NINGBO NIDE MECHANICAL EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

|

High Efficiency BLDC Motor Needle Winding Machine Stator Automatic Winding Machine

(1) Technical parameter of BLDC motor needle winding machine:

| Product name: | BLDC Motor Needle Winding Machine |

| Statck ID: | ≥25mm |

| Stack OD: | ≤150mm |

| Stack height: | 10~100mm |

| Suitable wire diameter: | 0.3~1.0mm |

| Power supply: | 220V 50/60HZ |

| Weight: | 600KG |

| Dimension: | 1400x900x2000 |

(2) Application:

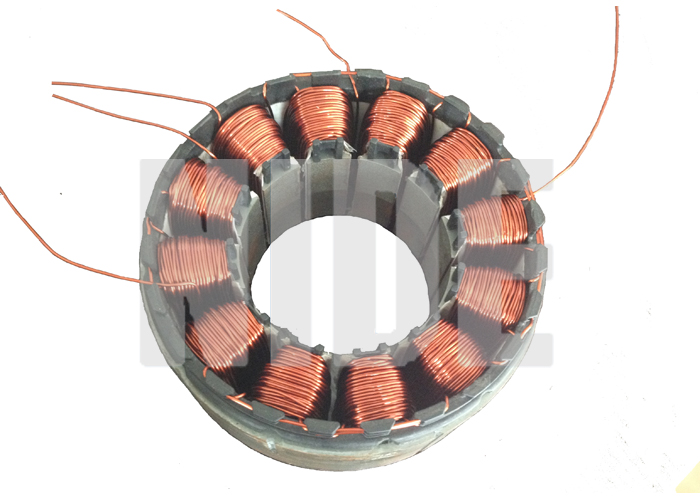

This stator needle winding machine is suitable for winding BLDC

stator.

(3) Machine function and characteristic of BLDC motor needle

winding machine:

This machine is suitable for winding BLDC stator. It equips with

servo system. It can automatically interwine wire end, winding,

arraying, indexing, cutting, demolding.

BLDC needle winding machine.pdf

Please click below picture to view video.

Nide is a company devoted in the field of electric motors manufacturing, providing one-stop service for its customers. Nide has three main business divisions. The first division is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line,motor stator winding machine, staor insulation paper inserting mahcine, stator coil inserting machine , ,bldc / brushless motor winding machine,motor armature / rotor winding machine and rotor die casting machine,etc. The second division is to supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc. The third division is to provide technical support and consulting, project support and turn-key service for some motor manufacturing.