Friendship Machinery Co., Ltd |

|

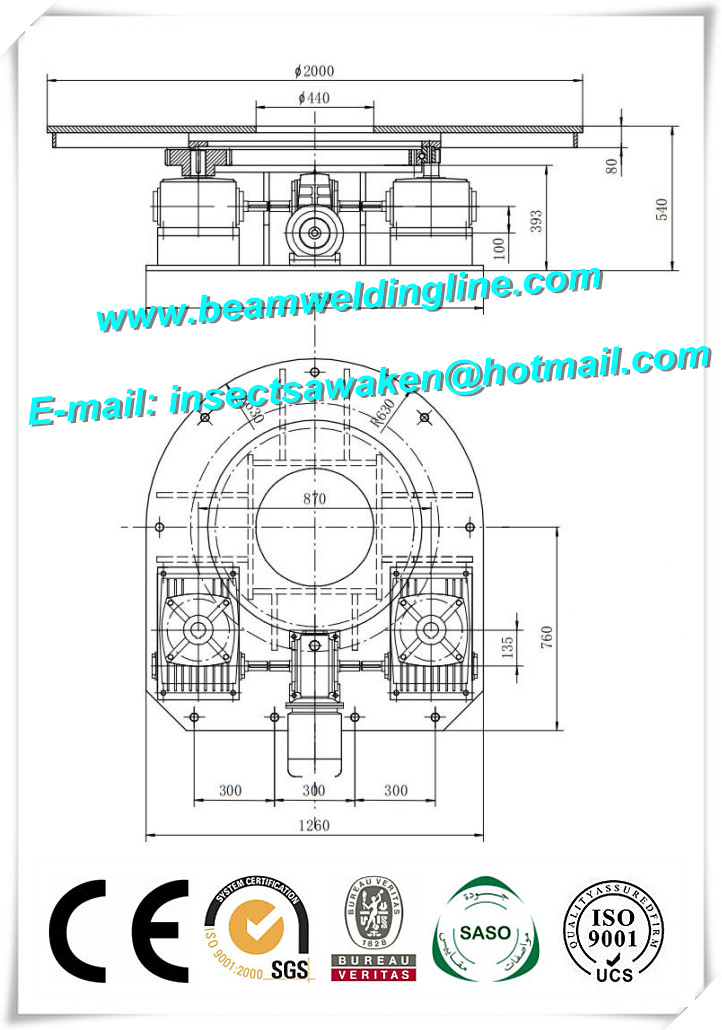

Automatic Welding Machine Revolving Table / Floor Turntable Positioner

1. Equipment overview

Floor turntable

positioner is a kind of equipment that can make the work turn

around 360 ° in horizontal direction. It turns infinite with

practical and reliable, and turns smoothly and applicable scope,

and the operation is simple etc, and it is the typical of the

auxiliary equipment in the process of welding process. It can also

be widely used for the cutting, grinding, assembly, especially

suitable for the larger work-piece to turn around, and it is one of

the ideal equipment to improve the degree of automation and

efficiency.

2. Technical specification

● Maximum load weight: 3000kg

● Table diameter: φ2000mm

● Table connection form: M24×6 (T-slot)

● Rotary speed: 0.1-1rpm

● Rotary motor power: 1.5kw

● Height above ground: 540mm

3. Structure theory

This equipment is mainly

composed of frame, table, swing mechanism, conductive device and

electric control etc.

Frame, table: the frame

is the box shape weldment. The Frame and the table are all welded

structure, such as strength requirement according to welding, and

after welding annealing heat treatment were performed, get rid of

the welding stress and effectively preventing deformation of the

processing. Mesa have concentric rod, facilitate work-piece as the

benchmark for reference. All welded joints press the uniform

strength welded joint to carry on the welding, and after welding

annealing heat treatment are performed. The table has concentric

ruler to facilitate the reference as the benchmark.

Swing mechanism: the

swing mechanism is located between the frame and the table, and it

is mainly composed of speed reducer, motor, rotary bearing etc. The

motor adopts domestic brand, stable and reliable. The reducer

adapts the double worm gear reducer, with self-locking function and

larger output torque. Rotary mechanism is driven by the motor,

through the reducer to slow down, and the output shaft drives the

workbench back again. Turning speed also can be made of conversion

stepless speed, making the table in the range of 10 times of

variable speed, to meet the different sizes of work-piece.

Work-piece in the

welding process with the ground wire should be connected with the

conductive device directly, and the conductive device should be

connected with the table, to make sure that the whole welding

progress can form loop constantly. The conductive device is the

sliding conductive bearing with conductive pastes, and the maximum

current can be up to 400A.

Electrical control

system: it is mainly composed of control box and operation box.