Washing heads.

1.Stainless steel 304/316L washing heads.

2.Using unique design,avoid the traditional bottle on rubber clip to block the bottle

threaded parts may be caused by the pollution.

3.Washing pump is made of stainless steel.

4. By high spray nozzle, blunt bottle of water jet angles, flush to the bottle of any part of the inner wall, rinse with

water thoroughly and save flush bottle.

Filling heads.

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level

after filling

<3> All 304/316 stainless steel contact parts & liquid

tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

<5>Efficient spray nozzle rinse thoroughly and save water for

flushing

Capping heads.

<1> Place and capping system, electromagnetic capping heads,

with burden discharge function, make sure minimum bottle crash

during capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

<5>Capping effect is stable and reliable ,Defective rate

≤0.2% .

Carbonated Drink Process

We also supply the complete Filling package line

Water treatment systemThe Reverse Osmosis process uses a semi-permeable membrane to

separate and remove dissolved solids, organics, pyrogens, submicron

collodial matter, viruses, and bacteria from water. The process is

called "Reverse" Osmosis since it requires pressure to force pure

water across a membrane, leaving the impurities behind. Reverse

Osmosis is capable of removing 95 - 99% of the total dissolved

solids (TDS) and 99% of all bacteria, thus providing safe, pure

water.

Carbonated drink blending system It can improve the proportion of water, syrup and carbon dioxide.

It is used in carbonated beverage production line and sparking

wine. It is used to cooling the water before mixing which is

connected with the mixer.

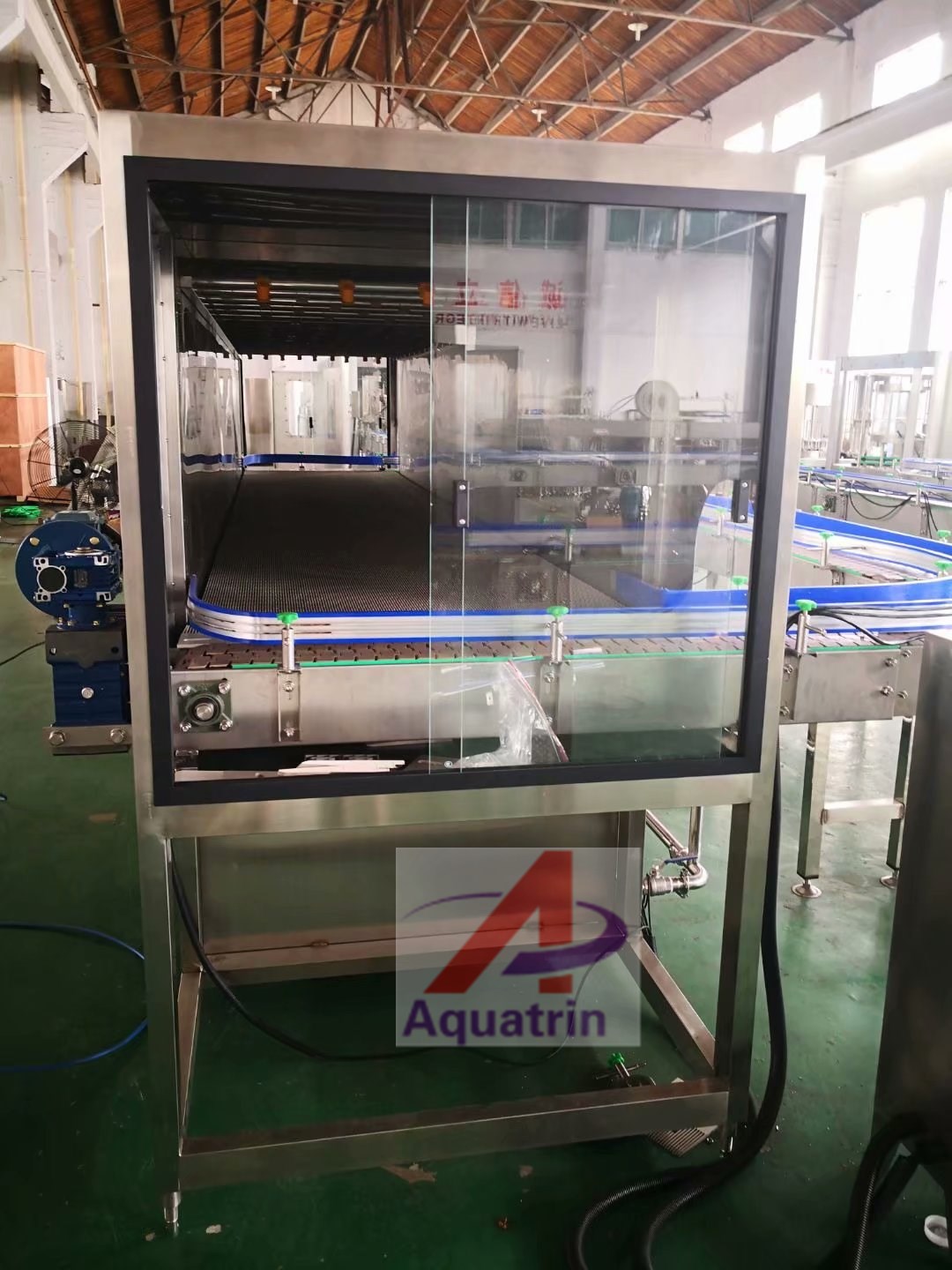

Cooling tunnel

Beverage Mixer

Chiller

Our customers

Shipment