Beijing Silk Road Enterprise Management Services Co.,LTD |

|

Verified Suppliers

|

|

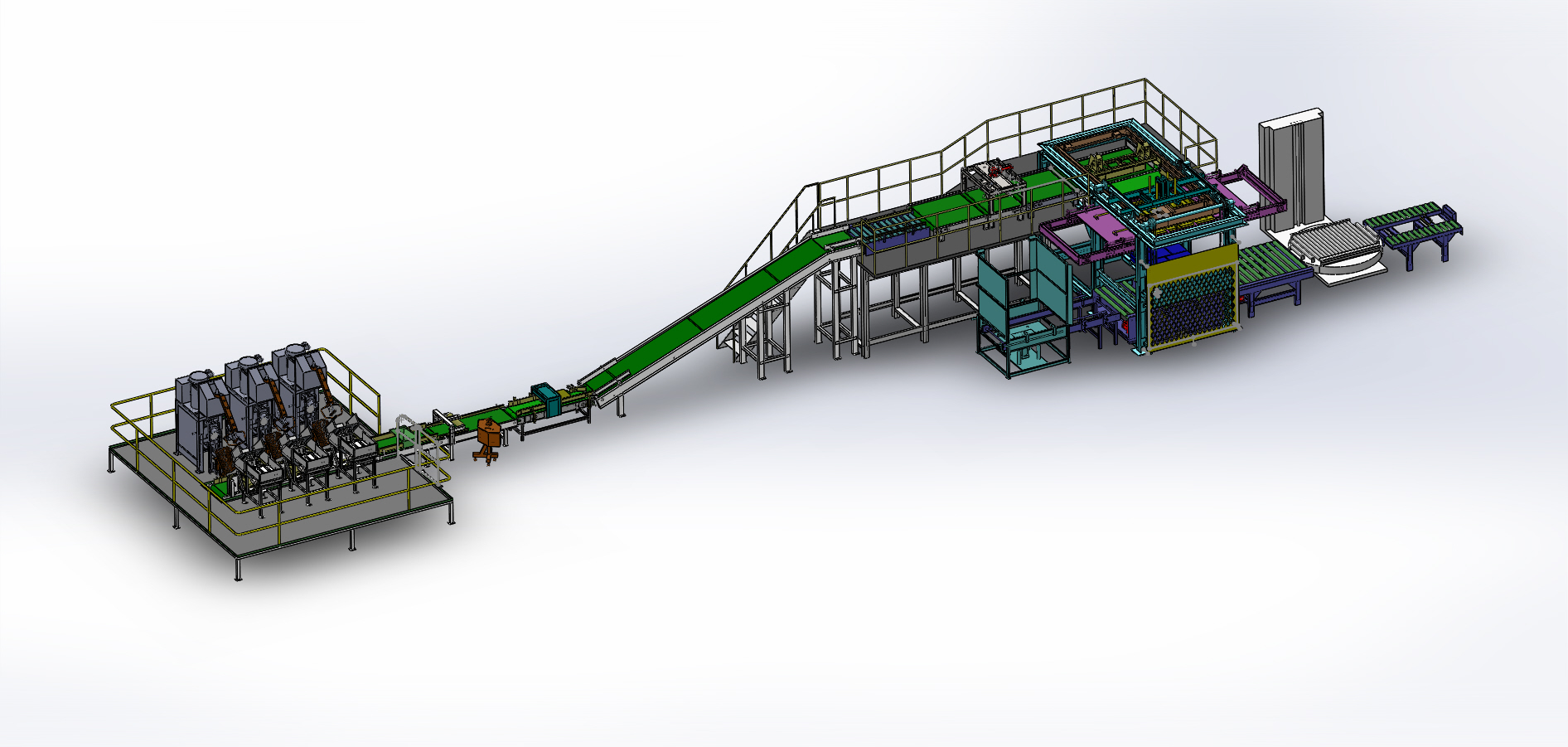

BB Compound Fertilizer Factory 25-50kg Packaging Equipment of Automatic Bag Packing Machine With Open Mouth Bag

Automatically complete bag-fetching, bag clamping, weighing, filling, and sealing, this open bag

filling and bagging machine is developed for the packing of a variety of powdery and granular materials in many industries including chemicals, agriculture, food, animal feed, cement, flour and so on.

Easy to operate and maintain and brand-name products are used for control and working parts.

Bag-feeding equipment is designed with advanced concept and the materials can be filled fully into bag. Filling-stop mechanism is installed for material filling with high accuracy/ Autoimatic sewing machine and heat-sealing machine optional.

1. Weight Range:10-25kg/ 25kg-50kg

2. Weight Rate: 200-600kg

3. Air Supply: 0.6-0.8 MPa

4. Weight Accuracy: ±0.2%

5. Voltage: 380V/ 50Hz

6. Working Environment: -15℃-45

| No. | Designation | Brand |

| 1 | Photoelectric switch | OMRON |

| 2 | Inductance proximity switch | OMRON |

| 3 | PLC and extension unit | OMRON |

| 4 | Push button | Schneider |

| 5 | Indicator light | Schneider |

| 6 | Selective switch | Schneider |

| 7 | Key switch | Schneider |

| 8 | Emergency stop switch | Schneider |

| 9 | Air switch | Schneider |

| 10 | Touch screen | HITECH |

| 11 | Servo motor | Yaskawa |

| 12 | Motor for lifter | SEW |

| 13 | Main bearings | SKF |