simple structure,

convenient maintenance, small size of the cross section, can enter

and leave materials at any position in the length direction, and

can use the cover of the tight closed housing to achieve a better

sealing effect.

Therefore, screw conveyor is widely used in various industrial

sectors to transport a variety of powdered, granular and small

materials, such as coal ash, cement, sand, coal, cereals and so on;

it is not easy to transport viscous caking materials which are easy

to deteriorate.

| Model | Diameter mm | Pitch mm | Speed r/min | Standard Capacity(m3/h) | Speed r/min | Standard Capacity(m3/h) | Speed r/min | Standard Capacity(m3/h) | ||||||

| φ0.45 | φ0.33 | φ0.15 | φ0.45 | φ0.33 | φ0.15 | φ0.45 | φ0.33 | φ0.15 | ||||||

| LS200 | 200 | 200 | 100 | 16.9 | 12.4 | 5.6 | 80 | 13.5 | 9.9 | 4.5 | 63 | 10.7 | 7.8 | 3.6 |

| LS315 | 315 | 315 | 80 | 52.9 | 38.8 | 17.6 | 63 | 41.6 | 30.5 | 13.9 | 50 | 33.1 | 24.2 | 11 |

| LS400 | 400 | 355 | 71 | 85.3 | 62.5 | 28.4 | 56 | 67.3 | 49.3 | 22.4 | 45 | 54.1 | 39.6 | 18 |

| LS500 | 500 | 400 | 63 | 133.2 | 97.7 | 44.4 | 50 | 105.8 | 77.6 | 35.3 | 40 | 84.6 | 62.0 | 28.2 |

| LS630 | 630 | 450 | 50 | 188.9 | 138.5 | 63.0 | 40 | 151.1 | 110.8 | 50.4 | 32 | 120.9 | 88.6 | 40.3 |

| Material to be processed: _____ | Working environment is indoor or outdoor:________ |

| Handling capacity: ________per hour | Working environment temperature: _______ ℃ |

| Bulk Density: _____t/m3 | Installation form is horizontal or inclined : ________ |

| Conveying distance: ________ | If it is inclined,what is the inclined degree_____° |

| Material size:____mm | Water content:____% |

| Material temperature: _______ ℃ | Working power supply: _____V ______HZ ______PH |