zhangjiagang aquatrin Machinery co.,ltd |

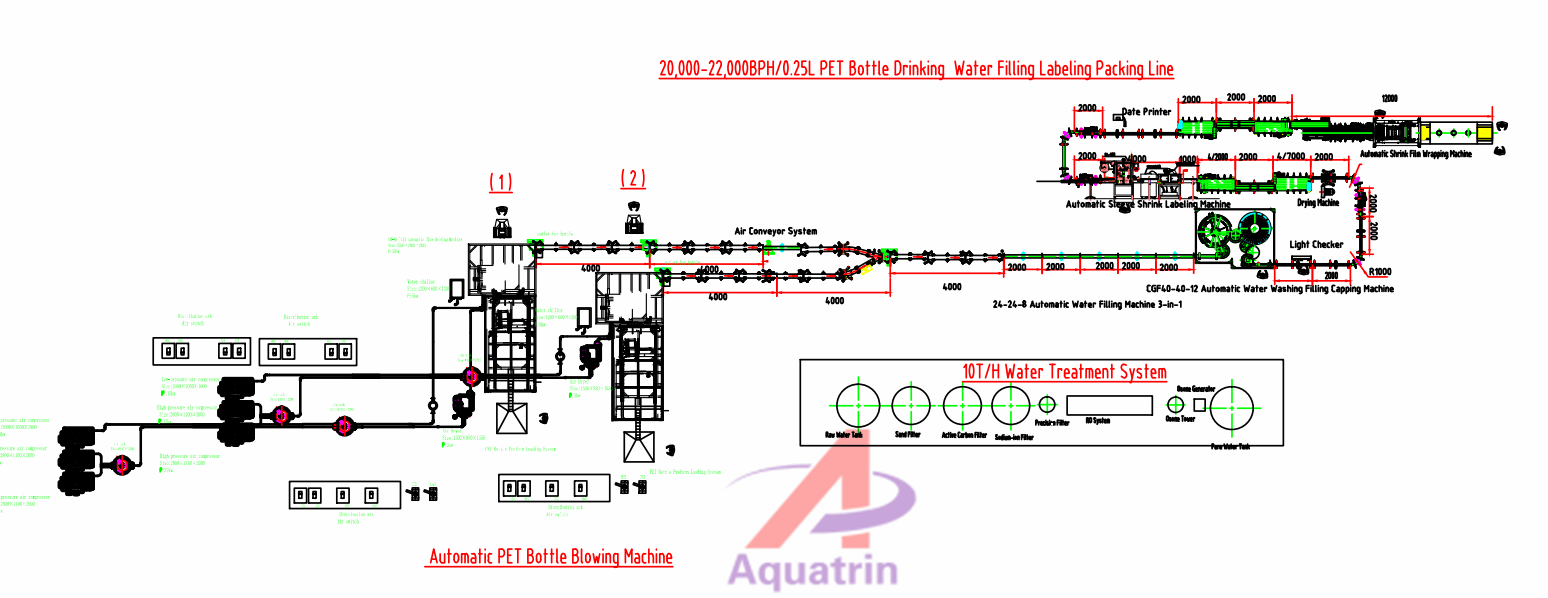

Model | Rated Capacity/BPH | Size/mm | Weight/T |

RCGF14-12-5 | 3000-4000 | 2180*1560*2300 | 3 |

RCGF18-18-6 | 5000-6000 | 2350*1900*2300 | 3.5 |

RCGF24-24-8 | 8000-10000 | 2900*2000*2300 | 5 |

RCGF32-32-10 | 12000-15000 | 3500*2850*2300 | 7 |

RCGF40-40-12 | 15000-18000 | 4500*3750*2300 | 10 |

RCGF50-50-12 | 18000-22000 | 5200*4000*2300 | 12 |

RCGF60-60-15 | 20000-25000 | 5500*4500*2300 | 15 |

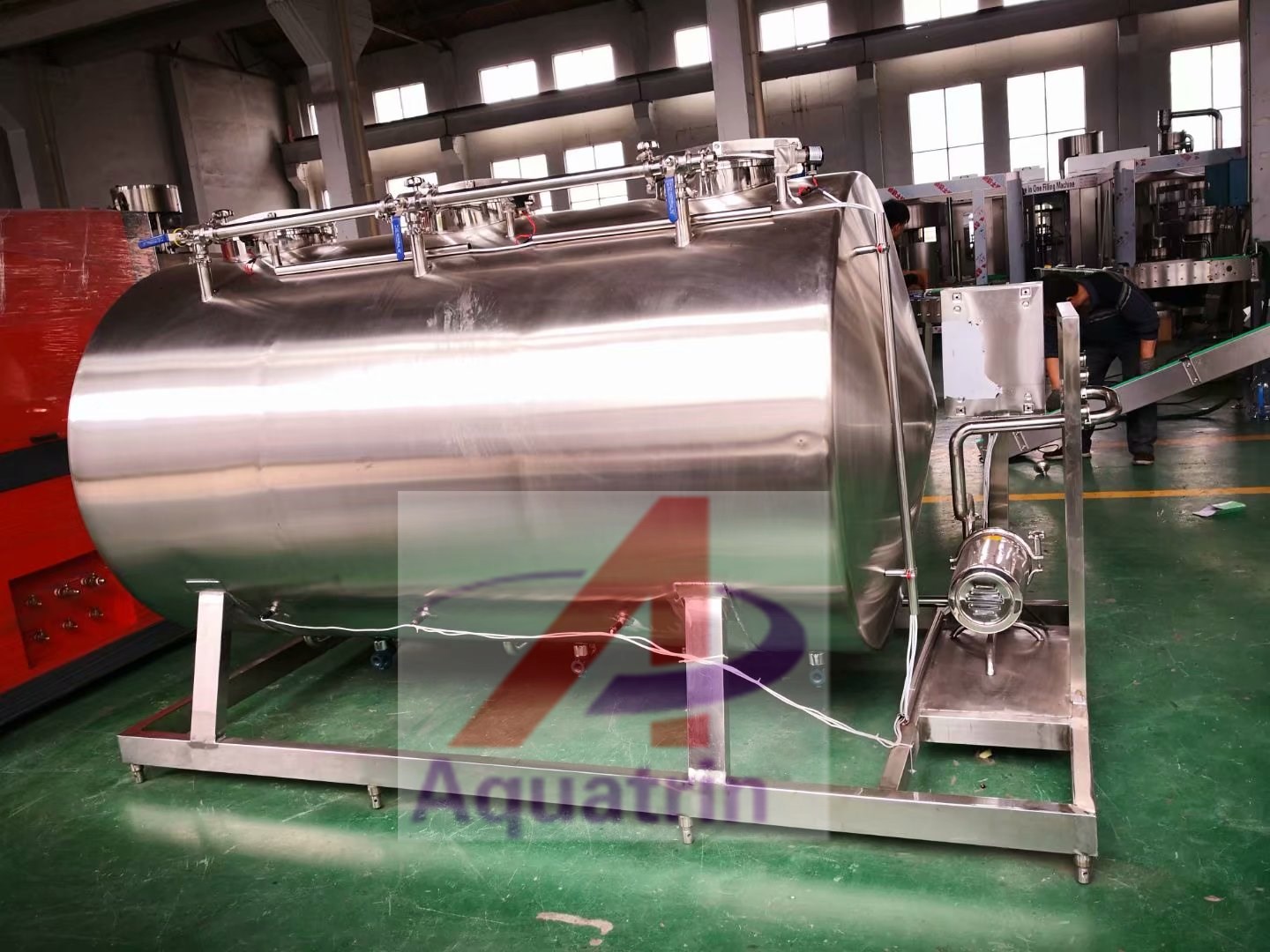

<1> The beverage processing system applies to beverage

processing for hot filling line and CSD filling line.

<2> product's scope hot water system, sugar dissolving system

( simple syrup system ), concentrate system, blending system (final

syrup system), CIP system, extraction system, kind of storage tank

/ valves / pipe / fittings, UHT system (plate / tubular type), and

carbo-cooler / mixer (manual / automatic)

The tube(pipe) sterilize machine can take hot process on the liquid foods and beverage.

It is mainly used in sterilizing PET bottle mouth and inside surface of caps. in which haven't been disinfected by themal tea,fruit juice which having been filed in PET bottle.

CIP plays role of rinsing syrup melting system, extracting and dispensing system for juice, homogenizer, and air exhauster. UHT sterilization system is attached with the CIP.

We suplly Free Factory Layout design

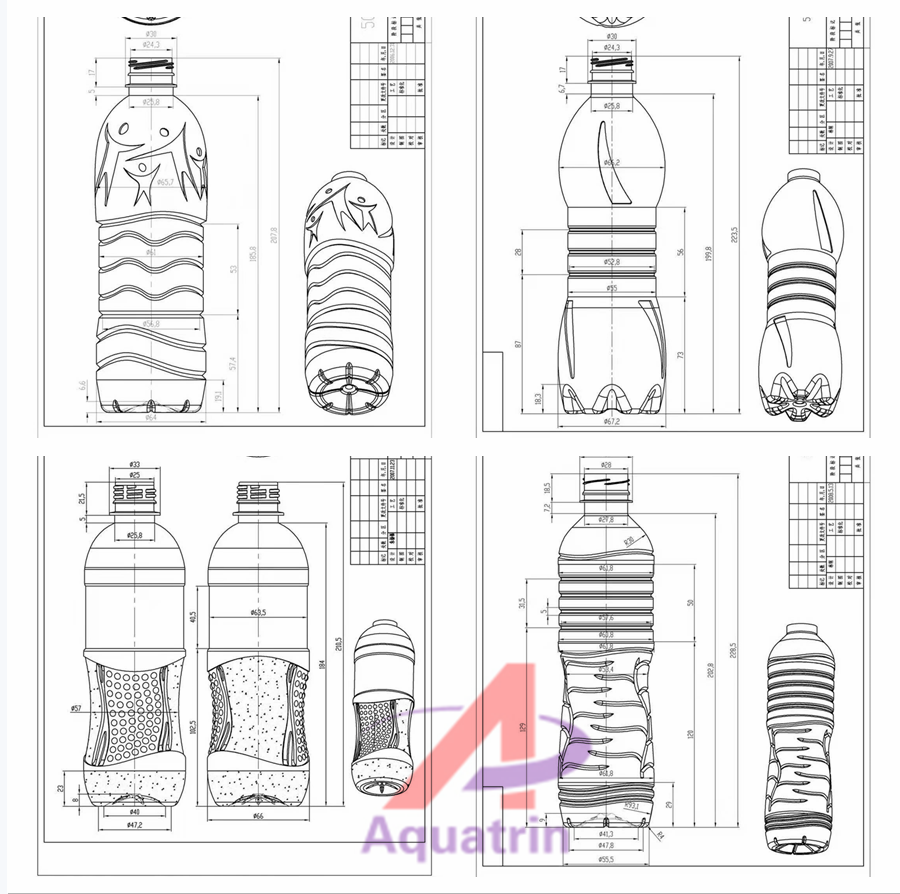

We suplly Free Bottle Shape design

Water treatment system

Labeling Machine

Laser date printer

PE film wrapping package machine

![]()