ZhongHeng Machine Manufacture Co.,Ltd |

|

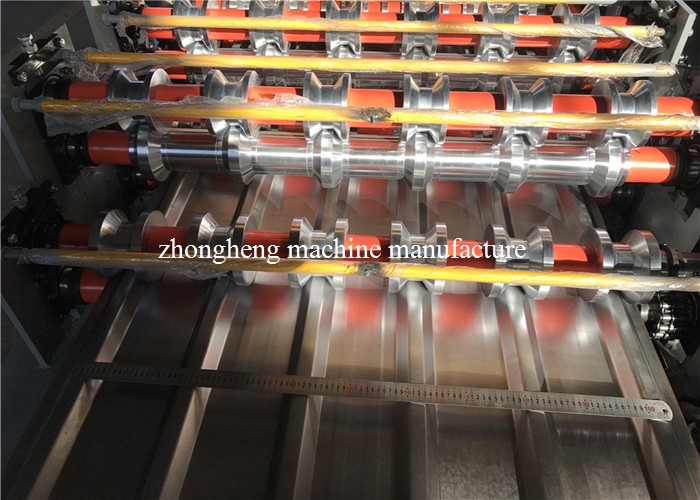

Double Layer Corrugated Sheet Roll Forming Machine With Hydraulic Station

1.Machine pictures

2.Description:

Double roofing ,corrugated sheet and trapezoidal type is the most popular model of roofing,its widely used in roofing and wall of the workshop.

There is two cylindas on the cutting head of this machine,the hydraulic oil is running into the cylinda,control the cutter easily.

3.Specifications

| Roller steps | 16 upper layer/16 bottom layer |

| Dimension | 7200*1600*1550mm |

| Weight | 7.5t |

| Feeding width | 1200mm |

| Forming thickness | 0.35-1mm |

| Large frame | 400mm H-Beam |

| Diameter of roller | Φ80mm |

| Middle plate | 16-25mm |

| Chain Size | 1 inch |

| Voltage | 380V 50HZ 3 phases or customized |

| Motor power | 7.5kw |

| Pump station power | 5.5kw/(7.5kw hydraulic motor) |

| Transducer power | 7.5kw |

| Cutting system | Hydraulic cutting(avoiding noise and smooth cut) |

| Material of cutting | Cr12 |

| Control system | PLC brand :Panasonic |

| Length error : ±2mm | |

| Production capacity | 10-15m/min |

| Warranty | 1 year and we provide technical support for whole life, and overseas service |

| Maintain | Easily :Timely adding oil |

| Payment terms | 30% in advance, the balance before delivery |

| Package | Standard package |

| Delivery | 35 days after receiving the deposit |

4.Components Details

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 350# steel. More stable and no shaking. |

| Middle Plate | 16mm. We use thicker plates to ensure stability of our products. |

| Forming Steps | 16, according to the drawing. |

| Shaft Material | Φ70 mm, high grade 45# steel. |

Treating process: tempering- finish turning, high rigidity, hard to deform. | |

Cutting Blade Material | Cr12, hardness HRC60-62. |

| Treating process: heat treatment- plane abrasion- wire electrode cutting. |

5.Electric Components

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 7 inch touch screen, easy to operate. |

| PLC | Delta DVP14ES |

Well-adapted to various conditions, such as moisture, electromagnetic disturbance. | |

| Frequency Converter | Delta VFD-M. It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

Length Measurement Device | Omron, made in Japan. |

| It features with high accuracy and stability. |

6.Detail picture

A Rollers with chorm

B 75mm solid shaft

C 1mm thickness material testing

D Cutting device

E precutter

F Full sight

More Information please contact Rebecca freely

WhatsApp&Wechat : +86 15720370230

| Website | www.roofsheetrollformingmachine.com |

| Youtube | www.youtube.com/channel/UCFbWECOfV2xeM-WCaww_iPQ |

| www.facebook.com/Rebeccamachinery |