Qingdao Huichen Logistics Technology Co.,Ltd |

|

High Density storage racks of Radio Shuttle Racking and Pallet Runner

Radio shuttle racking, or called as Pallet mole racking, or called Radio Shuttle Rack, or called as Pallet Runner Racking concept

Radio shuttle Rack system consists of supporting rack, shuttle

rails and a Radio shuttle cart (Also Called Pallet Runner or Pallet

Mole). The Radio shuttle cart runs on the rails and is propelled by

an electric motor. It also has a platform on the top that can lift

up and down. The lifting action is required to lift a pallet that

is placed on the rail and then the electric motor moves the cart

with the pallet on top into the rack in order to deposit the pallet

in its right position.

When the pallet is required, the cart moves in under the pallet,

lifts it and brings it to the front of the rack where it can be

retrieved by a forklift.

All the movements of the shuttle cart are controlled with a hand

held remote control. The shuttle cart is placed in the desired lane

with a forklift.

Advantages

Radio Shuttle Cart is a fully programmable deep lane storage and retrieval system used to transport pallets within a racking structure for maximum storage and throughput of bulk stored items. Radio shuttle rack system allows for more pallets to be stored in a given area when compared to normal static rack .It also minimizes damage to the rack because the forklift does not have to travel into the racking, as is the case with drive-in rack. Accessibility is increased because all the levels can be accessed at any time. In a drive-in rack system the bottom level must be cleared first in order to be able to access the higher levels.

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

Characteristic

· 100% accessibility to individual pallets

· Easy picking lower levels

· Good storage density

· Easily installed and repositioned

· No special lift trucks required

| Performance of Racking System | Bulk Storage | Selective Pallet Rack |

| Selectivity of individual pallets | 40% | 100% |

| Use of floor space | 80% | 50% |

| Utilization of pallet posting | 70% | 98% |

| Speed of access and throughput | 80% | 80% |

| Stock rotation (FIFO) | 40% | 60% |

| Use of building height | 30% | 80% |

| Efficient Bottom Level Case Picker | No | Yes |

| Ease of relocation | 100% | 100% |

| System adjustability | 100% | 100% |

| Specialist handling equipment | No | No |

Shuttle

Radio Shuttle Rack has a battery-operated motor inside that can run for a full 8-hour shift before it needs recharging. It also has censors that can pick up its location within the rack and in relation to the pallet it needs to deposit or retrieve thereby reducing the monitoring by an operator. It has a robust shell with easy access to parts that needs maintenance. All the components used are locally sourced "off the shelf" components to ensure availability in case of a breakdown.

Radio Shuttle cart can provide the perfect solution to dense storage situations. One of the conventional methods would be to install drive in racking which is great at space utilization but can sometimes inhibit efficiencies when storing the deep pallets as well as potential damage to uprights.

Radio shuttle rack gives the same space utilization but removes the inefficiencies and risk of damages. All the forklift operator needs to do is place a pallet onto a shuttle position and activate the shuttle and it does the rest of the work, freeing up the operator to complete other tasks.

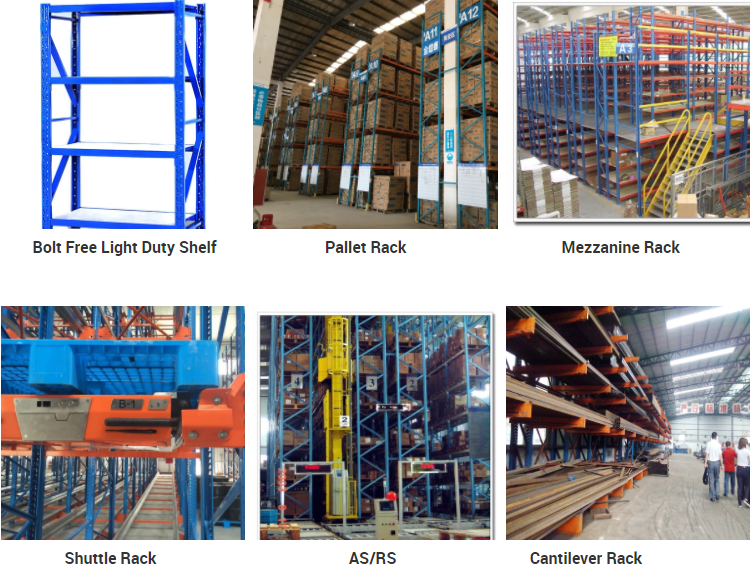

Main Products

Production Of Radio Shuttle Rack

Contact Us:

Email: heidi@huichen.cn

Mobile/Whatsapp: +86 176 6062 0398