Beijing Silk Road Enterprise Management Services Co.,LTD |

|

Verified Suppliers

|

|

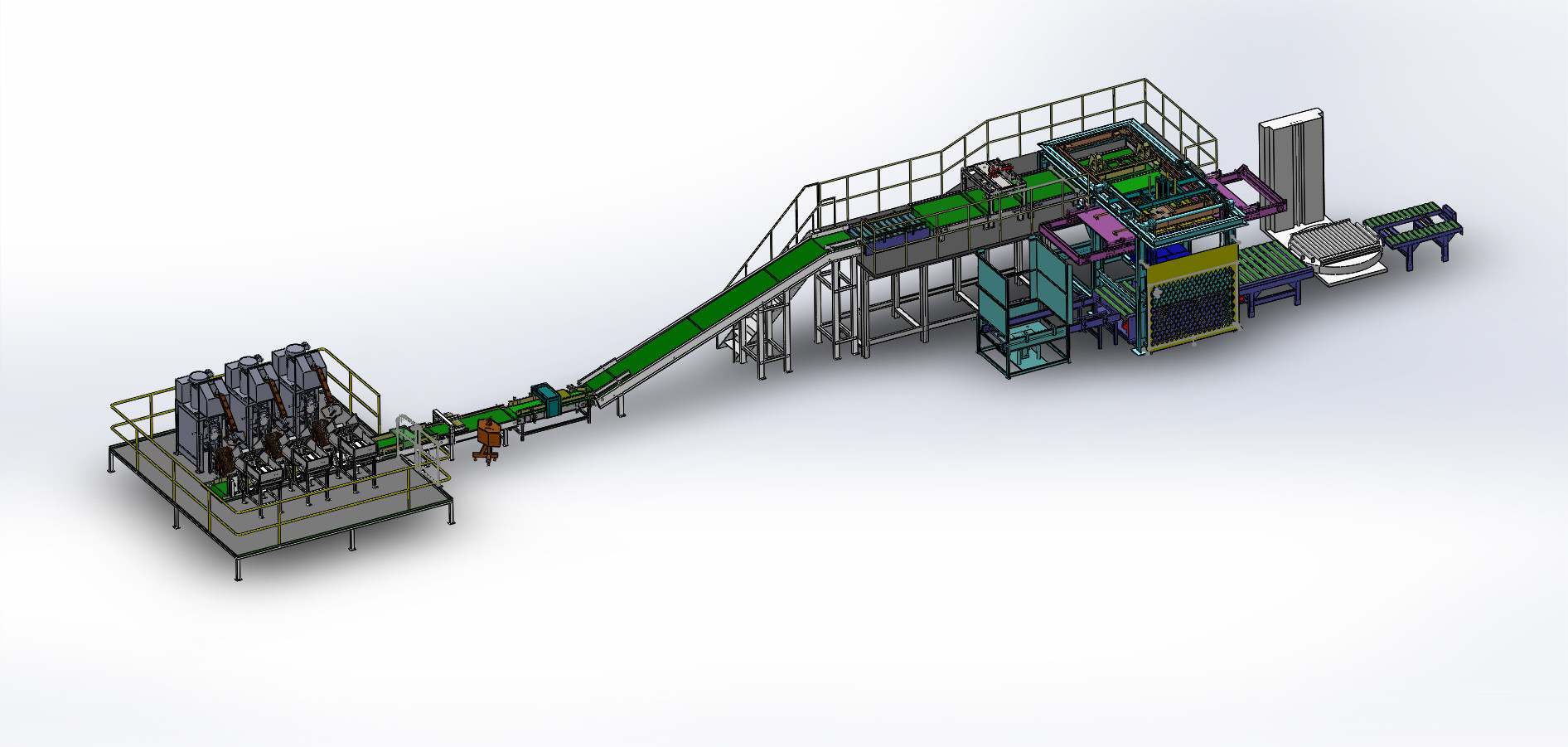

High Position Palletizer for Stacking FMCG Products Food Beverage on Pallets

I. Working Principle

1. Product Introduction

High - level palletizing machine is a special high speed automatic palletizing machine. Hongsen Intelligent high level palletizing machine HS-GW-1500 could lift bag to a certain height, then transfer, marshall, layer and stow the material bag according to the predetermined way on the empty pallet with layer type, and finally output with the finished pallets.

2. Features

The high - level palletizing machine is to carry out each layer according to the bag counting. The material bag is changed by the transposition machine to reach the preset pallet type. The marshalling machine determines which bags are in which layer, and then the bag pusher accurately push the bag onto the pallet. After it finished the palletizing, the loading car will put the full pallet on the conveyor, waiting for the forklift to take away.

Ⅱ Features of this palletizing system:

1. Intelligent operation management;

2. Reduce the number of employees and the intensity of labor;

3. Widely used for automatic palletizing in petrochemical, food, medicine, fodder, grain, non-ferrous minerals and building materials industries.

4.Gripper doors open simultaneously. Bags are dropped on sliding doors. Boxes and crates are lowered on sliding doors by centralisation unit

5. Pallet is lifted up the enclosed stacking cage to be right

underneath the sliding doors where individual layers are formed

6. Once layer is complete, squeeze collar compresses it to create a

tight confined layer to the pallet's dimensions

7. Sliding doors open to place layer on the pallet

Ⅲ. Equipment Composition:

Slope Conveyor

Roller Conveyor

Servo Transposer

The Marshalling Machine

Push Bags System

Layering Device

Pallets Library

Pallet Conveyor

Block Conveyo

Ⅳ.Technical Parameters:

| Model | Material | Palletizing speed | Pallet size(mm) | Palletizing height(mm) | Power Supplier | Power consumption | Machine dimensions(mm) |

| HS-MD1000 | Carbon steel | 2-4 layers/min | L1000-1200* W1000-1200 | 200-1600 | 220/380V 50HZ | 6KW | L7300*W4100*H3500 |

Welcome to inquiry us for your end of line solution!!!