Aolittel Technology Co.,Ltd |

|

PVC Overmolded Remote Room Thermostat Warming Heating Cable Undefloor Micro Temperature Sensor Probe 10KΩ 3950K 6.5x25mm

Overview

The Probe and Sensor are used to control temperature where moisture would be a problem i.e. in wet room or bathroom. It can also control floor temperature where overheating would cause damage.

______________________________________________________________________________ Download________

Download________

Materials

| NO | Material Name | Material and Specifications |

| 1. | Element | R25=10KΩ±1% B25/50=3950K±1% DC |

| 2. | Coating | NTC encapsulated using PVC over-mold material (White) |

| 3 | Cable features | UL2464-22AWG Tin plated copper cable with white PVC flat jacket wire 80℃ 300V

|

| 4. | Wire ends | Tinned |

| Dimension | ||||

| A | B | C | D | L |

| 6.5 | 20 | 25±5 | 3±1 | as required |

Performances

| NO | Item | Sign | Test Conditions | Min. | Nor. | Max. | Unit |

| 1. | Resistance at 25℃ | R25 | Ta=25±0.05℃ PT≦0.1mw | 9.9 | 10.0 | 10.1 | kΩ |

| 2. | B Value | B25/50 | 3910.5 | 3950 | 3989.5 | k | |

| 3. | Dissipation factor | σ | In still air | About 2 | mW/℃ | ||

| 4. | Time response | τ | In flowing water | About 15 | sec | ||

| 5. | Withstanding Voltage | / | 1500VAC 2Sec | No breakdown | Sec | ||

| 6. | Insulation Resistance | 500VDC | ≧100 | MΩ | |||

| 7. | Operating temp. range | / | / | -30 | / | +105 | ℃ |

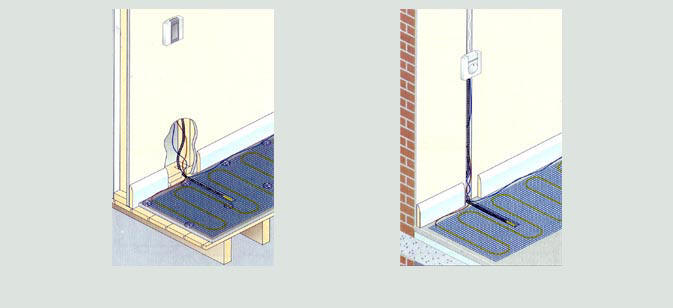

Dry & Solid Wall Instalation

Minco Heat 0.5M2 Twin-Conductor Electric Underfloor Heating Mats For Warm Floor, Underfloor Heating Kits

Resistance Vs. Temperature Table

| R-T CONVERSION TABLE | ||||||||

| R25=10KΩ±1% B25/50=3950K±1% | ||||||||

| T/℃ | Rmin | Rcen | Rmax | T/℃ | Rmin | Rcen | Rmax | |

| -40 | 335.811 | 351.495 | 367.875 | -5 | 41.735 | 42.774 | 43.834 | |

| -39 | 314.029 | 328.472 | 343.546 | -4 | 39.599 | 40.563 | 41.547 | |

| -38 | 293.803 | 307.110 | 320.988 | -3 | 37.586 | 38.480 | 39.392 | |

| -37 | 275.015 | 287.279 | 300.060 | -2 | 35.686 | 36.517 | 37.363 | |

| -36 | 257.552 | 268.859 | 280.635 | -1 | 33.894 | 34.665 | 35.450 | |

| -35 | 241.313 | 251.741 | 262.595 | 0 | 32.203 | 32.919 | 33.646 | |

| -34 | 226.204 | 235.826 | 245.832 | 1 | 30.607 | 31.270 | 31.945 | |

| -33 | 212.141 | 221.021 | 230.250 | 2 | 29.099 | 29.715 | 30.340 | |

| -32 | 199.044 | 207.242 | 215.757 | 3 | 27.674 | 28.246 | 28.826 | |

| -31 | 186.841 | 194.412 | 202.270 | 4 | 26.328 | 26.858 | 27.396 | |

| -30 | 175.465 | 182.460 | 189.714 | 5 | 25.055 | 25.547 | 26.045 | |

| -29 | 164.856 | 171.320 | 178.019 | 6 | 23.851 | 24.307 | 24.769 | |

| -28 | 154.957 | 160.932 | 167.120 | 7 | 22.712 | 23.135 | 23.563 | |

| -27 | 145.716 | 151.241 | 156.959 | 8 | 21.634 | 22.026 | 22.423 | |

| -26 | 137.086 | 142.196 | 147.481 | 9 | 20.614 | 20.977 | 21.345 | |

| -25 | 129.022 | 133.750 | 138.636 | 10 | 19.650 | 19.987 | 20.327 | |

| -24 | 121.485 | 125.859 | 130.378 | 11 | 18.733 | 19.044 | 19.359 | |

| -23 | 114.435 | 118.485 | 122.665 | 12 | 17.865 | 18.154 | 18.445 | |

| -22 | 107.840 | 111.589 | 115.457 | 13 | 17.043 | 17.310 | 17.579 | |

| -21 | 101.667 | 105.139 | 108.718 | 14 | 16.264 | 16.510 | 16.759 | |

| -20 | 95.886 | 99.102 | 102.415 | 15 | 15.524 | 15.752 | 15.982 | |

| -19 | 90.471 | 93.450 | 96.518 | 16 | 14.823 | 15.034 | 15.246 | |

| -18 | 85.395 | 88.156 | 90.997 | 17 | 14.157 | 14.352 | 14.548 | |

| -17 | 80.636 | 83.195 | 85.826 | 18 | 13.525 | 13.705 | 13.885 | |

| -16 | 76.173 | 78.544 | 80.982 | 19 | 12.925 | 13.090 | 13.257 | |

| -15 | 71.984 | 74.183 | 76.441 | 20 | 12.354 | 12.507 | 12.660 | |

| -14 | 68.052 | 70.091 | 72.184 | 21 | 11.813 | 11.953 | 12.094 | |

| -13 | 64.359 | 66.250 | 68.189 | 22 | 11.298 | 11.427 | 11.557 | |

| -12 | 60.889 | 62.643 | 64.441 | 23 | 10.808 | 10.927 | 11.046 | |

| -11 | 57.628 | 59.255 | 60.922 | 24 | 10.342 | 10.452 | 10.561 | |

| -10 | 54.562 | 56.071 | 57.617 | 25 | 9.900 | 10.000 | 10.100 | |

| -9 | 51.677 | 53.078 | 54.511 | 26 | 9.470 | 9.570 | 9.670 | |

| -8 | 48.963 | 50.263 | 51.592 | 27 | 9.061 | 9.161 | 9.260 | |

| -7 | 46.408 | 47.614 | 48.847 | 28 | 8.672 | 8.771 | 8.871 | |

| -6 | 44.002 | 45.121 | 46.264 | 29 | 8.302 | 8.401 | 8.499 | |

| R-T CONVERSION TABLE | ||||||||

| R25=10KΩ±1% B25/50=3950K±1% | ||||||||

| T/℃ | Rmin | Rcen | Rmax | T/℃ | Rmin | Rcen | Rmax | |

| 30 | 7.950 | 8.048 | 8.146 | 67 | 1.881 | 1.932 | 1.984 | |

| 31 | 7.615 | 7.712 | 7.809 | 68 | 1.817 | 1.866 | 1.917 | |

| 32 | 7.295 | 7.391 | 7.488 | 69 | 1.754 | 1.803 | 1.852 | |

| 33 | 6.991 | 7.086 | 7.182 | 70 | 1.695 | 1.742 | 1.790 | |

| 34 | 6.702 | 6.795 | 6.890 | 71 | 1.637 | 1.684 | 1.731 | |

| 35 | 6.425 | 6.518 | 6.612 | 72 | 1.582 | 1.627 | 1.674 | |

| 36 | 6.162 | 6.254 | 6.346 | 73 | 1.529 | 1.573 | 1.619 | |

| 37 | 5.911 | 6.001 | 6.092 | 74 | 1.478 | 1.521 | 1.566 | |

| 38 | 5.672 | 5.761 | 5.850 | 75 | 1.429 | 1.471 | 1.515 | |

| 39 | 5.443 | 5.531 | 5.619 | 76 | 1.382 | 1.423 | 1.466 | |

| 40 | 5.225 | 5.311 | 5.398 | 77 | 1.336 | 1.377 | 1.419 | |

| 41 | 5.017 | 5.102 | 5.188 | 78 | 1.293 | 1.332 | 1.373 | |

| 42 | 4.818 | 4.902 | 4.986 | 79 | 1.251 | 1.289 | 1.329 | |

| 43 | 4.628 | 4.710 | 4.794 | 80 | 1.210 | 1.248 | 1.287 | |

| 44 | 4.447 | 4.528 | 4.609 | 81 | 1.171 | 1.208 | 1.246 | |

| 45 | 4.274 | 4.353 | 4.433 | 82 | 1.134 | 1.170 | 1.207 | |

| 46 | 4.108 | 4.186 | 4.265 | 83 | 1.098 | 1.133 | 1.170 | |

| 47 | 3.950 | 4.026 | 4.104 | 84 | 1.063 | 1.097 | 1.133 | |

| 48 | 3.799 | 3.874 | 3.950 | 85 | 1.029 | 1.063 | 1.098 | |

| 49 | 3.654 | 3.728 | 3.802 | 86 | 0.997 | 1.030 | 1.064 | |

| 50 | 3.515 | 3.588 | 3.661 | 87 | 0.966 | 0.998 | 1.032 | |

| 51 | 3.383 | 3.454 | 3.526 | 88 | 0.936 | 0.968 | 1.000 | |

| 52 | 3.256 | 3.326 | 3.396 | 89 | 0.907 | 0.938 | 0.970 | |

| 53 | 3.135 | 3.203 | 3.272 | 90 | 0.879 | 0.909 | 0.941 | |

| 54 | 3.019 | 3.085 | 3.153 | 91 | 0.852 | 0.882 | 0.912 | |

| 55 | 2.907 | 2.973 | 3.039 | 92 | 0.826 | 0.855 | 0.885 | |

| 56 | 2.801 | 2.865 | 2.930 | 93 | 0.801 | 0.829 | 0.859 | |

| 57 | 2.699 | 2.761 | 2.825 | 94 | 0.777 | 0.805 | 0.833 | |

| 58 | 2.601 | 2.662 | 2.724 | 95 | 0.753 | 0.781 | 0.809 | |

| 59 | 2.507 | 2.567 | 2.628 | 96 | 0.731 | 0.758 | 0.785 | |

| 60 | 2.417 | 2.476 | 2.535 | 97 | 0.709 | 0.735 | 0.762 | |

| 61 | 2.330 | 2.388 | 2.447 | 98 | 0.688 | 0.714 | 0.740 | |

| 62 | 2.248 | 2.304 | 2.361 | 99 | 0.668 | 0.693 | 0.719 | |

| 63 | 2.168 | 2.223 | 2.280 | 100 | 0.648 | 0.673 | 0.698 | |

| 64 | 2.092 | 2.146 | 2.201 | 101 | 0.629 | 0.653 | 0.678 | |

| 65 | 2.019 | 2.072 | 2.126 | 102 | 0.611 | 0.635 | 0.659 | |

| 66 | 1.949 | 2.000 | 2.053 | 103 | 0.593 | 0.616 | 0.640 | |

What is the floor sensor probe and how does it work?

Every aolittel electric underfloor heating thermostat should be configured to use an in-floor sensor probe to monitor the temperature of the floor. This is the most accurate way to control the running temperatures and positively influence your energy bills.

The sensor probe is 3m long, 4mm thick and should be laid within a conduit, in a groove in the floor or insulation board. You can extend the sensor cable (using a 0.75mm twin core flex) by up to 50m.

The conduit has a diameter of 11mm and should be used to facilitate removal or replacement if required.

Sensor probes should always be installed in a clear area of the floor (internal doorways are a good spot) away from any other hot or cold influence such as hot water pipes or large glazed elevations and never under a rug! Rugs act as an insulator, keeping the heat in the floor and raising the temperature.

If you cover the sensor probe with a rug the rest of the floor will stay cold because the thermostat is only monitoring the hottest part of the floor.

The actual sensor is inside the module on the end of the cable and works by constantly monitoring the temperature of the floor.

The temperature data is sent back to the thermostat which, when working to a preset schedule, automatically maintains your desired floor temperature.

3 Tips for Installing a Floor Sensor