Xinxiang jinrui machinery factory |

|

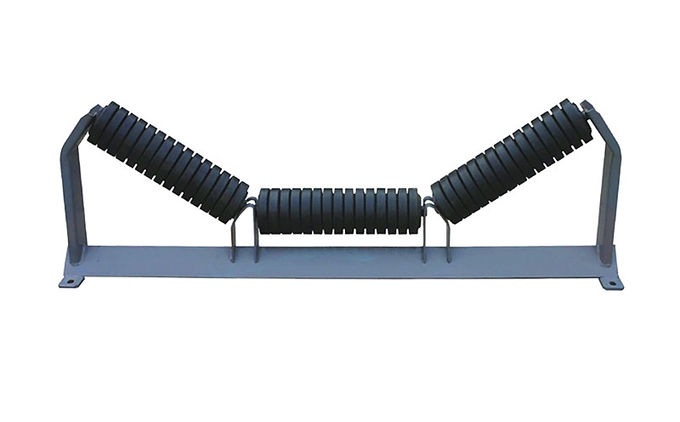

| Belt width(mm) | Roller | Bearing NO. | |

| 800 | D | L | |

| 1000 | 89 | 315 | 204,205 |

| 1200 | 108 | 380 | 204,205,305 |

| 1400 | 133 | 465 | 205,305,206,306 |

| 1600 | 133 | 530 | 205,305,206,306 |

| 1800 | 159 | 600 | 205,306,307,308,309 |

| 2000 | 159 | 670 | 207,309,308 |

| 2200 | 194 | 800 | 207,307,308,309 |

| 2400 | 194 | 900 | 206,307,308,309 |

1. It is flame-retardant, anti-static, anti-aging, and resistant to corrosion by various chemical media;

2. Super mechanical strength, can withstand repeated shocks and vibrations;

3. Extremely high wear resistance, ultra-low friction coefficient, and strong anti-adhesion ability, which can prolong the service life of the belt by 2-3 times;

4. Eliminate the worry of maintenance for life;

5. Superior sealing performance, low noise, low rotation resistance, stable operation, long service life, 2-3 times that of traditional rollers;

6. Wide temperature adaptability (can work between -40℃-80℃ for a long time);

Main function and scope of application

The role of the roller is to support the weight of the conveyor belt and the material. The operation of the roller must be flexible and reliable. Reducing the friction between the conveyor belt and the idler roller plays a key role in the life of the conveyor belt, which accounts for more than 25% of the total cost of the conveyor. Although the roller is a small part in the belt conveyor and the structure is not complicated, it is not easy to make a high-quality roller.

4.3, All of package are wrapped by 0.5mm steel belt to further strengthen.