LeadTop Pharmaceutical Machinery Co., LTD |

|

Verified Suppliers

|

|

he magnetic mixer, a fully closed, non-leakage, non pollution mixing, is installed at the bottom of tank. Because the sanitary magnetic agitator is a non-contact transmission torque with no transmission shaft, it is made by magnetic drive. The dynamic seal was replaced by the static seal, which solved the problem that the other shaft seal could not overcome the leakage. The whole material and the stirring parts were operated in a sterile and sanitary state. It is pharmaceutical, fine chemicals, cosmetics, bioengineering and other industries ideal replacement products.

Application scope: mixing device for all kinds of reactors, mixing tank and storage tank

Working condition: inflammable, explosive, easy to leakage, high requirement on sealing

Technical parameter: working temperature:-20~220℃

Material: 316L or 304

Working pressure: -0.1~0.6Mpa

Model selection description: should know the change of viscosity and density, working temperature and working pressure

Working characteristics

Sanitary magnetic mixers are designed for GMP modification in pharmaceutical, bioengineering and food industries.

Good performance, reasonable structure, small volume and reliable use.

The mixer is composed of inner magnetic steel, external magnetic steel, isolation sleeve and driving motor.

It is applied to mixing device of stainless steel reactors and mixing tanks.

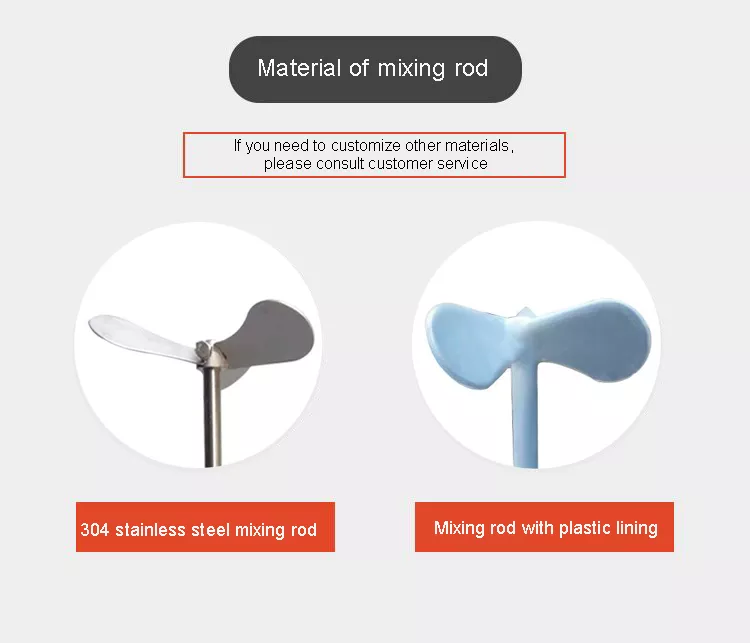

All the contact materials of the magnetic agitator are made of 316l/304. The working principle of permanent magnetic coupling is used to drive the operation of stirring shaft. The dynamic mechanical seal is replaced with static mechanical seal, which solves the unavoidable problem of mechanical seal. The magnetic agitator produces a whirlpool by rotating, sucking dissolved powder or liquid into the swirl and being quickly sucked into the stirring impeller.

When the suction direction of the impeller rotates with the impeller, the centrifugal force impinges different media into the tank wall in the form of radiation from the outer diameter of the impeller.

After hitting the tank wall, the liquid is sucked back to the suction end of the impeller with impact force and rising cycle.

The constant moving agitation under the impeller thrust results in homogenization, mixing, dissolution and dispersion.

Technical Data

| Material | Contact with the product parts | 316L |

| Non contact product parts | 304 | |

| Viscosity | Max viscosity CP | 300CP |

| Pressure | Design pressure | -1~6bar |

| Temperature | Working temperature | -20~220℃ |

| Surface treatment | Internal surface finish | Ra0.4~0.6μm |

| Connection | Weld | |

| Installation | Horizontal/vertical | |

| Volume | 30L-30000L | |

| Motor- decelerator | 0.37-18kw/110V-480V | |