Zhangjiagang Jinyate Machinery Co., Ltd |

|

Automatic Liquid Bottle Filling Machine Plant Price For Water / Juiced

Beverage / Other Non-Gas Liquid

product description

this is our smallest monobloc, it integrates rising filling capping three functions in

one unit, it has 8 rising heads, 8 filling heads, 3 capping heads, can fill 3000 bottles

per hour, it's a ideal equipment for small scale production.

Water filling machine is used to fill pure water, mineral water and other non-carbonated beverage.

All the machine part which contact with liquid is high quality stainless steel 304. The relative

fittings are from international famous brand.

This machine is comprised of rinsing, filling and capping system. Rinsing: grip the bottle neck,

rotate filling plate, inverse bottle; internal rinsing and external spraying make bottles be cleaned

completely. Filling: gravity filling with holding bottle neck; the special backflow type of the filling

valve can avoid leakage after filling and also control liquid level accurately. Capping: magnetic

torque bottle holding type can minimize the cap damage rate and make the capping performance

the best.

This machine owns the reasonable, stable and safe design. Under the condition that the bottle

neck size is the same, only the output star wheel needs to be changed if bottles are different. It

improves the efficiency a lot.

We are the water filling machine manufacturers in China.

technical parameter

| Model: | CGF8-8-3 |

| Capacity:500ml(b/h) | 2000 |

| Suitable Bottle Height(mm) | 130-280 |

| Suitable Bottle Body Diameter(mm) | Φ40-φ80 |

| Suitable Cap Shape | Plastic Screw Cap |

| Filling Precision | ≤±5mm(Liquid Level) |

| Power: (KW) | 3 |

| Filling Temperature: | Room Temperature |

| Water Pressure of Washing Bottle(Mpa) | 0.18 |

| Water Consumption for Washing Bottle(kg/hr) | 800 |

| Gas Source Pressure(Mpa) | Normal Pressure |

| Gas Consumption(m 3 /min) | 0.3 |

| Size L×W×H (mm) | 1900x1400x2350 |

| Total Weight:(kg) | 1500 |

| Power Supply | 380V/50HZ |

Machine pictures

overall look

inner look

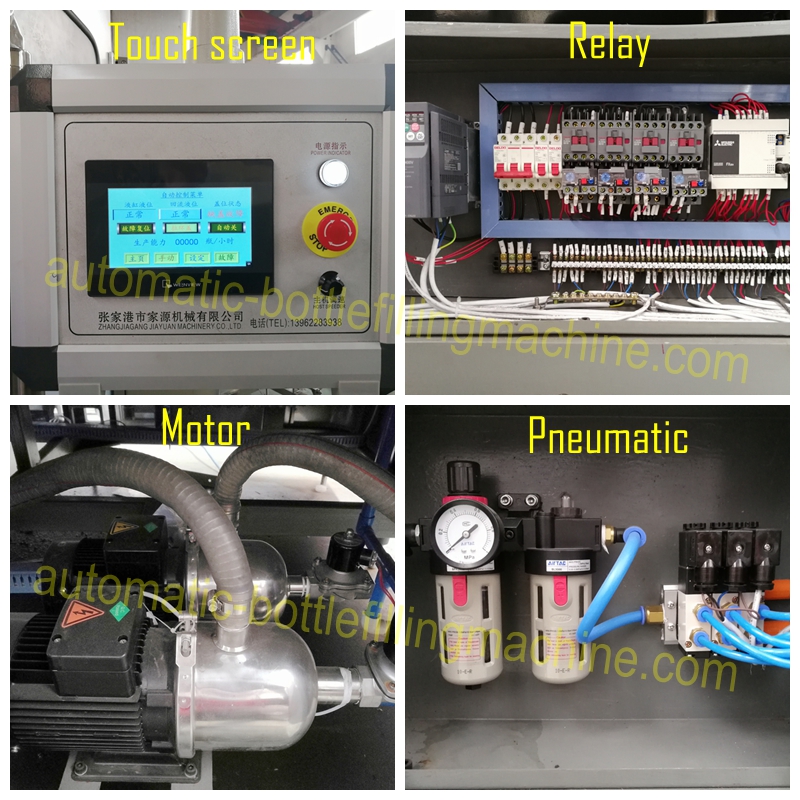

electrical system

working process of the plastic bottle filling machine:

1.Rinsing

Rotative rinsing turret one treatment, fixed nozzles, with grippers. The grippers take the bottles

from the inlet starwheel while they are still driven by the starwheel, thus guaranteeing a safe grip.

After the gripping, the bottle is turned upside down and centred above a spraying nozzle which

directs a stream of rinse water into the bottle. After the draining period the bottle is turned over to

an upright position again.

2.Filling

The starwheels drive the bottles always "by the neck" through the rinsing, filling and capping

step.For the various types of bottle, it is easy to adjust the structure for the operator by our

specializeddesign.Product bowl is to reduce the loss of heat.If the temperature is low than the

setting value, the filling valves will stop and return the last beverage in filling valve to recycle tank

and return to UHT again to sterilize with pump.

3.Capping

Rotative capping turrent, suitable to the application of screw plastic caps on PET bottles. The

fixed part consists of the cap hopper, the cap feeder with relevant motor and the cam actuating

the capping heads.The heads are raised and lowered by the action of a follower that is riding on

a shaped cam.

we also have other capacity

| Model | CGF16-12-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-15 |

| Number of rising heads | 16 | 18 | 24 | 32 | 40 | 50 |

| Number of filling heads | 12 | 18 | 24 | 32 | 40 | 50 |

| Number of capping heads | 6 | 6 | 8 | 10 | 12 | 15 |

| Bottle standard(mm) | Diameter:Φ50-Φ108 Height:150-320 | |||||

| Rated production capacity(500ml) | 4000BPH | 6000BPH | 10000BPH | 12000BPH | 16000BPH | 24000BPH |

| Installed capacity(KW) | 3.8 | 4.3 | 6.5 | 8.7 | 9.5 | 12 |

welcome you have a furthur learn,we will provide you more

information, it's helpful to learn this machine's market price... ...