Shenzhen Chebao Technology Co., Ltd |

|

Verified Suppliers

|

|

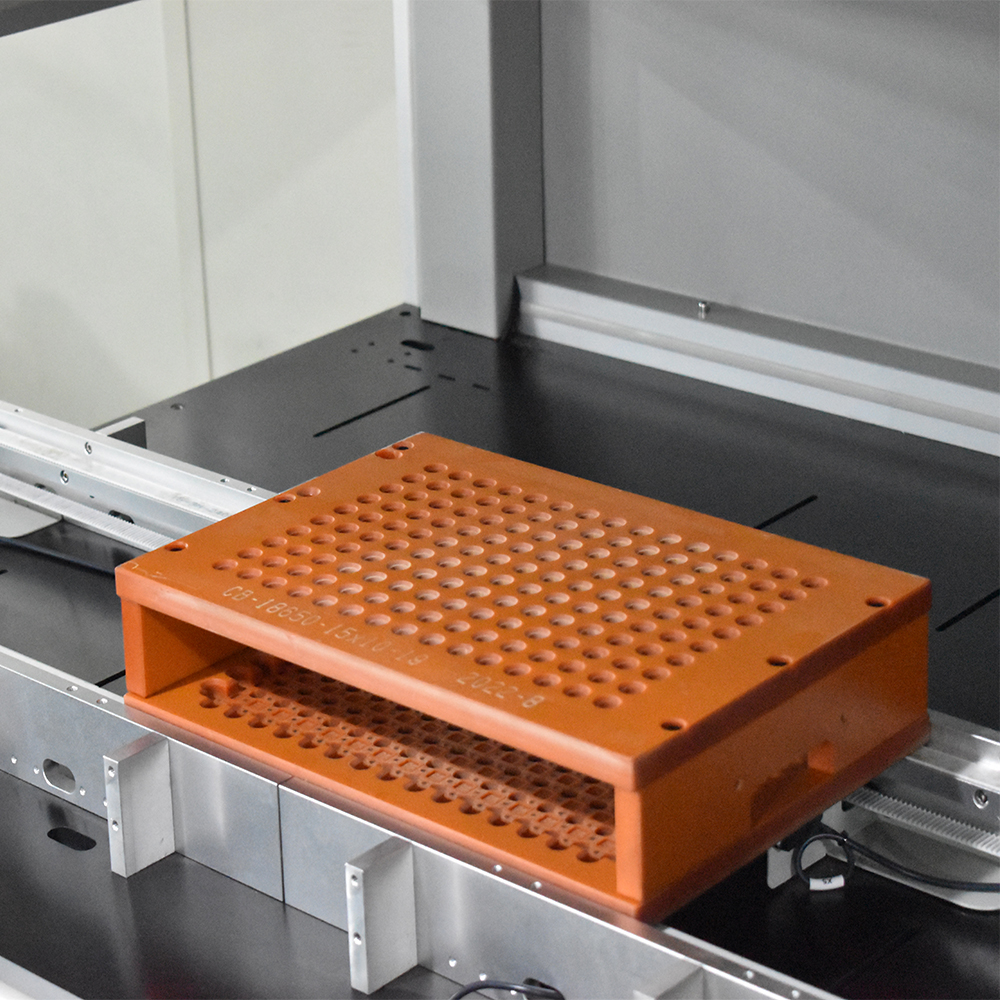

Cylindrical Battery Pack Positive And Negative Electrode Testing Equipment

● A CCD vision inspection equipment using machine vision technology based on CCD industrial camera for inspection of multi-purpose vision inspection system

● Applicable to a variety of core polarity character measurement,

saving labour costs, and able to carry out highly repetitive work.

● CCD vision inspection can work long time to stable, good

reliability, high detection accuracy with manual debugging

function, can be fine-tuned for each detection and monitoring area

parameter preservation, but also for the use of the overall offset

function to adjust.

● With a counting function, you can count the number of OK / G

● With fixture automatic in place detection function

● Support multi-lock board comparison, the maximum support for 100

groups of templates.

● Adopt light height adjustable design, can be used in a variety of

lighting environment.

| Testing range | 250*400MM | Lens pixel | 500W pixel HD lens |

| Detection efficiency | 3-5s/PCS | Accuracy | 99.99% |

| Transmission mode | Belt transmission | Weight | 150KG |

| Display mode | Graphical display | Dimensions | 1200*1000*1870MM |

| Device system algorithm | CHEEBO CCD special system algorithm | Application scenario | Polarity detection of various cells |

| Detection algorithm | Positioning, measurement, flatness, contrast, presence or absence | Reminder | Sound and light alarm, wrong position color change |

Workflow of detection OK: the fixture is fed from the feed port of the belt line -- the belt stops running when it reaches the detection position --

waiting for detection -- detection OK -- Manually close the fixture cover -- click the button to close the cover -- the fixture flows out

Detection NG workflow: the fixture is fed from the belt line feed port -- arrives at the detection position and the belt stops running -- waits for

detection -- Detects NG -- determines the problem point according to the software diagram -- performs manual intervention -- clicks the manual

start detection button -- detects OK -- manually closes the fixture cover -- clicks the closing cover finish button -- the fixture flows out

1.Comprehensive multi-angle fill light, HD photo head, industrial-grade camera with high detection accuracy, fast speed and high efficiency, zero error.

2. Large detection range

Support a variety of cell models, detection range: 250*400mm. Can

be customized according to requirements.

Q: What's your minimum order quantity?

A: We don't have a minimum order quantity. Whether it is an order of 1 or 100, we will wholeheartedly support you.

Q: How do I install and run the machine?

A: Our technicians had installed the machine before shipment. For the installation of some widgets, we will send out detailed training videos and user manuals randomly. 95% of customers can teach themselves.

Q: How can I do if the machine goes wrong?

A: If you encounter such problems, please contact us as soon as possible. Do not try to repair the machine by yourself or others. We will respond as soon as possible within 24 hours to solve your problem.

Q: How does your factory do in terms of quality control?

A: Quality comes first. More than 20 tests will be performed on each unit. After all the tests are passed, our QC will test the welding performance.

Looking forward to your consultation, we will provide you with the best quality service throughout the process!!!