KUNSHAN YGT IMP.&EXP. CO.,LTD |

|

Verified Suppliers

|

|

SUS304 GKD Brand Press Belt 10T/H Capacity Belt Press Belt Machine For Pineapple

SUS304 GKD brand press belt 10T/H capacity

Belt Press Belt Machine For Pineapple

1. Advantage for Belt Press

High-quality materials and the consistent use of stainless steel

make the belt press durable and wear-resistant. Various precautions

are taken to ensure the safety of the operating personnel.

High process reliability can be achieved thanks to the Siemens

electrical control. It enables optimum interaction of all process

components and sets the highest standards for operational safety,

even when in-house components are integrated.

2 . Specifications for Belt Press

| Model | DYJ-3 | DYJ-5 | DYJ-10 | DYJ-20 | |

| Production capacity(t/h) | 1~3 | 3~5 | 10~12 | 20~22 | |

| Total power | 20.38 | 21.18 | 22.25 | 41.37 | |

| Main drive moto speed(r/min) | 8 | 8 | 8 | 5 | |

| Linear velocity of filter belt (m/min) | 5 | 5 | 5 | 5 | |

| Feed feight(mm) | 1900 | 1900 | 2000 | 1920 | |

| Outline size(mm) | 3230×1600×2000 | 4000×2085×2505 | 5000×2880×2505 | 5420×3380×2050 | |

| Host power | 2.2 | 3 | 4 | 5.5 | |

| Power of distributing roller | 0.55 | 0.55 | 0.75 | 0.75 | |

| Compressed air | Pressur (Mpa) | 0.7 | 0.7 | 0.7 | 0.7 |

| oxygen consumption (m³/h) | 1 | 1 | 1 | 1 | |

| Wash water return pump | Power (kw) | 3 | 3 | 3 | 5.5 |

| Flow (m³/h) | 25 | 25 | 25 | 25 | |

| Lift (m) | 20 | 20 | 20 | 20 | |

| Spray high pressure pump | Power (kw) | 15 | 15 | 15 | 15*2 |

| Flow (m³/h) | 16 | 16 | 16 | 16*2 | |

| Lift (m) | 165 | 165 | 189 | 189 | |

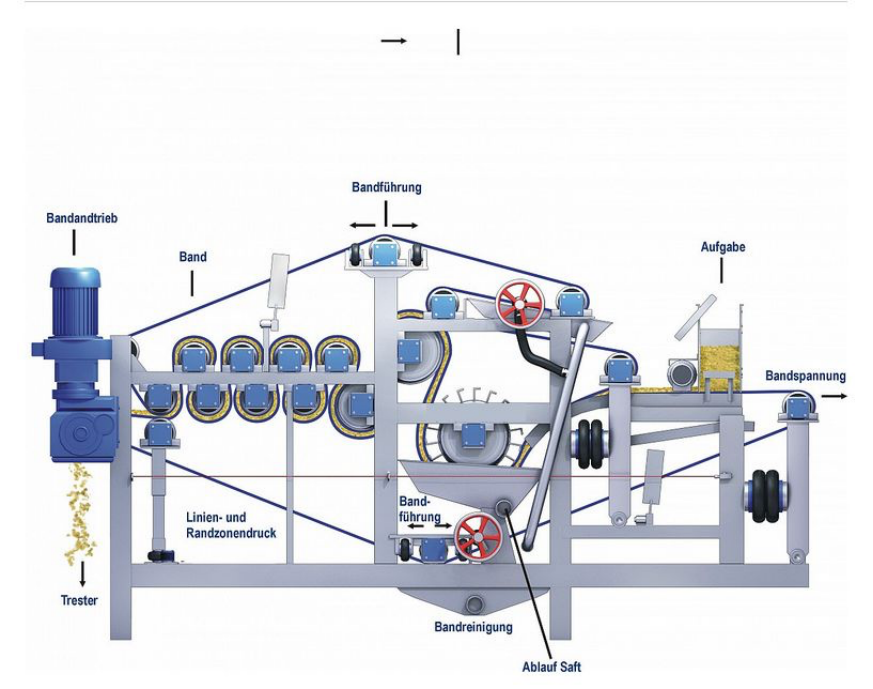

3. More Picture for Belt Press

Production Process for Belt Press

The refined raw materials (solid liquid mixture) are continuously pumped into the hopper by the progressing cavity pump (the bandwidth occupied by the material can be adjusted) and distributed evenly by the distributing roller. A large amount of water is slowly squeezed out of the lower wedge to form a squeezable filter cake, In the press area, a pressure roller with an "L" shaped strip presses out the water and ensures that the water flows out quickly on both sides. The diameter of the press roller at the back is decreasing, and the filter belt is in the shape of "S", which produces a shear force of decreasing surface pressure, which ensures the dehydration effect. To further increase the rate of dehydration, a pressure roller is added to generate linear pressure and peripheral pressure. After dehydration, the filter cake is scraped by wear-resistant scraper. The two filter belts are continuously washed by high-pressure nozzle, so that the filter belt can keep the effect of juice. Spray washing water through the reflux pump through the arc filter screen automatic filtration, slag discharge, recycling use, energy saving. The filter belt is made of nylon yarn warp and weft.

4. Feature and Advantage for Press

• Main structure made of SUS 304 stainless steel.

• Using Mirror welding tech to ensure tidy and smooth welding line.

• Advantages of energy saving

5. Usages for Belt Press

Belt type juicing machine is widely used in juice extraction and environmental protection process of fruits and vegetables and Belt type juicing machine can also be used for pressure filtration and dehydration of powdery materials in chemical industry, environmental protection, light industry and other industries.

6. Service for Belt Press

(1)Reply in 24 hours

(2)Providing professional solutions

(3)Every product will be tested before the delivery

(4)Delivery on time and excellent after-sale service

(5)High quality, reliable price