ZhongHeng Machine Manufacture Co.,Ltd |

|

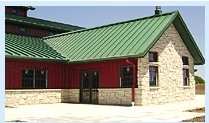

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands,

ancient architectures and modern villas

3.Working Flow of Roll Forming Machine

A Sheet Specifications

| 1. | Coil Type | Roll Forming Machine full-automatic single layer corrugated profile roofing sheet color steel roof |

| 2. | Width | 1220mm |

| 3. | Thickness range | 0.3mm-0.8mm (max) |

| 4. | Yield stress(mm) | Q235 |

| 5. | Effective width | 1010mm |

B Components Details

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 350# steel. More stable and no shaking. |

| Middle Plate | 16mm. We use thicker plates to ensure stability of our products. |

| Forming Steps | 11-16, according to the drawing. |

| Shaft Material | Φ70 mm, high grade 45# steel. |

Treating process: tempering- finish turning, high rigidity, hard to deform. | |

Cutting Blade Material | Cr12, hardness HRC60-62. |

| Treating process: heat treatment- plane abrasion- wire electrode cutting. |

C. Electric Components

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 7 inch touch screen, easy to operate. |

| PLC | Delta DVP 14ES |

well-adapted to various conditions, such as moisture, electromagnetic disturbance. | |

| Frequency Converter | Delta VFD-M. It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

Length Measurement Device | Omron, made in Japan. |

| It features with high accuracy and stability. |

| Type | Roll former for roofing |

| Shearing Thickness | Up to Max. 0.8mm |

| Thickness | 0.4mm-0.6mm |

| Feeding Width | 1250mm |

| Frame Design | Wall-plate-frame-design /New-stand-frame-design |

| Roll Stages | 14 stages |

| Material Of Forming Roller | 45# steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ75mm |

| Main Motor Power | 5.5KW |

| Max. Line Speed of Roll Former | 15m/min (Higher speed is available, depends on the specification required by the buyer) |

| Hydraulic Group Power | 3KW |

| Material of Cutting Blade | Cr12, hear treatment |

| Electric Standard | 380V /50Hz/3PH or as per customer's requirements |

| Machine Dimensions | 9430mm×1960mm×1650mm |

| Major Color of Machine Painted | RAL 5015 (Blue) or as per customer's requirements |

CANGZHOU ZhongHeng Machine Manufacture Co.,ltd is a professional manufacturer and exporter which has its own factory and also cooperate with several production factories and associated enterprises, concerning with the design, development and production of cold roll forming machines,material of building. It is located in northwest of CangZhou, as a long history of cold roll forming machine production base. All products comply with international quality standards and are greatly appreciated in variety of different markets throughout the world, Our company is organized and run as a modern enterprise system. We specialize in the automated production line of sheet cold roll forming machines. We are able to provide an integral resolution schema of cold roll forming system through a combination of advanced system design and equipment. Based on our advanced research and commercial team, we are able to research and development, manufacturing and sale of standard and non-standard cold roll forming equipment for our clients world widely.

We would like to invite you to come and join our to build our mutual benefit.