Ruian Best Machine Co.,Ltd. |

|

| Description |

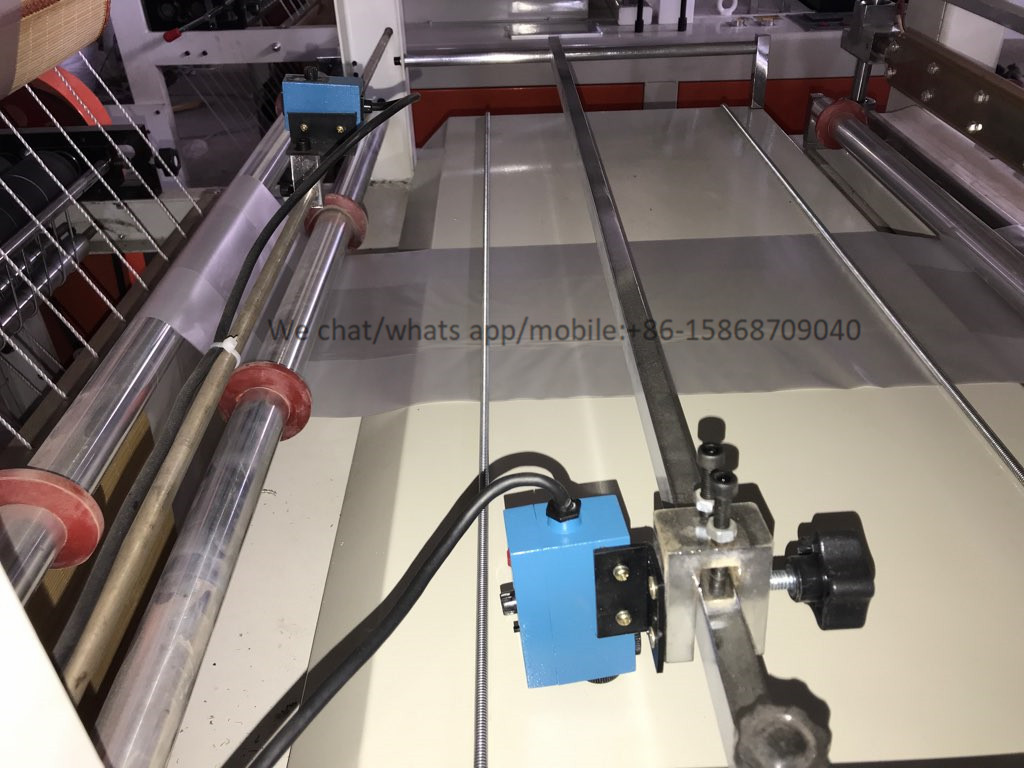

This machine is suitable for producing HDPE and LDPE plastic film, It a adopts the servo motor discharge the material high speed and photocell to track the cutting . Punch the “u” shape bag in one time and with such features. such as easy operation, high efficiency and high finished products.

|

| MODEL | LC-SHXJ-C800 |

| Sealing And Cutting Width | 180-780mm(2 layers up and down) |

| Sealing And Cutting Length | 300-800mm |

| Bag-Making Speed | (50-100)X2 |

| Sealing And Cutting Thickness | 0.015-0.04mm |

| Material | HDPE LDPE LLDPE |

| Air Compressor | 5KG/cm² |

| Main Motor Power | 1.5Kw |

| Overall Dimensions(L×W×H) | 3200x1400x1800mm |

| PERFORMANCE |

| 1. The whole machine adopts micro computer control and material-pulling by stepping motor(Servo motor can also be as an option) |

| 2. Arbitrary length fixing, accurate and stable photoelectric tracking stopping automatically when the label is lost, stepping motor control feeding. |

| 3. Automatic bag number counting alarm. |

| 4. Automatic constant temperature control makes the sealing of bag opening firm and smooth. |

| 5. Non-printing material can make bags in double lines by 4 rolls feeding, making 4 bags in one time. |

Details |

| 1. Application material: HDPE/LDPE |

2. Main drive: A.C 1 set Inverter 1 set

|

a) Feeding motors DC motors 2 sets to control unwinding material feeding b) Photoelectric tracking 1 set back film tracking, edge correction c) One unwinding station d) Brake system for unwinding

|

4. Single Microcomputer control, with functions as: -bag length setting, -display of cutting speed, -bags counting, -shift between printed bag and non-printed bags, -batch setting, heating temperature control, -patch machine control

|

5. Bag-making section b) For both natural color bag and printed bag width≤600mm, it can

cut two lines at a time e) Equipped with static-remover device.

|

6. For bottom sealed bag production

|

Package picture: