ZhongHeng Machine Manufacture Co.,Ltd |

|

Galvanized Corrugated Roofing Panel / Roof Sheet Making Machine PLC Control

1. Description:

This model of machine is for nigeria market,the tile is popular in nigeria.Raw material is PPGL,Aluminum is light and can get more length from a coil.

2. Competitive Advantage:

1. save space

2. easy installation

3. perfect service

4. excellent quality

5. Operate easily

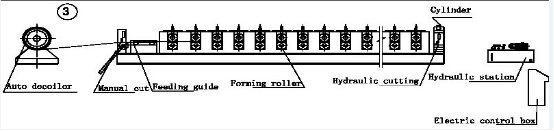

3. Flow chart

4. Specification

| NO. | ITEM | PARAMETER | NOTE | ||

1.

| Suitable material

| Type | Pre-painted sheet, Galvanized sheet Galvanized Aluminum | ||

| Width(mm) | 1200mm | ||||

| Thickness(mm) | 0.3-0.8mm | ||||

| Yield stress(mm) | Q235 | ||||

| 2. | Product specifications | Detail as the attached file | |||

| Length | Any length | ||||

| 3. | Power requirement

| Type | 380v/3ph/50hz | Motor brand shanghai Lichao | |

| Main Motor power | 4kw+4kw | ||||

| 4 | Forming speed(m/min) | 2-10m/min | Not include the time of cutting | ||

| 5. | Manual Decoiler

(Optional) | Type | Manual | ||

| Max capacity | 5t | ||||

| Suitable coil OD(MM) | 1200 | ||||

Suitable coil ID(MM) | 508 | ||||

| 6. | Forming stand | 16 | Depend on actual design | ||

| 7. | Thickness of structure | 16mm | |||

| 8. | Forming shaft diameter(mm) | 70 solid | |||

| 9. | Type of cutting | Roll formed and length-set cutting | |||

| 10. | Control system | Panasonic PLC and inverter | |||

| 11. | Install dimension(depend on the final design) | 8.3m×1.5m×1.2m | Without panel length | ||

| 12. | Total weight (Approx) | 4T | Depend on final design | ||

5. Applications:

| Our machine | Other company 's machine | Influence of the machine | |

| Machine's base | High strength H350 / H400 steel. machine through milling macine after welding | H270 steel mark, after welding use manual polish | keep base in the same horizontal line, ensure product standard |

| Roller material | High grade No.45 forged steel, with digital-controlled procession, Plated with 5 um chrome coated | Normal No. 20 steel with Simple polished and have no coating | Roller will have longer use life and ensure the products have same size,no nick on the surface. |

| Side wall | Use high strength16mm thickness steel panel mark | Use 12 mm thickness steel panel mark | Ensure machine harder to deform, keep the product accurate and stable |

| Active shaft material | High grade solid No.45 carbon steel, Shaft diameter is 70mm. surface CNC polish treatmen | Normal No. 45 steel with no surface treatment | Improve the integrated mechanic feature of the shaft. and ensure the shaft stability keep product standard |

| Electrical elements | PLC control panel, transducer imported from Panasonic of Japan. Other elements from famous suppliers in China | All the elements are made in china | Machine become more accurate and more stable |

| Cutter blade | Cr12 mould steel with quenched treatment | Normal high strength steel without quenched treatment | Stable the integrated mechanic feature of the cutter blade,harder to deform, longer blade's life, ensure product standard |

Machine picture