Qunxingwang Mould Technology Co.,Ltd |

|

customized design automotive plastic products/auomotive plastic

products OEM injection mould/auto plastic injection mold

Description:

| Surface treamment | Texturing,polished | ||||||||

| De-mold Type | Automatic eject | ||||||||

| Mold Base | LKM, | ||||||||

| Mold Material | 2344 | ||||||||

| Mould Cavity | 1 | ||||||||

| Sprue Gate | Hot runner, Cold runner , Submarine gate | ||||||||

| Design Software | UG,PROE,CAD | ||||||||

| Plastic Material | ABS | ||||||||

| Main processing equipment | CNC, EDM, Milling machine, Grinding machine, Injection machine | ||||||||

| Moild Life | 300000-1000000 shots | ||||||||

| Cavity/core steel | NAK80,S136,2316,2738,H13,S7,718H,2344 | ||||||||

| Steel hardness | HRC48-52 | ||||||||

| Cycle time | 40 seconds | ||||||||

| Design time | 3 days | ||||||||

| Specification | As your requirements | ||||||||

| OEM order | Greatly welcome | ||||||||

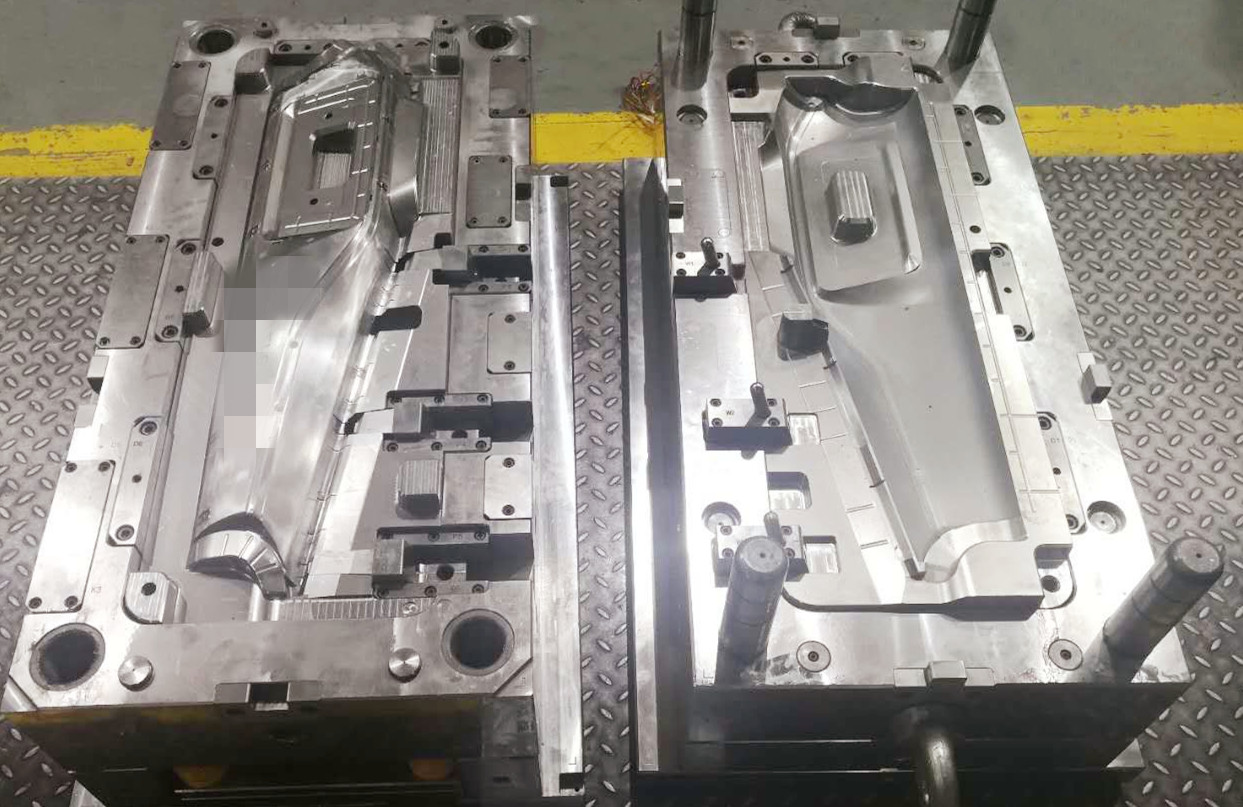

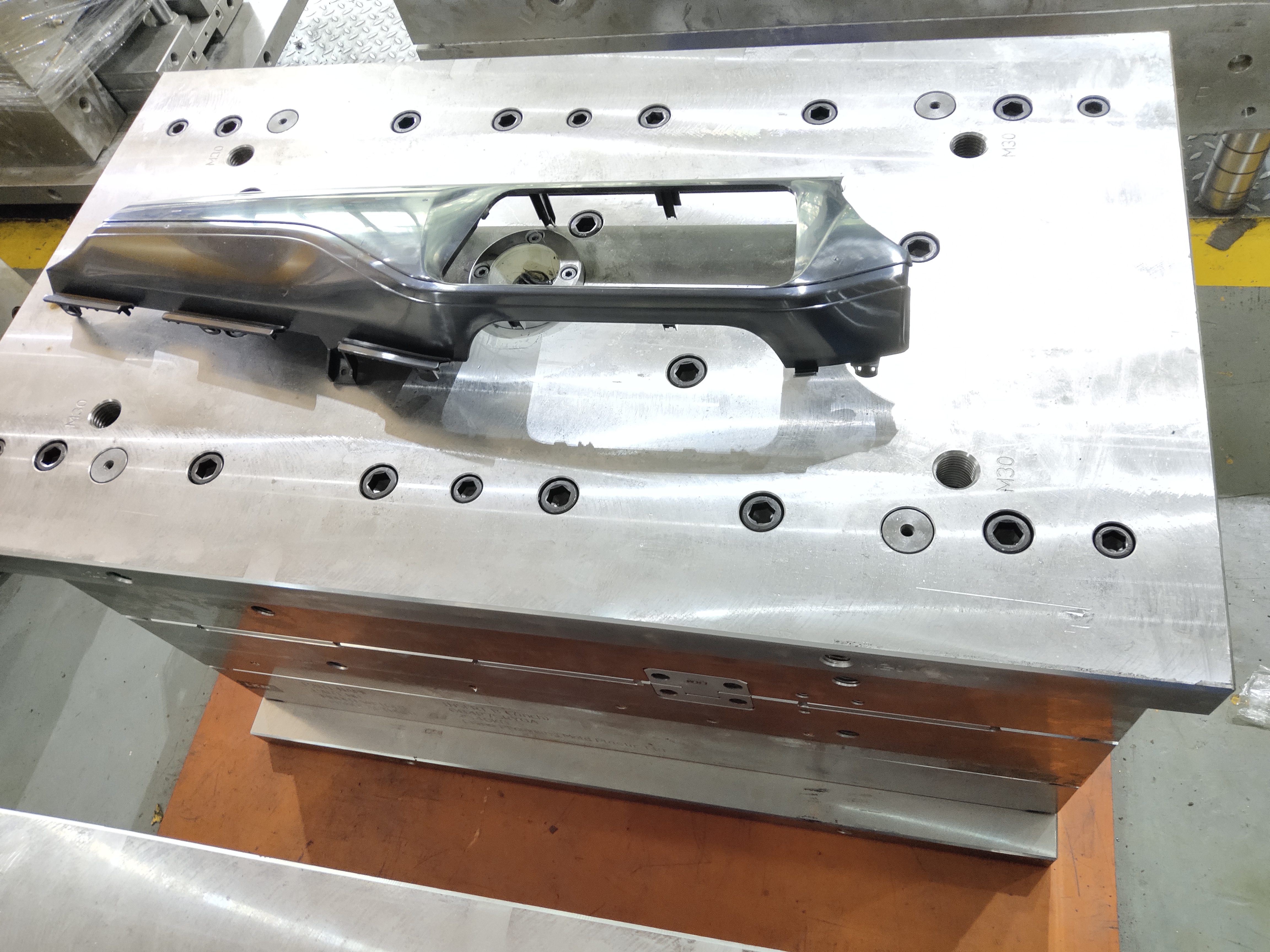

Detail image:

1. the mould surface of cavity and core will be covered with anti corrosive oil.

2. the guide pin and guide bushing will be covered with

butter.

3. the mould will be wrapped in plastic film.

4. the mould will be packed in customized wooden case.

5. the wooden case will be strapped with metal bands.

6. some other spare parts will be put into the wooden case together

with mould, there are material certificate, mould data

CD, hot sprue , lifting bolt , ejector pin etc.

Our Services:

Qunxingwang Mould company project team can deal with some other service for customers, such as products surface treatment: screen printing, painting, assembly and other services. Our company has long-term cooperation of the enterprises in China. Our team can provide customers with free services in these areas. We can provide one step service for our customers.

Advantages of our plastic injection mould :

We have a professional tooling design team with several years experience.

1. Various materials and short lead-time.

2. Good steel and long lifetime.

3. We can supply "one-stop" service with molds opening, injection,

painting, screen printing, assembly and nice after-sales service in

long term.

4. Full set of machines for mold making and injection molding.

5. OEM&ODM service available.

6. Mould's design based on tooling engineer from our company and

experienced with years in the industry.

7. Mould's steel as per customers' requests such as NAK80,

S1369(H),2738, 718, 738 and etc.

8. Final products' materials' optional: ABS, PP, PE, POM,

PA6(66)+GF, PC, PMMA, HIPS, GPPS and etc.

9. Products' color: As the customer's requirements, any color is

possible, if they could provide us the color card schedule.

10. Service scope: Open mould, Injection, CNC processing,EDM

processing ,coating, screen printing, assembly for finished

products and so on.

11. Good cost and high effeciency of delivery.

FAQ:

A:how about certificate?

Q:We will make 100% full inspection and provide the inspection reports.

A:how to contact with me in effective way?

Q:you can contact me on Email, facebook,LinkedIn,Ins,wechat and then send inquiry with 3D drawing or 2d drawing ,or original sample with size ,and tell us your details requirements ,

like needs to use what material,mould need to make how many cavities.

A:Is it possible to return the money if the quality is not good?

Q:This has never been occured right now ,as we treat the quality as our key of development.Quality and service is everything for us.

Q: Can I test my idea/component before committing to mould tool manufacture?

A:Yes, we can use CAD drawings to make models for design and functional evaluations.

Q:What type of plastic is best for my design/component?

A:Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest to choice which.

Q: If you make poor quality goods,will you refund our fund?

A: As a matter of fact, we won't take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction.

For more information, please contact us !