ZhongHeng Machine Manufacture Co.,Ltd |

|

galvanized steel profile drywall rolled omega forming machine with high speed

Description

Drywall (also known as plasterboard, wallboard, gypsum panel, sheet rock, or gypsum board) is a panel made of calcium sulfate dihydrate (gypsum), with or without additives, typically extruded between thick sheets of facer and backer paper, utilized in the construction of interior walls and ceilings.[1] The plaster is mixed with fiber (typically paper and/or fibreglass or asbestos), plasticizer, foaming agent, and various additives that can decrease mildew, increase fire resistance, and lower water absorption.

Drywall construction became prevalent in North America as a speedier alternative to traditional lath and plaster

2 Detailed picture

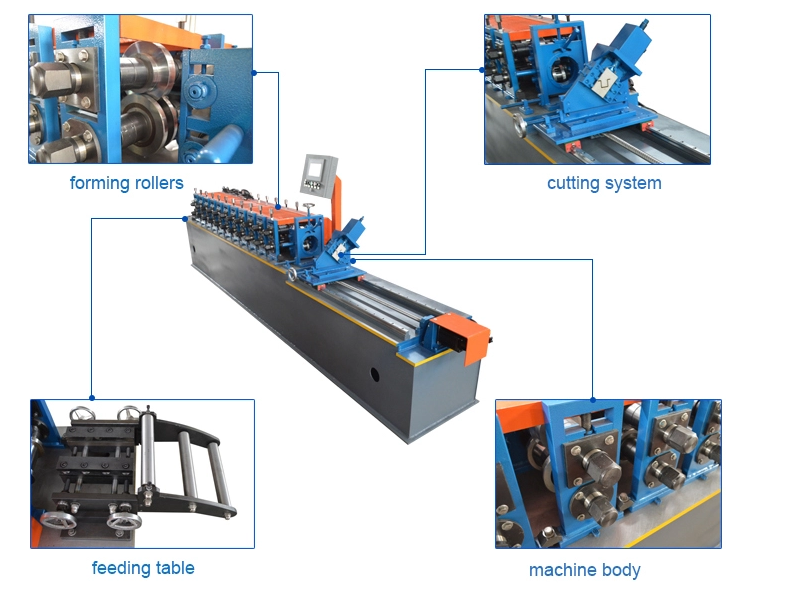

3. Components of machine

| No. | Name | Qty |

| 1. | De-coiler | 1 Set |

| 2. | Roll Forming Machine | 1 Set |

| 3. | Hydraulic Cutting Device | 1 Set |

| 4. | PLC Control Box | 1 Set |

| 5. | Hydraulic Pump | 1 Set |

| 6. | Output table | 1 Set |

Decoiler

| Type | Manual type(standard) | Hydraulic type(option) |

| Photo | ||

| Width | 300mm | 500mm |

| Capacity | Max 3tons | From 3-5 tons |

| Inner diameter | φ450-550mm | φ450-550mm |

| Outer diameter | φ1500mm | φ1800mm |

roll forming

| Item | Parameter detail | ||||||||

| Processing Material | GI and PPGI | ||||||||

| Material thickness | 0.4-0.8mm | ||||||||

| Machine frame | 360#H steel, Adopt diagonal line welding, leveling instrument measurement to make sure the final frame is high-precision | ||||||||

| Machine siding panel |

| ||||||||

| Forming stations | 10-22 stations(according to the profiles) | ||||||||

| Machine rollers | high grade Cr12 steel,plated hard chroming with thickness 0.05mm Processing way:cutting--drilling--CNC lathing--quenching--CNC lathing--chroming | ||||||||

| Machine Shaft | φ60-70mm high garde No.45 steel after treatment, | ||||||||

| Machine spacers | CNC lathing in high-precision | ||||||||

| Machine bearings | China Haerbin bearing or SKF international bearing(option) | ||||||||

| Driving system | Gear or gear box(option) | ||||||||

| Machine power | 3kw-5.5kw(according to the profiles) | ||||||||

| Machine working speed | 8-12m/min or 10-30m/min(option) | ||||||||

| Machine adjust type | After machine installation, we will test it ourselves, compare with the profile drawing, the difference is controlled in 0.5mm |

Cutting

| Type | Mould cutting type |

| Blade material | Cr12mov quenching and grinding |

| Frame processing | the whole bottom frame is grinding for high-precision |

| Blade processing | wire-electrode cutting, but the upper balde can not be straight. this is technology |

| Working | Hydraulic type |

Stacker

| Type | Manual | Auto(option) |

| Length | 1.5m-2m | 6m or 12m |

PLC

| Main item | Parameter detail |

| PLC | Delta(standard) or according to your request |

| Inverter | China brand(standard) or according to your request |

| Touch screen | Mcgs(standard) or according to your request |

| Encoder | China brand(standard) or according to your request |

| Voltage/HZ/Phase | 380v/50-60hz/3phase |

Hydraulic pump

| Main Item | Parameter detail |

| Motor | 3kw China brand or according to your request |

| Pump | China brand or according to your request |

| Solenoid valve | China brand or according to your request |

| Cooling system | Cooling fan |

Details

1. Metal stud and track roll forming machine is the most common

machine to produce cold rolled C stud and u track profiles. It is

the most popular machine in light building construction area.

2. We are professional manufacturer of metal stud and track roll

forming machine and have lots successful experiences. Our roll

forming machine for C stud and u track can make the C stud and u

track from thickness 0.5mm-1.2mm. Very portable!

3. The whole line of metal stud and track roll forming machine

include the automatic decoiler or manual decoiler for 3ton coils ,

roll forming machine include the guide& feeding device, cutting

blade drived by hydraulic power and auto stacker or manual stacker

for finished products.

4. This line can be automatic running by inputting the length and

batches in the PLC system.

5. The strong H beam base is treated to avoid the vibration when

working.

6. All the rollers are hardness quenched to guarantee the life

7. The human computer interface operate system will save human

source to operate the production line.

Machine pictures

Free to Contact us