zhangjiagang aquatrin Machinery co.,ltd |

|

Type | Washing Nos | Filling Nos | Capping Nos | Capacity |

DXGF 8-8-3 | 8 | 8 | 3 | 2000BPH |

DXGF 14-12-5 | 14 | 14 | 5 | 5500BPH |

DXGF 16-16-5 | 16 | 16 | 5 | 8000BPH |

DXGF 24-24-8 | 24 | 24 | 8 | 12000BPH |

DXGF 32-32-8 | 32 | 32 | 8 | 15000BPH |

DXGF 40-40-10 | 40 | 40 | 10 | 18000BPH |

DXGF 50-50-15 | 50 | 50 | 15 | 24000BPH |

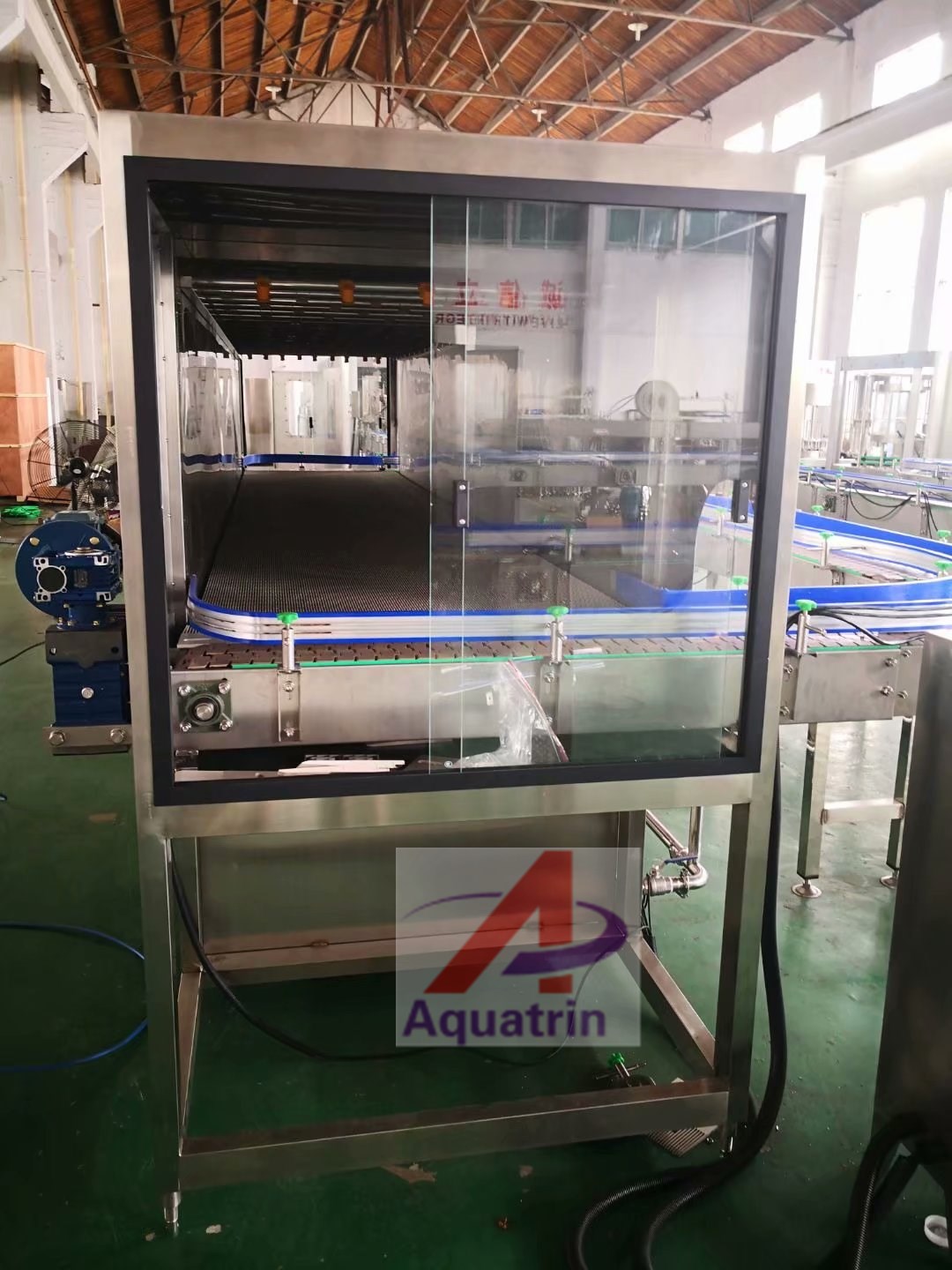

Washing Part

All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and clean

Filling Part

Capping Machine

S/N | Name | Brand | country |

1 | Main motor | ABB | Switzerland |

2 | Inverter | MITSUBISHI | Japan |

3 | PLC | OMRON | Japan |

4 | Touch screen | MITSUBISHI | Japan |

5 | Contactor | SCHNEIDER | France |

6 | Thermo- relay | SCHNEIDER | France |

7 | Air-break switch | SCHNEIDER | France |

8 | Proximity switch | TURCK | USA |

9 | Photoelectric switch | BANNER | USA |

10 | Air circuit system | SMC | Japan |

11 | Water pump | Southern | China |

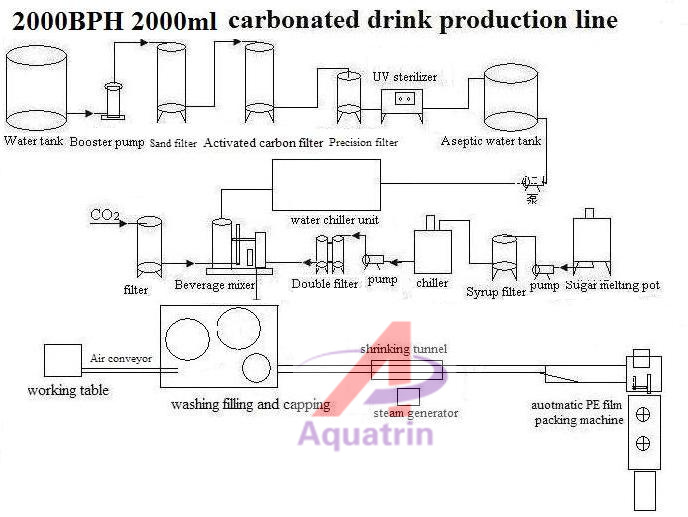

carbonated drink process layout