Higee Machinery (Shanghai) Co.,Ltd |

|

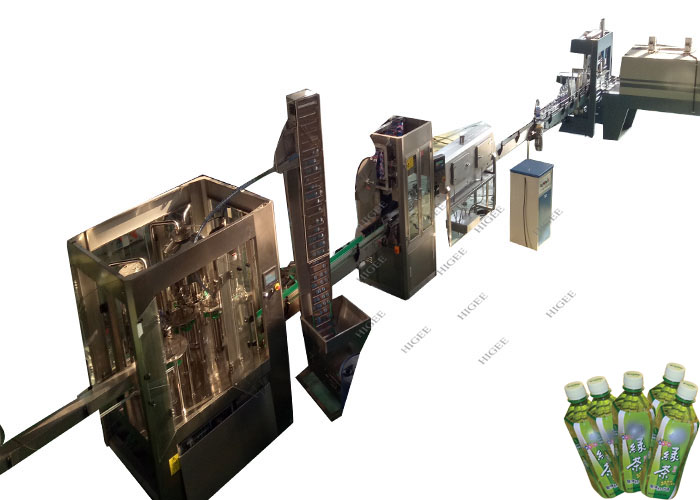

SUS 304 Stable Olive Oil Filling Machine , Beer Bottling Machine For PET

Automatic beverage filling machine for PET , olive oil filling machine,beer filling machine,eliquid filling machine

Our machine introduction:

The suspending bottle-neck clamping design assures whole juice bottling machine more stable during the working process and it also avoids malfunctions caused by the different bottle thickness or height. The design also dramatically reduces the required quantities of interchange parts which make it more convenient to change different types of bottles on washing, filling and capping. Advanced pump filling technology which assure quick filling and high accuracy of liquid level control. Magnetic torque is applied on bottle screw capping. Constant screw capping power can be adjustable and therefore will not hurt the bottles at all. Horizontal swirl cap sorting device is applied to avoid damaging caps. No caps, no capping; No caps, feeding system run automatically. Workers can operate the machine easily because it adopts Human-machine interface touch-screen and PLC control system. If There is No bottles, the machine will stop filling and capping.Liquid level in the tank is controlled automatically. All parts connected with water are made of food grade stainless steel. All main components makers are world-known manufacturers

Technical parameter:

| Model | CGF24-24-8 |

| Production capacity | 8,000-9,000B/H(basis on 500ml bottle) |

| Filling precision | ≤±5mm(liquid level) |

| Polyester bottle specification | bottle diameter:φ50-φ120mm bottle height: 150-340mm |

| Suitable cap type | plastic screw cap |

| Water pressure of washing bottle | 0.18-0.25Mpa |

| water consumption for washing bottle | 2500Kg/h |

| Spraying position | 6 |

| Dripping bottle position | 3.5 |

| Gas source pressure | 0.4Mpa |

| Gas consumption | 0.4m3/min |

| Total power | 5.5Kw |

| Overall dimension | 2750×2180×2200mm |

| Total weight | 4500Kg |

Our machine pictures :

Our machine advantage

Guarantee:

We response for one year warranty for the machine, however, it

without any human conduct. And provide one-year free spare part for

client. And send engineer to client’s company with client’s

provision for flight charge and accommodation. Help install the

machine, teaching their staff operate the machine and also, we do

have a private school which help our client sending their staff to

china, help them training.

After sales service:

1.Installation & adjustment

After the equipment are arrived at the customer’s site, the

customer is responsible for unpacking and arranging the equipment

according to the placement drawing; and does under our

install-adjust technicians’ guidance. Costs of the staff are

decided at last.

2.Training

We are responsible for offering the technical training to user. The

training content includes the structure and maintenance of the

equipment, control and operation of the equipment. Through

training, users' technical staff can grasp and the skill of

operation and maintenance proficiently, and deal with the general

troubles in time. We will appoint qualified technical staff for the

guidance.

The buyer can send staff to our company for learning.

3.Quality assurance

We guarantee the goods offered are brand-new, not used, with latest

design and suitable material made, and we guarantee the

specification of the equipment is consonance with the contract.

We guarantee the line achieve product technical performance

indicators within 5 days after feeding operation through the

correct guidance of the installation and commissioning.

We are responsible for the fault and damage of the production line

caused by our design, technology, manufacture, installation,

adjustment and material defect etc. that all belong to our

responsibility.

The warranty period is 12 months after acceptance check of the

production line. If there is any different between the furnished

equipment in the customer’s factory and the equipment concerned in

the contract, the users have the right to pass the inspection book

to the legal department to claim for compensation to our company

within goods warranty period.

4.Warranty

Offer 12 months maintenance period to the problem that caused by

our design, manufacture and the material quality, and offer the

relevant parts and effective service for free for above reason. We

will offer a widely and favorable technical support, after service

all the time after guarantee period.