Lemon / Pineapple Juice Filling Making Production Equipment Line

Prices

Product introuduction

This machine integrated sterilizing, rising, filling and capping

four functions in one unit, it has 40

sterilizing heads, 40 rising heads, 40 filling heads and 12 capping

heads, can filling 20,000

bottles per hour, suitable for PET bottle, non-gas liquid, like

various juiced beverage, water etc.

Features

1) Material of filling valve and liquid tank is 304

2) Main motor:National brand

3) Sliding bearing:Taiwan

4) Frequency inverter: MITSUBISHI

5) Touch screen:Taiwan

6) PLC: MITSUBISHI

7) Pneumatic components: Airtac

8) Seals:National brand

9) Photocell switch and proximity switch:Taiwan

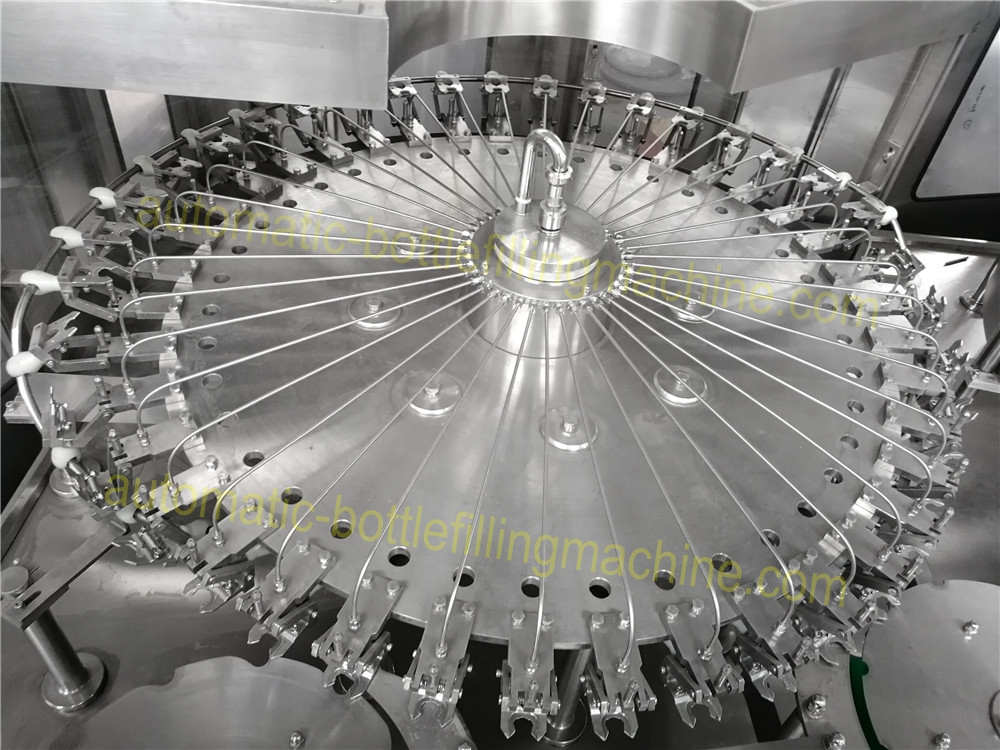

Machine pictures

sterilizing, rising

The automatic rinse rotor has spring loaded grippers mounted

radially which pick up bottles

one by one from the infeed transfer rotor. The bottle is

inverted against a lever on the rinse valve

to start the rinsing operation. Thus we have NO BOTTLE - NO RINSE.

Bottles are washed for

upto three seconds each, before draining ( for removal of residual

water ) and uprighting for

transfer to the filling rotor. The rinsing medium is generally

product water.

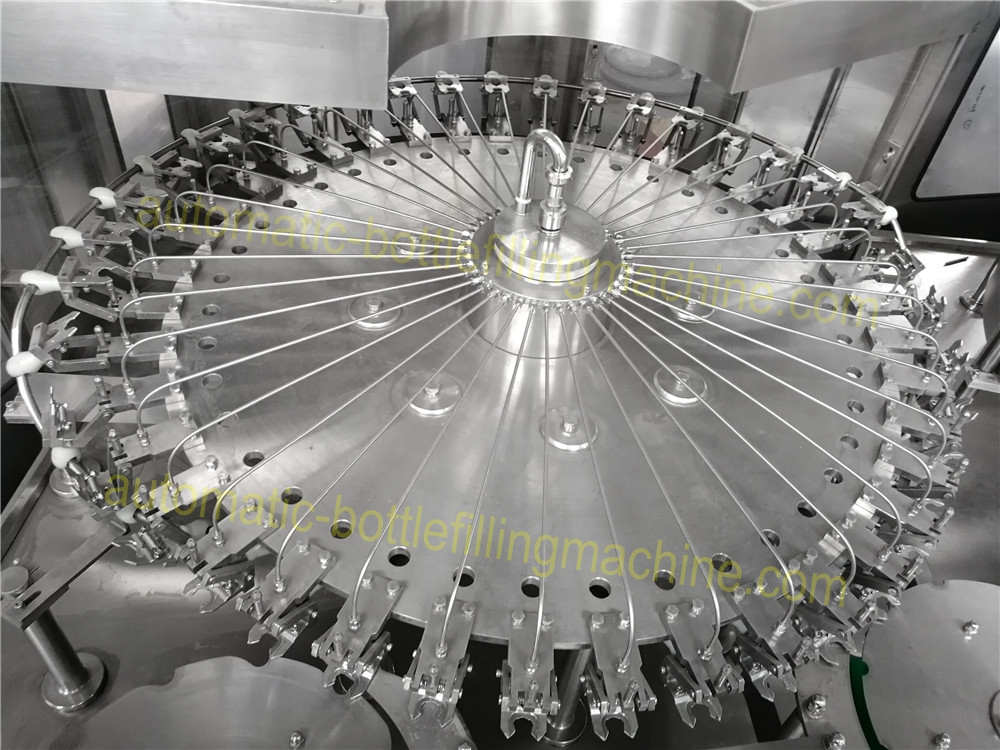

filling

The internationally accepted and approved VENT PIPE filling

principle ensures accurate level

filling without spillage. The filling accuracy is ± 5 ml. The fill

tank level is regulated automatically by

a PLC controlled electronic probe which reduces the machine speed

in the vent of disrupted input

product water supply. The machine speed is then restored to normal

once the water supply is

replenished.

Capping

Torque adjustable, magnetic capping heads mounted on the capping

rotor, complete the capping

operation using the extremely dependent PICK & PLACE mechanism.

Capping head descends

to push up the cap in two stages and then descends onto the bottle

neck to complete capping

operation. The torque on each capping head can be adjustable to

achieve optimum capping

results without cap damage / leakage. A unique anti turn device

prevents bottle rotation during

capping for positive capping.

Detailed parameter

| | 20000BPH 500ml / 10000BPH 1L/ 7000BPH 1.5L/

5000BPH 2L juice filling machine |

| Machine model | Sterilizing head | 40 | heads |

| Rinsing head | 40 | heads |

| Filling head | 40 | heads |

| Capping head | 12 | heads |

| Suitable bottle | materail | PET | |

| Volume | 100-2000 | ml |

| Body diameter | 50-108 | mm |

| Body height | 50-310 | mm |

| Suitable cap | material | Plastic screw cap | |

| diameter | 28-38 | mm |

| Main performance parameters | Producing capacity | 6000BPH(250ML-500ML) | bottles per hour |

| voltage | 380V 50HZ 3Phases | |

| Power | 10 | KW |

| Dimension | 6250*3050*2300mm | mm |

| Weight | 7500 | kg |

We are professional in beverage filling machine production, pls

tell

us your request, we will show you best proposal... ...