Qunxingwang Mould Technology Co.,Ltd |

|

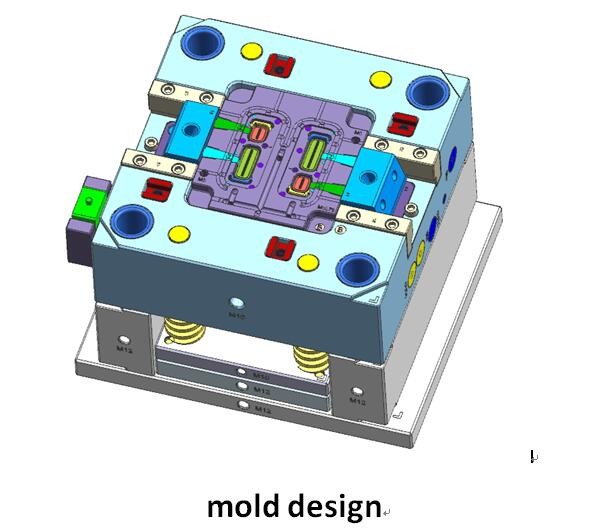

injection molded plastic parts/plastic OEM injection mould/spare

parts plastic injection molding

Description:

| Surface treamment | Texturing,polished | ||||||||

| De-mold Type | Automatic eject | ||||||||

| Mold Base | LKM, | ||||||||

| Mold Material | S50C,P20,420H | ||||||||

| Mould Cavity | 1 | ||||||||

| Sprue Gate | Hot runner, Cold runner , Submarine gate | ||||||||

| Design Software | UG,PROE,CAD | ||||||||

| Plastic Material | PP,PA6,PA6+GF20% | ||||||||

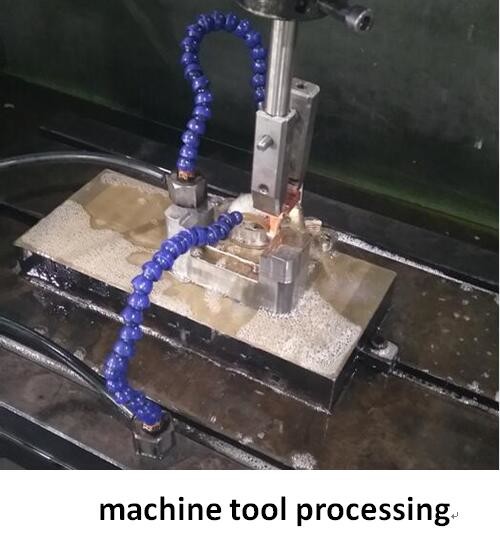

| Main processing equipment | CNC, EDM, Milling machine, Grinding machine, Injection machine | ||||||||

| Moild Life | 300000-1000000 shots | ||||||||

| Cavity/core steel | 2738,718H | ||||||||

| Steel hardness | HRC48-52 | ||||||||

| Cycle time | 40 seconds | ||||||||

| Design time | 3 days | ||||||||

| Specification | As your requirements | ||||||||

| OEM order | Greatly welcome | ||||||||

Our strength:

1. 100 % Manufacturer .

2. Specializing in processing high precision plastic mould and plastic parts.

3. Well-trained and experienced staffs .

4. More than 10 years rich experience .

5. Concept of custom first.

FAQ:

Q1: How can I get product price from you ?

A2.: Please send product information by email, will reply in 24 hours.

Q3 : What information should I give to you for inquiry?

A3 : If you have drawings or samples,please feel free to send us,and tell us your special requirements such as material ,tolerance,surface treatments and the amount you need,ect .

Q4: How about the quality ?

A4: We will make 100% full inspection and provide the inspection reports, keep high quality always.

Q5: Is it possible to return the money if the quality is not good?

A5: This has never been occured right now ,as we treat the quality as our key of development.Quality and service is everything for us.

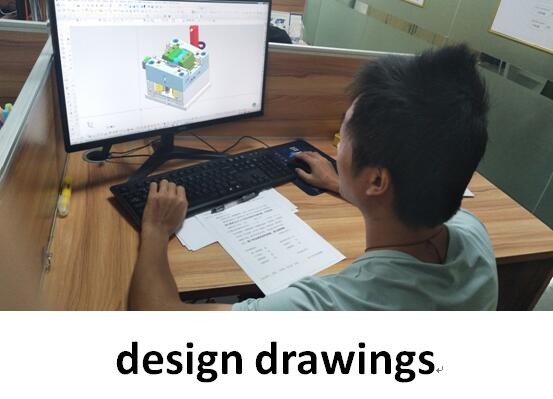

Professional Team:

1.Our team has strong energy and capability to help you achieve your idea : design –production - surface

treatment - assembly - package –shipment etc.

2. Skilled designer with related software (UG,PROE,CAD etc. ) can

draw your products

3 .Professional knowledge will solve every difficult problem .

4 .With strong responsibility and good communication to reach high

efficient and accurate work .

5. Excellent team work will meet your various requirements .

1. the mould surface of cavity and core will be covered with anti

corrosive oil.

2. the guide pin and guide bushing will be covered with butter.

3. the mould will be wrapped in plastic film.

4. the mould will be packed in customized wooden case.

5. the wooden case will be strapped with metal bands.

6. some other spare parts will be put into the wooden case together

with mould, there are material certificate, mould data

CD, hot sprue , lifting bolt , ejector pin etc.

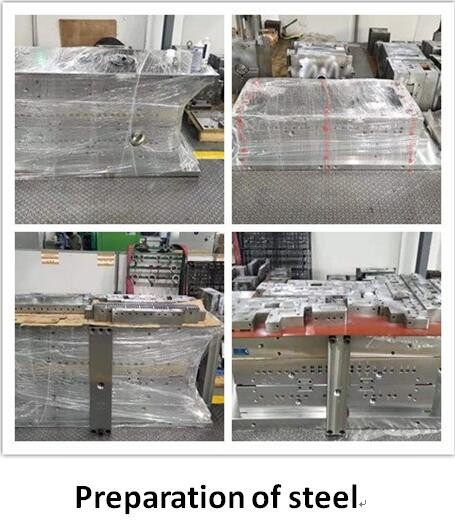

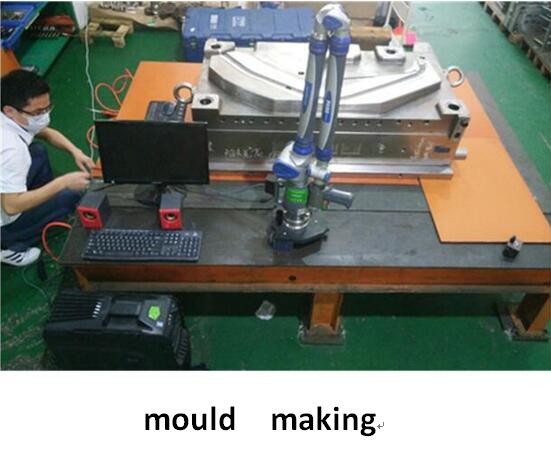

Production equipments:

Production processing:

related mould show:

related plastic parts: