ZhongHeng Machine Manufacture Co.,Ltd |

|

1.Competitive Advantage:

1.

Light,good strength,cauterization resistance and water resistance;

2.

Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3. Save Space,two profiles made in one machine .

4. Easy and fast for installation,time-saving;

5.

prompt delivery,high quality,competitive price and complete sets of style;

6.

We can supply you the products based on your specific requirements;

2,Applications:

This kind of channel used for Window

section

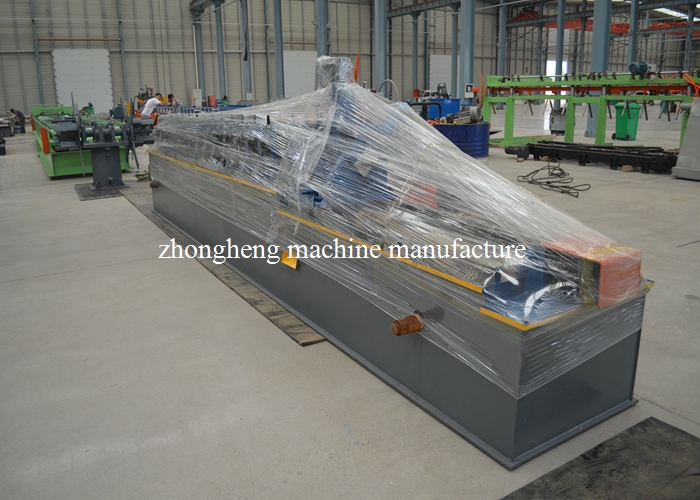

3.Description:

This machine is produce the L angle profile,its the edge

of the profile assistant for the U and C stud when stallation.

4.Specifications

1. | Power | Type | 380v/3ph/50hz |

|

|

| Main Motor power | 5.5kw |

|

|

| Cutter power | 4kw |

|

2. | Forming speed(m/min) | 25m/min max | Not include the time of cutting | |

3. | Forming stations | 10stations |

| |

5. | Material of rollers | CR12 |

| |

6. | Thickness of structure | 30mm |

| |

7 | Forming shaft diameter(mm) | 40 |

| |

8 | Drive | Gear |

| |

9 | Type of cutting | Hydraulic cutting |

| |

10. | Control system | PLC taida |

| |

11. | Install dimension(depend on the final design) | 3.8m×0.6m×1.2m | Without panel length | |

12. | Total weight (Approx) | 2.3T | Depend on final design | |

13. | Screen | Text screen /touch screen |

| |

6.Components

1.Manual Decoiler part

Usage:It is used to support the steel coil and uncoil it in a

turnable way.

Passive uncoil pulled by roll forming system

2. Coil feeding part

Usage:Put the raw material(steel plate) through the beach to

manufacture and process,

it can guarantee that the products are neat, parallel and

everything is uniformity.

Please refer to the equipment regulation to know the function of

locate angle iron.

3.Main roll forming machine part

Usage: In order to keep the product shape and precision, adopts

welded sheet structure, motor

reducer drive, chain transmission,roller was chromed which can keep

the molding plate surface

smooth and not easy to be marked when it is working

4.Automatic cuttting system part

It adopts the hydraulic drive and automatic encoder to cut the

accurate length you set on the computer.The tolerance is within

10m±1mm

Material of blades: Cr12 quenched

Power supply : hydraulic power

Components:It contains one set of blade, one hydraulic tank and one

cutter machine

5.Computer controlling part

1).PLC brand: Normally, it is Delta. Mistubishi, Panasonic, Siemens

are optional.

2).working model: fully automatic and manaul

3).working language: normally are English, Chinese,Russia. Can be

set as per your requirements.

6. Hydraulic station

1).including one motor,one oil tank,one magnetic valve,one pressure

gage, hydraulic oil tube

2).3kw,4kw,5.5kw,will be adopted as per your profile sheet.

contact information