Shenzhen Best Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Automatic power battery assembling line AC380V 50/60HZ customized with 10000A transistor double sides spot welding

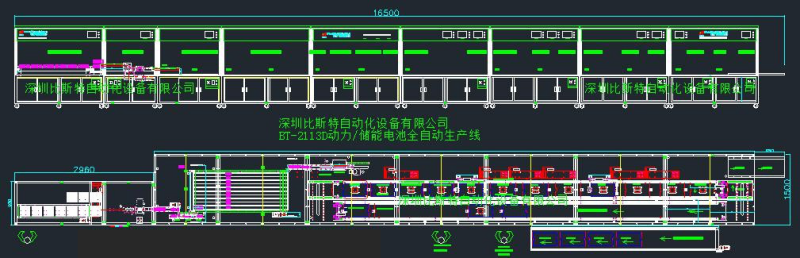

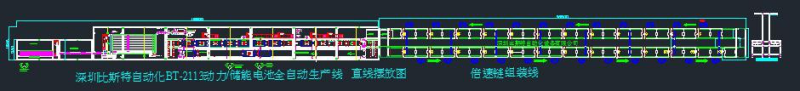

Equipment name: Automatic production line of power energy storage battery pack

Specification model: BT-2113-18650

I. Scope of application and function introduction

1. Scope of application:

Mainly used in automotive battery modules. Fully automated production of power battery, energy storage battery, power tool battery pack and other application batteries

2. Only 3 operators are required to operate the battery pack from the box to the completion of welding. Due to the difference in technology, some positions cannot be operated by machines, so the number of operators varies

3, optional cell scan code function, the state of the cell data into the bracket or combined battery, the battery data can be traced, can also be used as cell OCV comparison, select defective products

4, 4 axis Yamaha robot automatic support, stable and reliable performance

5, using Hikvision series CCD battery polarity identification, to ensure that the battery into the bracket without polarity error phenomenon.

6, the use of cell spacing combination mechanism, suitable for different spacing of the battery, to solve the problem of opening multiple fixture due to different spacing

7. Use 2 sets of laser to clean the stains on the anode and cathode surfaces of the cell to ensure the welding quality

8. Device support functions:

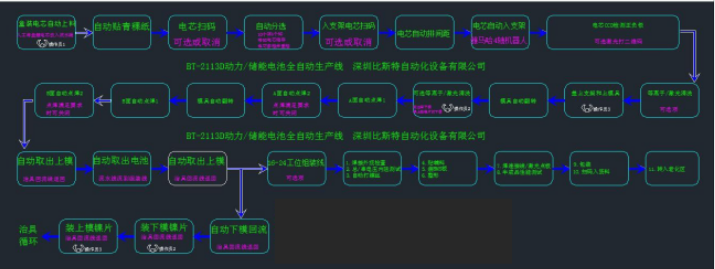

18650 Automatic boxed cell (10*10) automatic feeding → automatic veneer → automatic code scanning →

Automatic sorting (10 grades OK, First gear NG) → automatic cell sorting → automatic scanning → robot into the bracket →CCD vision positive and negative pole detection → laser cleaning Side A → mold turnover 1→ Spot welding on Side A 1→ Spot welding on side A 2→ mold turnover 2→ Spot welding on side B 2→ spot welding on side B 2→ Automatically take out the cover → automatically take out the battery → battery semi-finished assembly line (spot welding appearance detection → paste accessories → protection plate connection → shaping → comprehensive performance test, etc.)

9. Maximum stroke of the equipment: 430MM in the X-axis direction, 270MM in the X-axis direction, 21 cores in the X-axis direction and 13 cores in the X-axis direction at 20.5mm spacing

Production efficiency: 5000-6000pcs /H