ZhongHeng Machine Manufacture Co.,Ltd |

|

High Configuration

Corrugated sheet / IBR Roof Panels Roll Forming Machine

This machine is exported to Cameron,Feeding width is 1000mm

and effective width is 800mm and

835mm.Double-layer for the corrugated sheet and IBR sheet .

1.Specifications

| Roller steps | 14/15 |

| Dimension | 7200*1600*1550mm |

| Weight | 4.5t |

| Feeding width | 800mm/835 |

| Forming thickness | 0.35-0.6mm |

| Large frame | 400mm H-Beam |

| Diameter of roller | Φ70mm |

| Middle plate | 16-25mm |

| Chain Size | 1 inch |

| Voltage | 380V 50HZ 3 phases or customized |

| Motor power4 | 4kw |

| Pump station power | 3kw |

| Transducer power | 5.5kw |

| Cutting system | Hydraulic cutting(avoiding noise and smooth cut) |

| Material of cutting | Cr12 |

| Control system | PLC brand :Panasonic |

| Length error : ±2mm | |

| Production capacity | 10-15m/min |

| Warranty | 1 year and we provide technical support for whole life, and overseas service |

| Maintain | Easily :Timely adding oil |

| Payment terms | 30% in advance, the balance before delivery |

| Package | Standard package |

| Delivery | 35 days after receiving the deposit |

2.Components Details

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 350# steel. More stable and no shaking. |

| Middle Plate | 16mm. We use thicker plates to ensure stability |

| Forming Steps | 16, according to the drawing. |

| Shaft Material | Φ70 mm, high grade 45# steel. |

Treating process: tempering- finish turning, | |

Cutting | Cr12, hardness HRC60-62. |

| Treating process: heat treatment- plane abrasion- wire electrode cutting. |

3.Electric Components

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 7 inch touch screen, easy to operate. |

| PLC | Delta DVP14ES |

Well-adapted to various conditions, such as moisture, | |

| Frequency Converter | Delta VFD-M. It has the advantage of slowing down before cutting, |

Length | Omron, made in Japan. |

| It features with high accuracy and stability. |

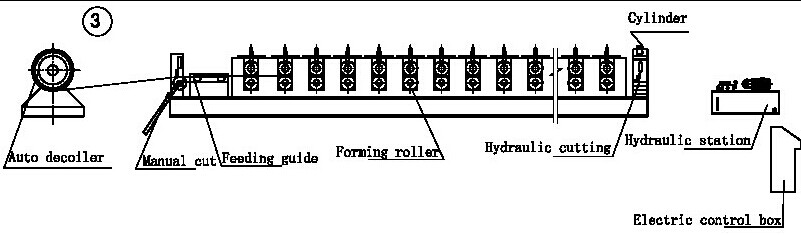

4.Flow chart

Manual Decoiler—Roll Forming Machine—Computer Control

System—Hydraulic Control System—Form Cutter

5.Components of line

1) Manual De-coiler

------------------------------------------------------ 1 set

2) Guiding

Device--------------------------------------------------------- 1

set

3) Roll Forming

System--------------------------------------------------- 1set

4) Cutting

Device----------------------------------------------------------

1set

5) Hydraulic

System------------------------------------------------------- 1 set

6) PLC Control

System-----------------------------------------------------1 set

7) Run out table

----------------------------------------------------------- 1 set

7. Contact information

8. Machine pictures