ZhongHeng Machine Manufacture Co.,Ltd |

|

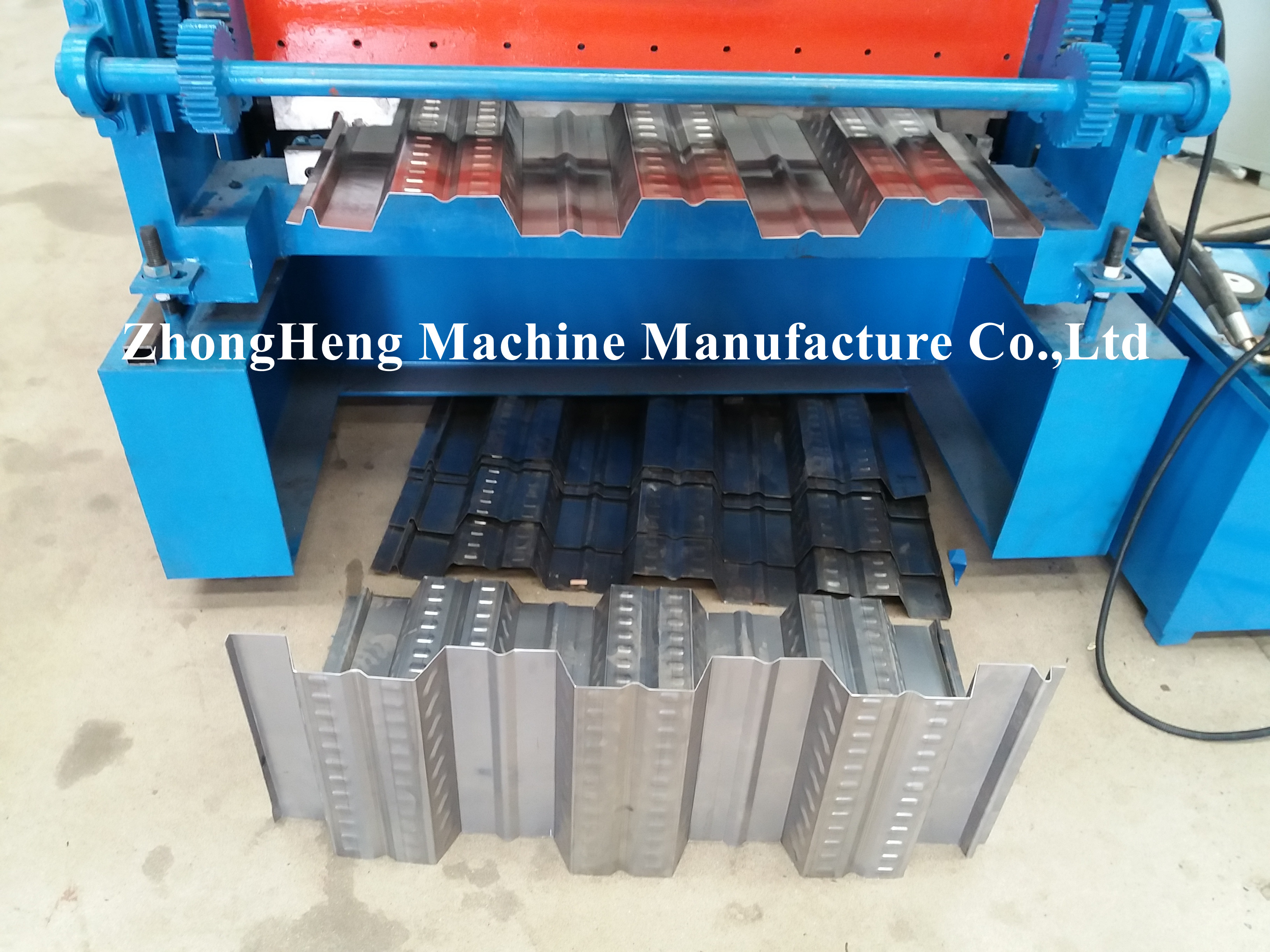

Galvanized steel Metal Floor Deck Roll Forming Machine 220V 60HZ 3 phases

Technical Data of Deck Floor Machine

1. Steel Sheet Thickness: 0.75-1.2mm (depend on requirement )

2. Transmission way: single chain

3. Transmission material: 45# steel, high frequency quenching

4. Material of blad: Cr12, quenching treatment

5. Capacity of Decoiler: 5 ton passive decoiler

6. Forming Speed: 8-12m/min

7. Roller Groups: 28 stations

8. Roller Material: 45# steel, high frequency quenching treatment,

HRC58-62

9. Feeding material: galvanized steel

10. Principal Axis: 45#steel with quenching treatment

11. Main motor power: 18.5 Kw

12. Hydraulic power: 7.5Kw

Deck Floor Machine Main Components

| S.N | Equipment name | Quantity |

| 1. | 5T passive un-coiler | 1 set |

| 2. | Feeding and leveling device | 1 set |

| 3. | Main roll forming machine | 1 set |

| 4. | Hydraulic cutting | 1 set |

| 5. | PLC Control system (including control box) | 1 set |

| 6. | Out tables | 2 sets |

Advantage for Deck Floor Machine

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

Specifications

NO. | ITEM | PARAMETER | NOTE | |

1. | Suitable | Type | Galvanized sheet |

|

|

| Width(mm) | 1250mm |

|

|

| Thickness(mm) | 0.5-1mm |

|

|

| Yield stress(mm) | G220-G300 |

|

2. | Product | Detail as the attached file | ||

|

| Length | Any length |

|

3. | Power | Type | 220v/380v/3ph/50hz |

|

|

| Main Motor power | 11kw+11KW |

|

|

| Cutter power | 5.5kw |

|

4. | Forming speed(m/min) | 8-15 | Not include the time of cutting | |

5. | Manual Decoiler | Type | Manual |

|

|

| Max capacity | 5t |

|

|

| Suitable coil OD(MM) | 1000 |

|

|

| Suitable coil | 508 |

|

6. | Forming stand | 27 | Depend on actual design | |

7. | Thickness of structure | 20mm A3 steel plate |

| |

8. | Forming shaft diameter(mm) | 85 #45 steel |

| |

9. | Type of cutting | Roll formed and |

| |

10. | Control system | PLC and inverter | Panasonic brand | |

11. | Install dimension(depend on the final design) | 13.2m×1.5m×1.55m | Without panel length | |

12. | Total weight (Approx) | 10T | Depend on final design | |

Description:

A.

We will arrange engineers to supervise installation and make adjustment for the equipment; Buyer should

pay

$50 for each engineer every day. The buyer should be responsible for transportation (

including round-trip

ticket), insurance, accommodation.

B. Guarantee period:

1.

The warranty will be maintenance, maintain in the guarantee period of one year starting from delivery.

Because of the quality of equipment during guarantee period, we will provide the parts free of charges,

which is

in the conditions of correct operation. (Natural disasters or factors which can’t forced by human are

excluded).

2.

If the equipment are out of work in the guarantee period, the buyer needs our repairman to come to

buyer’s

factory, the buyer should be responsible for the tickets(including round-trip ticket), the fee of transportation

to

the buyer’s factory and the fee of accommodation. Required to change spare parts, the buyer should

afford

the freight fee and we don’t ask extra fee.

C. Detail Engineering

1. Lay out and general arrangement drawing

2. Funation lay out drawing

3. eration and maintenance instructions

D. Training

During installation and adjustment of the equipment, our engineers shall provide the training to buyer’s

personnel to operate and maintain the equipment. Additional trading can be provided on request.

1.

Foundation construction, electrical works, and civil engineering;

2.

Electrical wire, mechanical tubes, water tubes between machines;

3.

Lubricating oil, recirculation oil, gear box oil, recirculation cooling water;

4.

Safety equipments and non-standard safety items;

5. Testing material;

6.

Engineering service required at the buyer’s site.

Applications:

Floor deck is a lightweight decking system, for car pack construction, comprising steel profile, top-

reinforced

by concrete. Floor deck roll forming machine is the essential manufacturer of its production.