Shenzhen Chebao Technology Co., Ltd |

|

Verified Suppliers

|

|

Multi Pulse Power Manual Lithium Spot Welding Machine Pneumatic For 18650 Battery

Power lithium-ion battery pack welding, 3C lithium-ion battery pack welding, Ni-MH battery pack welding, hardware parts welding, electronic and

electrical parts welding, terminal welding, stainless steel parts welding, metal jewelry welding, copper products welding, aluminum products

welding, etc. It is also suitable for product maintenance, sampling and other welding work.

● Double section multi-pulse design, improve energy output waveform, improve welding capacity.

● Microcomputer technology control, monitoring power grid voltage,

automatic compensation.

● Digital LED display, device parameter adjustment is convenient

and intuitive, the device can pre-store multiple programs.

● Stable equipment performance, mature technology, cost-effective,

well received by users.

● High quality tempered glass is used to protect the desktop from

wear during welding.

● Vertical spot welding method for welding, manual control of the

depth of pressure.

● Compact structure, small volume, large power, large industrial

circuit design, long welding safe and reliable.

Power on -- display 600 OE self-test screen -- press the up arrow to enter the system -- Place the product to be welded on the desktop --

Step on the pedal -- push down the welding head -- spot welding completed -- return the welding head

| Welding thickness | 0.02-0.15MM | Welding power supply | Multiple-pulse |

| Welding mode | Single side double point horizontal welding | Table top and weld head height | 130MM (Maximum pitch adjustable) |

| Supply current | 2800A | Welding speed | 200P/M |

| Spot welding method | Bump welding/tip welding | Welding pressure | 5KG/F |

| Equipment power | 7KW | Equipment size | 600*900*1150MM |

| Driving mode | Pneumatic | Machine Weight | 48KG |

| Power source specification | Single-phase 220V50/60HZ | Application scenarios | Battery welding |

1. Cylinder drive

The air source interface is connected to the pressure regulator to adjust the air source pressure and filter the water. The gas is sent to the solenoid valve, which controls the gas drive cylinder and drives the welding head.

2. Foot on switch drives welding

Metal iron shell, not easy to damage, durable. Silver alloy electric shock, stable and durable. Humanized foot step non-slip design.

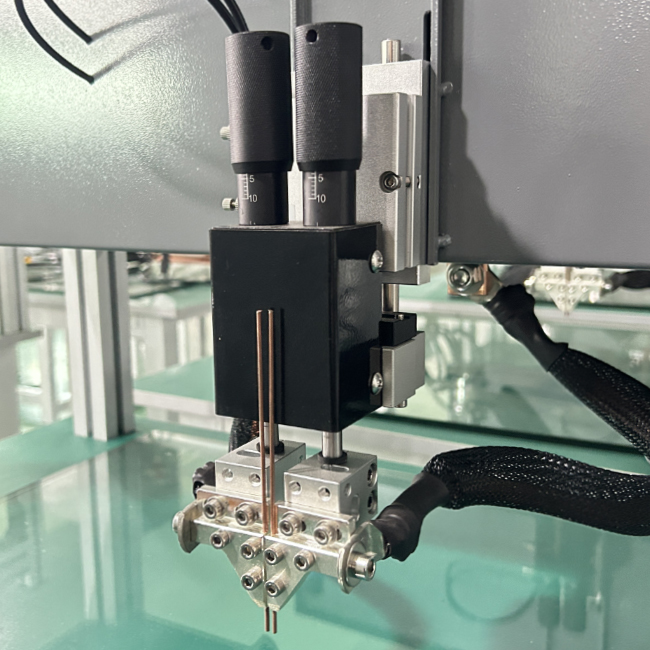

3. Pneumatic precision welding head

Horizontal welding structure, double linear guide design, left and right pressure can be adjusted separately. Built-in pressure sensor, precise control to apply stable pressure.

Q: I don't know which one is right for me?

A: Please tell us the following information

1) Battery model and type.

2) Welding material and welding thickness

3) Commercial industry: We have a lot of sales experience and can provide you with advice.

Q: How do I install and run the machine?

A: Our technicians had installed the machine before shipment. For the installation of some widgets, we will send out detailed training videos and user manuals randomly. 95% of customers can teach themselves.

Q: What's your minimum order quantity?

A: We don't have a minimum order quantity. Whether it is an order of 1 or 100, we will wholeheartedly support you.

Q: How does your factory do in terms of quality control?

A: Quality comes first. More than 20 tests will be performed on each unit. After all the tests are passed, our QC will test the welding performance.

Q: How can I do if the machine goes wrong?

A: If you encounter such problems, please contact us as soon as possible. Do not try to repair the machine by yourself or others. We will respond as soon as possible within 24 hours to solve your problem.