Shanghai LIVIC Filtration System Co., Ltd. |

|

Verified Suppliers

|

|

Latex Scraping Self Cleaning Filter, Mechanically Cleaned Bentonite Filtration

Description

Latex scraping self-cleaning filter ( DFA FILTER for short), is the

new high performance scraping self-cleaning filter independantly

developed by LIVIC. It automatically removes the particles and

impurities from the filter element internal surface by mechanical

scraping and it can continuously work on-line. DFA is designed for

filtration of high viscosity up to 800,000mPa.s. The filtration

degree ranges from 50~1500μm. It can scrape the impurities off the

filter element surface most quickly, which makes it more

efficiently removing the impurities. It is applicable for water and

various viscous liquid. The DFA filter is designed and manufactured

by following LIVIC's high performance, high quality and high

reliability standard. It is a world-class quality filter.

The conventional filters get clogged frequently when filtering the viscous liquid and removing the soft impurities. The customers have to select larger filters or clean the filter manually and freqeuntly, which means expensive investment, hard work, valuable liquid loss. DFA filter solves these kinds of problems by its advanced self-cleaning principle. It always keeps the filter element clean, discharges waste liquid with high impurity concentration, reduces the liquid loss. When filtering the viscous liquids such as dirty water, adhesives, resins, polymers and oils, DFA filter works more efficiently. DFA filter is taking place of the vibrating screen, bag filter, basket filter and some kind of back-flushing filter by its technical advantages and low running cost.

For DFA filter, LIVIC has developed about 20 specific ACS control

system models, which are categorized into basic and advanced

version. They are based on Simens LOGO!, run LIVIC's programs,

efficiently control the filter and meet various automatic control

requirements.

Basic version is the time control type. The cleaning cycle and the

purging cycle are set by time cycle. No differential pressure

instrument.

Advanced version has both differential pressure(D.P. for short) and time cleaning modes. The D.P. indicates the filter cake accumulation and the filter element clogging. When it reaches the preset D.P. value under D.P. mode, the cleaning sequences are triggered. The recommended D.P. value is 50KPa, which can be adjusted between 10 and 100KPa. The D.P. mode is the most efficient and widely applicable. The time mode can be set between 0 and 24 hours. If the D.P. mode fails, the time mode still works as the final safety protection. The preset time shall be close to the average cycle under the D.P. mode.

Advanced version reserves three dry contact points, which indicate

the power status, cleaning status and failure feedback. The failure

feedback includes the over-load D.P., valve action failure, scraper

stucking. It monitors the filter, feedback the failure in time,

prevent the equipment damage and prevent the liquid waste and

pressure fluctuation in time because of the valve failure.

Two types of D.P. instruments available: one D.P. transmitter or

two pressure transmitter as the combination measurement. The

transmitter is sensitive and reliable and outputs the real time

D.P..

The specified ex-proof class design is available. All instruments

and control panel meet the ex-proof requirements. The control

system based on the Simens S7-200 PLC is also available, can be

configured into DCS and supports Profibus-DP or Modbus

communication protocals.

Specifications:

| Filter Main Type | DFA7 | DFA22 | DFA41 | DFA71 | DFA213 | DFA284 |

| Filter Area(㎡) | 0.07 | 0.22 | 0.41 | 0.71 | 2.13 | 2.84 |

| Filter Element Qty. | 1 | 3 | 4 | |||

| Volume(L) | ~4 | ~24 | ~42 | ~175 | ~620 | ~760 |

| Inlet&Outlet Size | DN25-DN50 | DN50-DN80 | DN65-DN100 | DN80-DN125 | DN100-DN150 | DN150-DN250 |

| Purge Size | DN40 | |||||

| Applicable Liquid | water and viscous liquid (<800000cps),impurities content<1000ppm | |||||

| Filtration Degree | 50-2000μm | |||||

| Standard Design Pressure | 1.0MPa,higher design pressure available | |||||

| Design Temperature | 0-200℃(determined by seal materials) | |||||

| Cleaning D.P. | 50-100KPa(differs by the liquid viscosity) | |||||

| D.P. Instrument | pressure transmitter / differential pressure transmitter | |||||

| Inlet&Outlet Standard | HG20592-2009 Flange(standard, DIN compatible ), HG20615-2009 Flange ( ANSI B16.5 compatible)DIN11851 sanitary coupling, female thread | |||||

| Filter Element Series | MS/NS/AS | |||||

| Housing Wet Part Material | 304/316L/CS | |||||

| Piston Material | 316L | |||||

| Scraper Material | PTFE | |||||

| Housing Seal Material | NBR/EPDM/VITON/Silastic/FEP encapsulated Silastic | |||||

| Element Seal Material | NBR/EPDM/VITON/Silastic/FEP encapsulated Silastic | |||||

| Piston Rod Seal Material | NBR/PU/VITON | |||||

| Purging Valve | Full-port pneumatic ball valve, single action or double action, material 304/316 | |||||

| Facility Supply Requirement | 220V AC for control system, 0.4-0.6MPa clean and dry compressed air | |||||

| Custom-made Design | jacket design for thermal oil or steam, keep the temperature and

fluidity ing the instruments and control system, for flammable and explosive

applications

| |||||

Applications:

■ Applicable Industries: petro-chemical, fine chemical, pulp and paper, food and beverage, water treatment, etc.

■ Applicable Liquid Types: wax, coal oil, monomer, polymer, citric acid, fermented broth, cosmetics, silicon solution, soap, sorbitol, steriodsugar, wet end additives, adhesives, inks, lubricating oils, coatings, resin, rubber, ethanol, miscella, edible oil, juice, diesel, etc.

TECHNICAL FEATURES AND ADVANTAGES

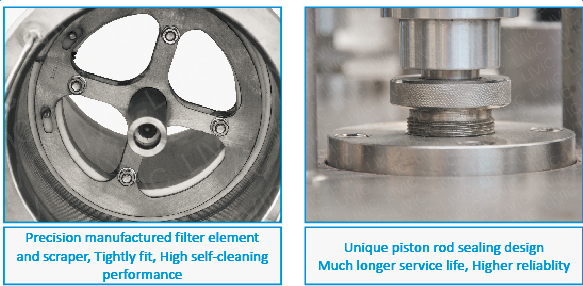

■Up-and-down reciprocating scraping, scrape impurities off

directly, especially good at viscous liquid filtration and removing

viscous suspending impurities

■Simple structure, easy disassembly, pull the filter element out

easily after removing the scraper, easy for internal cleaning

■Automatic operation, continuously on-line filtration, terminate

the hard work of filter element replacement and cleaning

■No disposable filter media, save the cost of filter media

consumption and the environment treatment

■Very low filtration pressure drop, steady flow rate, save the

energy, good for keeping the process continuous and steady

■Closed filtration, prevent danger of liquid leakage, good for

safety production and operator’s health