MOORE AUTOMATION LIMITED |

|

Verified Suppliers

|

|

1794-TB3S

The AB 1794-TB3S Flex I/O Terminal Base Unit has a 0.56-0.79 Nm Terminal Screw Torque, a 125V DC/AC, 50/60Hz, 10A Supply Voltage Range max., and a 125V Continuous Isolation Voltage. It also operates with a 0.34-3.3mm^3 Wire Size and a 94x94x69 mm Dimensions.

The 1794-TB3S Flex I/O Terminal Base Unit by AB is a 16 I/O

capacity terminal base unit module with eighteen common terminals

and eighteen voltage terminals used in applications with up to 125V

AC/DC rating. The module has a current of 10A (max) and provides a

Flexbus current of 640mA at 5V DC and a 2A current across the

input/output terminals. The 1794-TB3S also provides 125V AC/DC

voltage and 10A current at 50-60Hz across the voltage/COM

terminals. It can provide 125V isolation voltage between

Field-Wiring-to-FLEXBUS employing the Basic Insulation type and it

enables I/O termination using the spring clamp termination type.

The 1794-TB3S uses copper wire with 0.34 x 3.3mm2 stranded or solid

wire rated at 167 °F and with a 1.2 mm (3/64 in) thick insulation

as its base circuit cable and the module has a shipping dimension

of 94mm x 94mm x 69mm. Like most terminal base in the Flex I/O

series, it is given the T4A (North America) and T4 IEC temperature

code for maintaining function at a maximum temperature of 135 0C

and it has a factory-defined operational temperature limit between

-20 and 70 °C (-4 and 158 °F) at 5-95% non-condensing humidity. It

is IEC-tested to functionally resist an operational vibration of 2G

at 10-500Hz and it is also tested to operate without de-rating at a

shock of 30G. The 1794-TB3S is UL, CSA, CE, and Ex-certified.

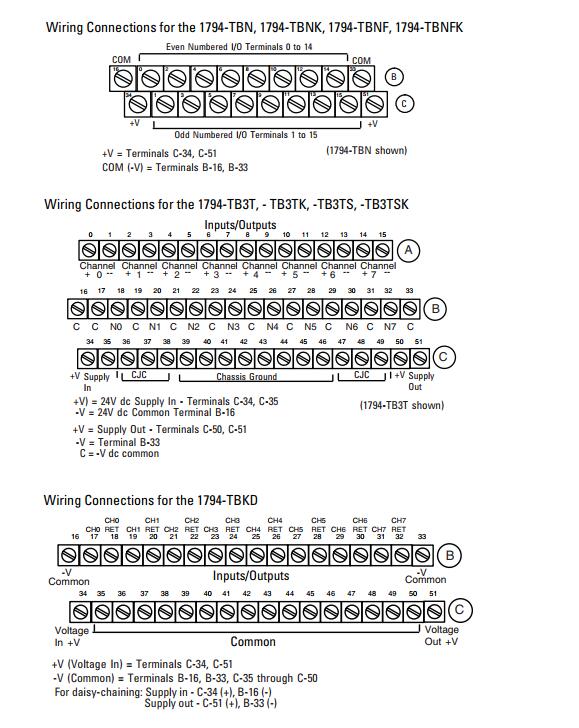

For Spring-clamp Terminal Base Units: 1794-TB3S, -TB3TS, -TB3GS, -TB32S, -TB3SK, -TB3TSK, -TB3GSK ″ Insert a 2.54…3.05 mm (0.10…0.12 in.) wide-bladed screwdriver into the slot and lift up. Insert wire, and remove screwdriver.For Cage-clamp Terminal Base Units: 1794-TB2, -TB3, -TB3K, -TB3T,-TB3TK, -TB3G, -TB3GK, -TB32 ″ Tighten screws to 0.8 Nm (7 lb-in). For Knifeswitch Cage-clamp Terminal Base Unit: 1794-TBKD ″ Tighten screws to 0.53 Nm (6 lb-in). For NEMA Screw-clamp Terminal Base Units: 1794-TBN, -TBNK, -TBNF, -TBNFK ″ Tighten screws to 1.02 Nm (9 lb-in). Install or Change a Fuse in the 1794-TBNF or 1794-TBNFK Terminal Base Unit This terminal base unit has fuse holders for 5x20 mm fuses on each of the eight even-numbered I/O terminals (0 through 14 - row B). To install or change a fuse: 1. Press the fuse holder down toward the terminal strip. 2. Remove the fuse from the fuse holder. 3. Insert a known good 5x20 mm fuse into the fuse holder. 4. Rotate the fuse holder back to vertical until it snaps into the locked position. The 1794-TBNF and 1794-TBNFK terminal base units are shipped with eight 5x20 mm, 1.6 A, 250V AC slow-blow fuses, one for each even-numbered terminal (0 through 14 on row B). These fuses are suitable for use with the 1794-OA8 AC output module. Refer to the specific installation instructions for fusing recommendations for your particular module. Use the Knifeswitch Terminal Base The knifeswitch terminal base has 16 individual mechanical-knifeswitch circuit breakers (two for each channel). Each switch opens or closes one side (input/output and return) for a channel

1. Place a small-bladed screwdriver into the slot of the knifeswitch of the I/O point circuit that you wish to break. 2. Rotate downward to open the circuit. This opens the path of an individual circuit. 3. To reestablish the circuit, rotate the knifeswitch back into the terminal base unit until it snaps into place.

Miya(manager)

Email:miya@mvme.cn

Skype:miyazheng520

QQ :2851195450

Tel:0592-5087576

86-18020776792

Related Product

Our products are widely used in

1.CNC machinery metallurgy,

2.oil and gas,

3. petrochemical,

4. chemical,

5.paper printing,

6.textile printing and dyeing,

7.machinery,

8.electronics manufacturing,

9.automobile manufacturing,

10.tobacco,

11.plastic machinery,

12.electricity,

13 water, water treatment / environmental protection,

14.municipal engineering,

15.boiler Heating,

16.energy,

17.transmission and distribution.

If you have any question pls do not hesitate to contact us.We can

supply all kind of the automaiton parts,if you want to purchase

parts pls send the parts model to my mail, I will prompt reply you

asa I receive the mail.Hope anyone enquire from us.

Miya(manager)

Email:miya@mvme.cn

Skype:miyazheng520

QQ :2851195450

Tel:0592-5087576

86-18020776792