Allwin Machine & Equipment Co.,Ltd |

|

Verified Suppliers

|

|

High Output Silicon Carbide Horizontal Bead Mill With 250L Complex Structure In MLCC, Non Metallic Grinding

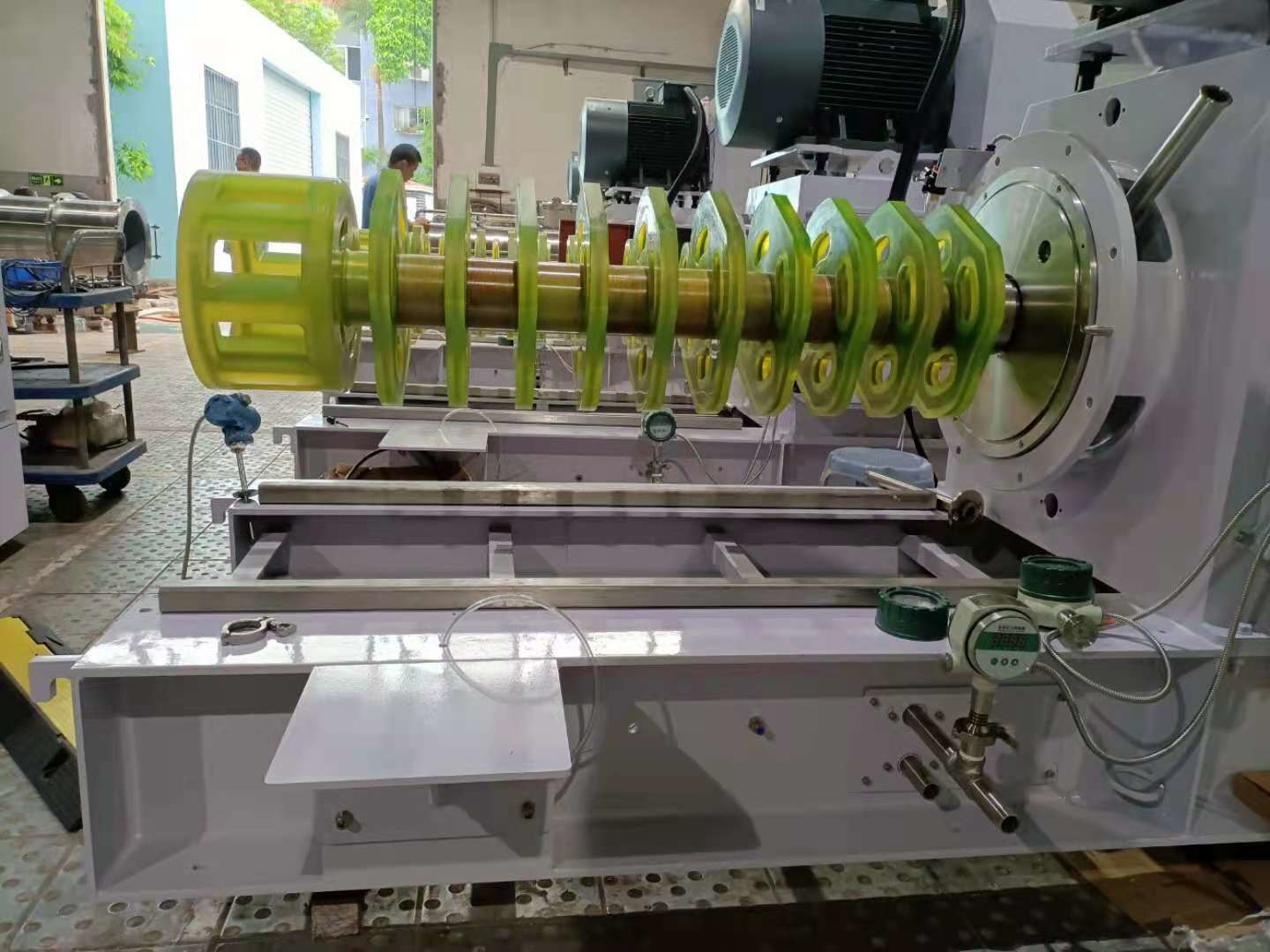

ALLWIN has been founded for more than 28 years, has massive experience in manufacturing bead mill machines.Also manufactured with advanced equipment like American imported HAAS 1600 plus 4 axis CNC, which can ensure rather great concentricity of key parts with one time processing in 360° rotation, insuring steadily operation with longer worklife, nearly no noisy. and also other high advanced processing machines are used like plasma cutter, auto weilding robot, etc.

While, for many customers,how to choose an appropriate bead mill,that's a question. We can give some advices.

1. grinding is a key processing in whole procedure,the fineness must can basicly reach your requirement after finished.

2. the output efficiency is a core element. we also hope machines could help customer to gain the maximum values with the most massive output capacity.

3.mill machines are serrious of enery comusption , energy saving is a great advantage to lower the producing cost.

4.other considerations like human labor or customized service will be great if machines are capable.

Most bead mills are suggested according to customer's different requirement and capability, and finally customers get great usage experience, allwin also win great reputation in peers and customers.Inner cylinder, it's an very important parts of grinding with massive touching space when operation, we often advice according to following referrence.

1. ceramics cylinder bead mill with high efficiency, lower temperature is suitable for customers with high standard and longterm vision;

2. bead mills with inner cylinder material 9Cr18Mo wearable stainless steel is more suitable for normal standard products;

3. the PU coated with stainless steel mills are much fitable for no pollution griniding with comparatively higher temperature.

All of them are reasonable, just choose the right mills. All mills owns one year warranty, vulnerable spare parts are exclusive. The motor power can be choosed by your decision or our enginner's consideration.

The technical data:

| No | main parameters | SP250 | Note |

| 1 | Explosion-proof motor kW | 75kW ( Ex) | non explosion for choice |

| 2 | Effective volume of grinding chamber (L) | 250 | other size of volume can be customized |

| 3 | Water pressure (MPa) | 0.3 | |

| 4 | Cooling water consumption (L/min) | 3.0-3.5m3/h | Advise offer the Cooling water less 10°C |

| 5 | Dimensions:L*W*H (mm) | 2550*8501200*2140 | |

| 6 | Weight (kg) | 2800 |

The technical parameters

| No | Main parts | SP250 | Notes |

| 1 | Outer cylinder | 304 stainless steel | |

| 2 | Internal cylinder | silicon carbide ceramics | other materials are optional(wearable steel, stainless steel, PU,etc) |

| 3 | Dispersing shaft | 40Cr with hard chromium plating | Brand: NSK |

| 4 | Dispersing disk | Stainless steel coated with PU | other materials like wearable steel, stainless stell, etc are optional |

| 5 | Mechanical seal | Double Mechanical seal with Pressure of 0.45 Mpa | |

| 5 | Feeding and discharging end covers on the cylinder | 304 stainless steel | |

| 6 | Turbine centrifugal separator | 304 stainless steel coated with PU | other materials like wearable steel, stainless stell, etc are optional |

| 7 | Static discharge screen ring | 304 stainless steel screen ring with 304.Gaps: 0.3-0.8mm according to required fineness and size of grinding medium | |

| 8 | Mechanical seal | Intelligent double mechanical seal with mandatory lubricating-cooling system | |

| 9 | Feeding pump | 1.5" aro diaphram pump | Brand: Ingersoll Rand |

| 10 | Operating control | button type or PLC (optional) |

Applications

250L Wet grinding machine ( bead mill/ grinding mill/ sand mill) are widely applicated in following industries:

Paint, coat , non metallic mine( titanium dioxide, barium sulfate, mica iron oxide ,tombarthite ,etc), cholocate,mineral, MLCC, etc.

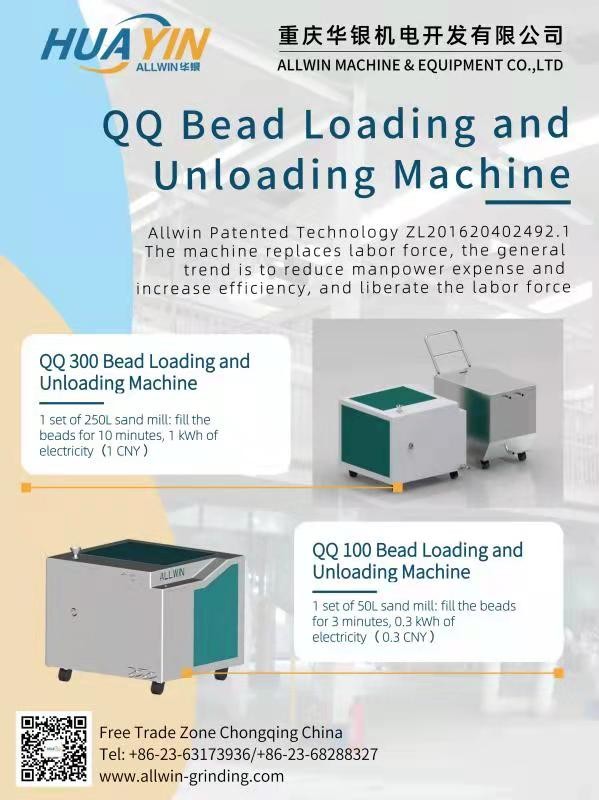

Other related products