Shanghai Npack Automation Equipment Co., Ltd. |

|

Automatic spindle scrw capping machine

Automatic capping machine is flexible, durable and works with most containers and caps includingflat caps, sport caps, metal lids and many others.The machine has practicability in field of pharmaceutical, pesticide, chemical, foodstuff etc. It is real ideal equipment for bottle screw capping, also applied to seal aluminum cap, the ft proof cap, screw-thread cap, ROPP cap etc. It's built on a heavy duty, tig welded, stainless steel frame with anodized aluminum plate construction to provide durability in almost any packaging environment. The modular design lets you start with just a cap tightener and easily add capabilities when you need them.

Features:

Power height adjustment

Gripper Belt height and width adjustment

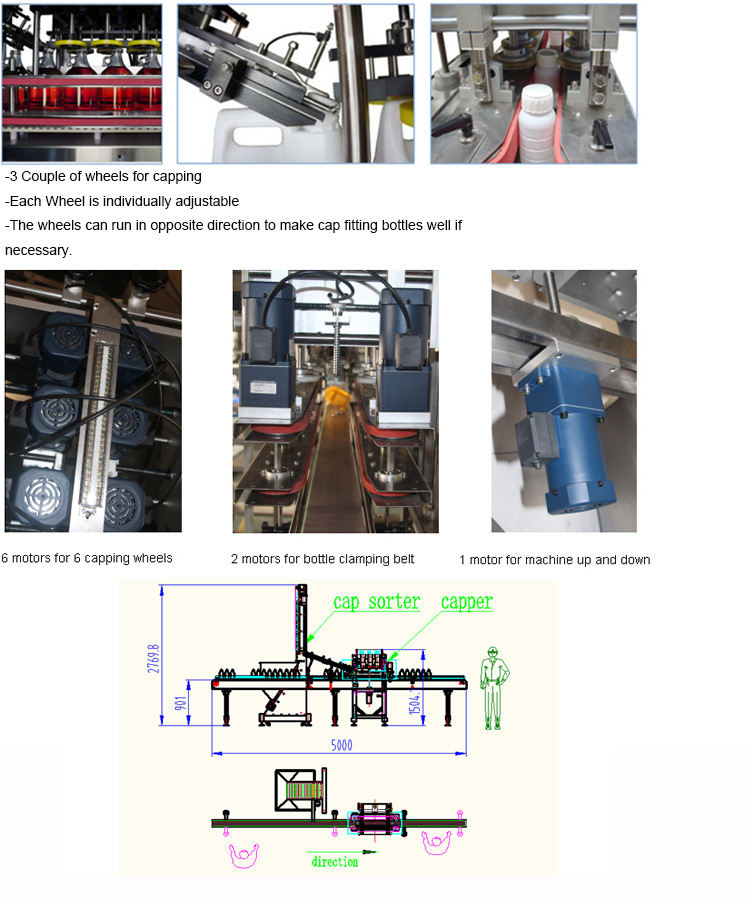

Spindle Wheels Spindle Wheel adjustment knobs, with lock nut hand

wheel

No change parts required for a wide range of containers

Sanitary 304 stainless steel drive shafts and adjustment support

shafts

Timing belt power transmission for Spindle Wheels

Bottom screw changeover on Spindle Wheels

1/2” aluminum mounting plates and 1/2” hard coat anodized supports

on Cap Feed Chute

Removable dual gripper belts

Trigger spray cap rails

Techniacal paramater

| NO1 | Item | Automatic Capping machine |

| NO2 | Cap Diameter | 20-120MM |

| NO3 | Bottle Height | 45-460MM |

| NO4 | Speed | 60-200BPM |

| NO5 | Voltage | 220VAC |

| NO6 | Power | 1600W |

| NO7 | Air Pressure | 0.6MPA |

| NO8 | Weight | 500KG |

| NO9 | Dimensions | 1080*900*1700 |

| NO10 | Option | Cap Sorter |

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD,

Installation and Debugging

-- We will send engineers to carry out installation and debugging

of the equipment in buyer's place if requested.

-- The cost for International double ways air tickets,

accommodations, food and transportations, medical shall be paid by

Buyer for the engineers.

-- The normal debugging term is 3-7days, and the buyer should pay

US$80/day per engineer.

-- If customer do not require above, then customer need to be train

in our factory. Before installation, the customer need read the

operation manual firstly. Meanwhile, we will offer an operation

video to customer.

Training

-- We offer machines training system; the customer can choose

training in our factory or in customer workshop. The normal

training days are 1-2 days.

Warranty

-- The sold machine will be guarantee in one year.

-- In the guarantee year, any spare parts broken due to supplier's

quality issue the spare parts will be supplied free for customer,

customer need to pay the freight cost if the parcel weight more

than 500gram.

-- The easy wearing out spare parts are not in the warranty terms,

such as O rings, belts which will be supplied with the machine for

one year using.