ZhongHeng Machine Manufacture Co.,Ltd |

|

Auto Drywall Metal Furring Channel Roll Form Machine,Construction Building Machinery

Description

Light steel keel forming machine with steel as a raw material, by continuous cold rolling molding to produce complex profiles section, type multiple, versatile. We can according to customer design, manufacture different specifications of cold-formed, paint unit equipment.

Light steel keel molding machine is used to plaster board, gypsum board and other decorative finishes lightweight board made of non-load-bearing walls and roof of the building style decoration, a variety of decorative building roof shape, inside and outside the building wall and ceiling scaffolding base material. Used in hotels, terminals, bus terminal, railway stations, theaters, shopping malls, factories, office buildings, old building renovation, interior decoration settings, roof and other places.

2 Detailed picture

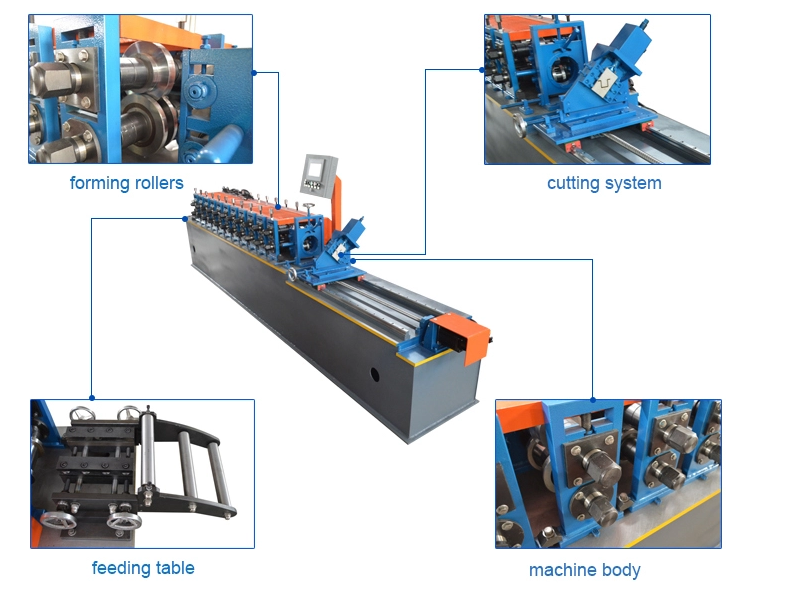

3. Components of machine

| No. | Name | Qty |

| 1. | De-coiler | 1 Set |

| 2. | Roll Forming Machine | 1 Set |

| 3. | Hydraulic Cutting Device | 1 Set |

| 4. | PLC Control Box | 1 Set |

| 5. | Hydraulic Pump | 1 Set |

| 6. | Output table | 1 Set |

Decoiler

| Type | Manual type(standard) | Hydraulic type(option) |

| Photo | ||

| Width | 300mm | 500mm |

| Capacity | Max 3tons | From 3-5 tons |

| Inner diameter | φ450-550mm | φ450-550mm |

| Outer diameter | φ1500mm | φ1800mm |

roll forming

| Item | Parameter detail | ||||||||

| Processing Material | GI and PPGI | ||||||||

| Material thickness | 0.4-0.8mm | ||||||||

| Machine frame | 360#H steel, Adopt diagonal line welding, leveling instrument measurement to make sure the final frame is high-precision | ||||||||

| Machine siding panel |

| ||||||||

| Forming stations | 10-22 stations(according to the profiles) | ||||||||

| Machine rollers | high grade Cr12 steel,plated hard chroming with thickness 0.05mm Processing way:cutting--drilling--CNC lathing--quenching--CNC lathing--chroming | ||||||||

| Machine Shaft | φ60-70mm high garde No.45 steel after treatment, | ||||||||

| Machine spacers | CNC lathing in high-precision | ||||||||

| Machine bearings | China Haerbin bearing or SKF international bearing(option) | ||||||||

| Driving system | Gear or gear box(option) | ||||||||

| Machine power | 3kw-5.5kw(according to the profiles) | ||||||||

| Machine working speed | 8-12m/min or 10-30m/min(option) | ||||||||

| Machine adjust type | After machine installation, we will test it ourselves, compare with the profile drawing, the difference is controlled in 0.5mm |

Cutting

| Type | Mould cutting type |

| Blade material | Cr12mov quenching and grinding |

| Frame processing | the whole bottom frame is grinding for high-precision |

| Blade processing | wire-electrode cutting, but the upper balde can not be straight. this is technology |

| Working | Hydraulic type |

Stacker

| Type | Manual | Auto(option) |

| Length | 1.5m-2m | 6m or 12m |

PLC

| Main item | Parameter detail |

| PLC | Delta(standard) or according to your request |

| Inverter | China brand(standard) or according to your request |

| Touch screen | Mcgs(standard) or according to your request |

| Encoder | China brand(standard) or according to your request |

| Voltage/HZ/Phase | 380v/50-60hz/3phase |

Hydraulic pump

| Main Item | Parameter detail |

| Motor | 3kw China brand or according to your request |

| Pump | China brand or according to your request |

| Solenoid valve | China brand or according to your request |

| Cooling system | Cooling fan |

Details

Machine pictures

Free to Contact us