Qingdao Leno Industry Co.,Ltd |

|

Verified Suppliers

|

|

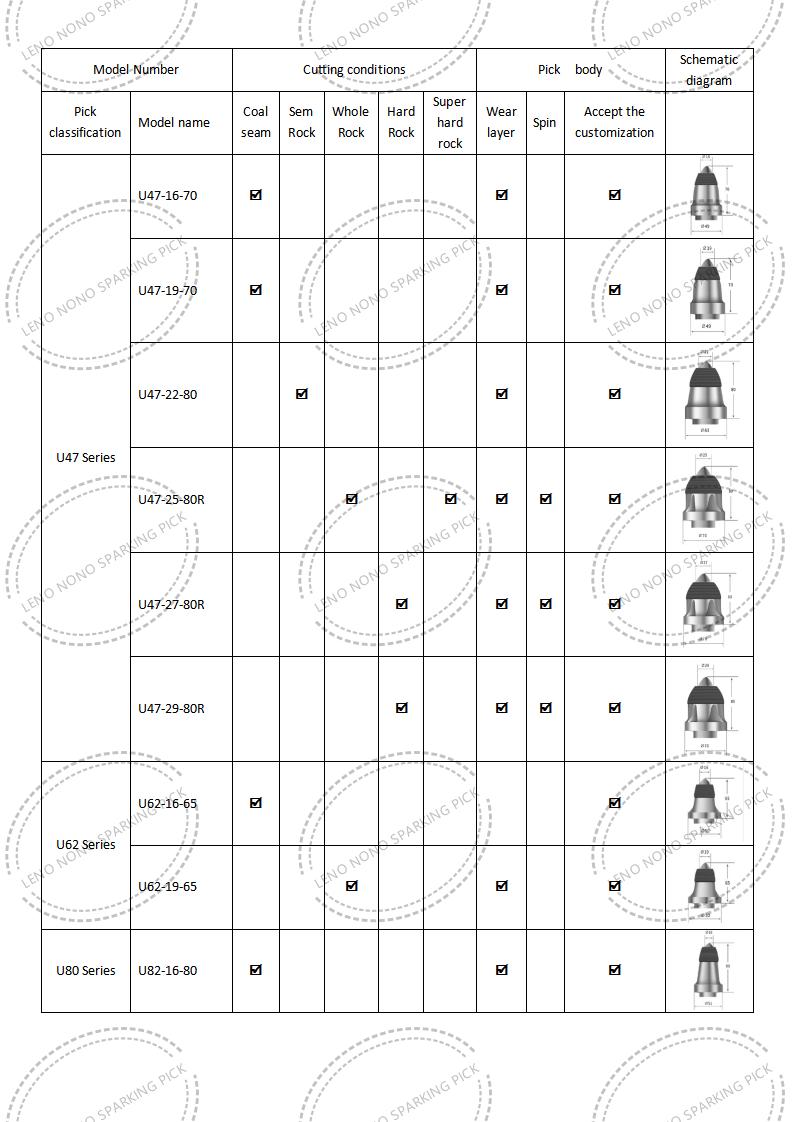

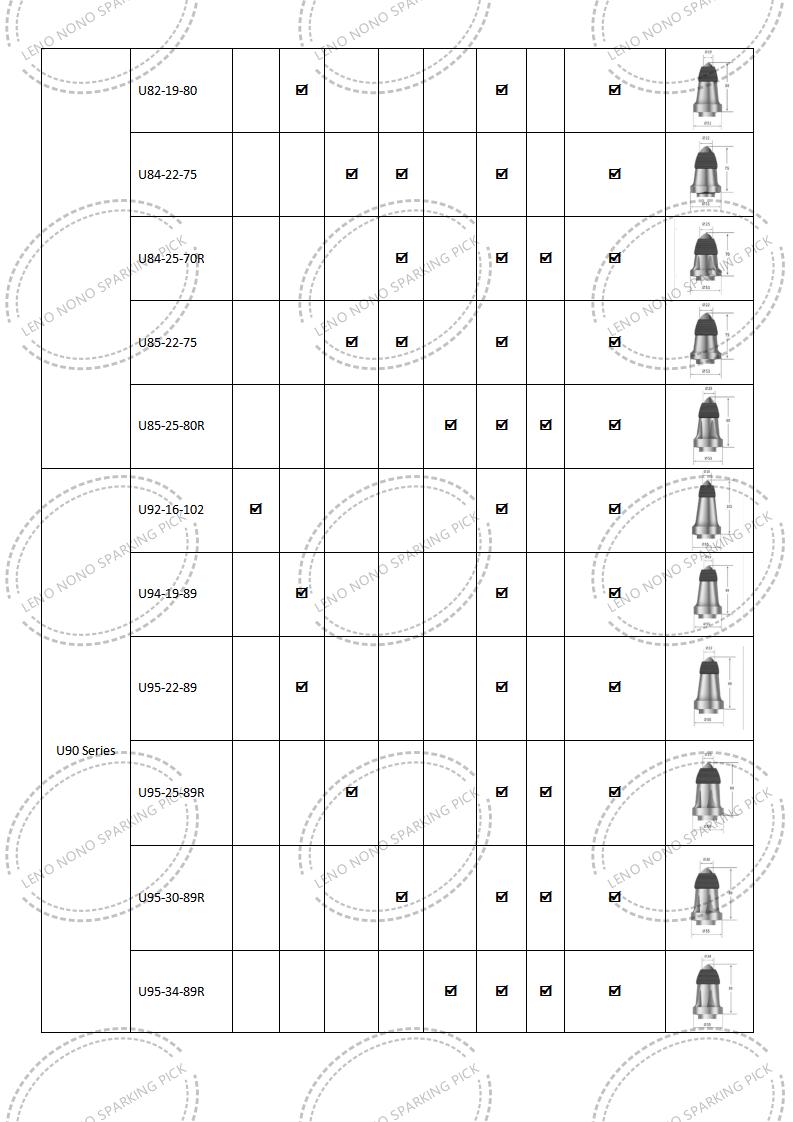

The selection range of hard alloy head is 12mm-34mm;

Supporting medium and high-power shearer drums for coal falling; Suitable for medium/heavy working conditions;

Widened pick shoulder design, better protect the tooth seat and pck bushing;

Strong penetration, low wear and high stability;

Wide and large tooth head, high cutting efficiency; Resistance to high temperature sparks, easy replacement;

The shearer pick is the main cutting tool on the shearer drum. It is installed on the shearer drum in conjunction with the pick base and gear sleeve. It is one of the vulnerable parts of coal falling. The quality of the shearer pick is directly related to the efficiency of the shearer operation, the power consumption, the production capacity, the stability of the work and the service life of the supporting parts.

LENO Plasma Technology Application Department is a professional high-end pick cutter research and development manufacturer, has a strong scientific and technological research and development elite team, and the pick production equipment is currently the most advanced automatic brazing and quenching integrated production line in China. In the production process of picks, each level is checked to ensure the high standards and high quality of LENO picks!

LENO U92 series shearer picks are suitable for medium and high-power shearers, which can meet medium-heavy working conditions; the imported tungsten carbide wear-resistant layer further enhances the wear resistance of the product and improves the use of the product Life; using insulating material, no sparks are generated during cutting of the pick, and the construction operation is safer; the widened and enlarged tooth shoulder design provides great protection for the tooth seat and pick bushing, and extends the service life of the accessories; the surface of the product is smooth and flat, without Visible cracks, dents, etc., the product has been rust-proofed before leaving the factory, and it will not rust for long-term storage.

Adopt clever design to increase the strength of the product;

Absorb the tungsten carbide wear-resistant layer to further improve the wear resistance of the product and increase the service life of the product;

The standard tooth shoulder design tooth seat provides great protection so that the life of the tooth seat can also be improved;

The products are produced with special materials and manufacturing processes, no sparks are generated during pick cutting, and the production operation is safer;

The surface of the product is clean and smooth, without visible traces, dents, etc. The original anti-rust treatment of the product prevents rust for a long time.

| Position | Material |

| Carbide head | high-end tungsten alloy alloy |

| Wear-resistant layer | Imported tungsten carbide |

| Solder and flux | Imported copper-based solder and flux |

| Pick body | high-quality 42CrMo alloy steel |

| Item | Target | Parameters |

| Surface hardness | Alloy head | > 92HRC |

| Wear-resistant layer | > 61HRC | |

| Pick edge | >50HRC | |

| Pick handle | > 45HRC | |

| Impact toughness | Alloy head | >2800J/cm² |

| Pick edge | ≥59J/cm² | |

| Shear strength of welding seam | Pick body and alloy head | ≥195MPa |

The service life of pick cutters is 1.5~2 times higher than similar products;

Picks are guaranteed to be of imported quality, and the price is much lower than imported

Super-hard rock picks can be used in F10 super-hard rock formations

Tunnel teeth effectively impact 120MPa hard rock roadway/large section tunnel rock formation

The cemented carbide we use is made of tungsten carbide and cobalt. Expensive raw materials ensure the best sintering ability and help us make pick tools with high hardness and wear resistance. This pick can withstand a very Strong shock load.

Leno leading wear-resistant coating technology allows every pick to have a high degree of wear resistance. In the application, the spin design of the pick will play a huge role in ensuring the uniform wear of the product and extending the life.

Wear-resistant pick cutters have a complete range of models and provide cutting solutions for multiple main application fields, multiple complex geological environments, and multiple mining machinery and equipment.

From the warehouse body and alloy warehousing to surfacing and heat treatment, to shot blasting, all production steps are optimized to the details and are supervised and controlled.

From the beginning of the storage of tooth bodies and alloys to surfacing and heat treatment, to shot blasting, all production steps are optimized to the details and are supervised and controlled.

1. Quick response, for any of your inquiries, we will reply to you within 24 hours.

2. We offer OEM service. Your logo can be printed on the roadheader picks.

3. We have rich experience in this field, and do R&D work for you.

4. Normal model can be produced within 10 days. Fastest than ever.