Zhengzhou Annec Industrial Co., Ltd. |

|

Verified Suppliers

|

|

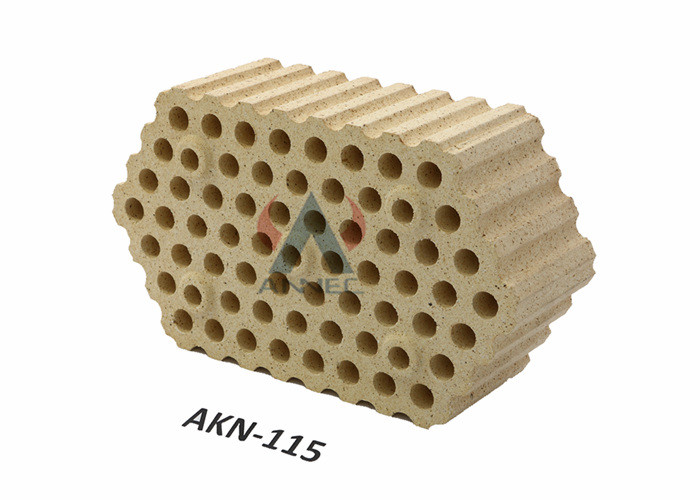

Low Residual Quartz SiO2 Aluminum Silicate Refractory Brick

Definition:

Alumina-Silica Refactory Brick also known as silicon insulation brick. Light refractories with silica content over 91% and bulk density below 1.2g/cm3. The refractoriness and load softening temperature are similar to those of common silica brick. However, due to many pores, the compressive strength, slag resistance and corrosion resistance are not as good as those of ordinary silica brick, while the thermal shock resistance is improved.

Using fine silica as raw material, the critical particle size is usually not more than 1mm, and the particle size less than 0.5mm is not less than 90%. A porous structure is formed by adding inflammable substances into the ingredients or gas generation method, and is made by firing. It can also be made into unburned products. It is mainly used in various parts of the kiln which require heat insulation or reduce the self weight without direct contact with the melt, without the action of aggressive gas and without the rapid change of temperature. When used at high temperature, it shall not contact with basic refractories. According to different materials, the maximum operating temperature is 1200-1550 ℃.

The Alumina-Silica Refactory Brick is mainly an acid refractory material composed of scale quartz, calcite and a small amount of residual quartz and glass phase.

Advantage:

1. Silicon oxide is above 95%.

2. Good acid erosion resistance.

3. High softening point with temperature.

4. No shrink in burn repeatedly.

5. Temperature of refractoriness under load is above 1650º C.

Alumina-Silica Refactory Brick has better thermal conductivity than clay brick and high aluminum brick

Application:

Alumina-Silica Refactory Brick is mainly used for the partition of coking chamber and combustor of coke making furnace, regenerator chamber and cinder chamber of steelmaking open hearth furnace, soaking pit, refractory material of glass melting furnace and sintering furnace of ceramics and other kiln vault and other load-bearing parts.

It is also used for high temperature load bearing parts of hot blast furnace and acid open hearth furnace top.

Product Description:

| Alumina-Silica Refactory Brick | |||||||

| Item | Unit | BG-96A | BG-96B | BG-95 | XBG-96 | ZBG-96 | ZBG-96 |

| SiO2 | % | ≥96 | ≥96 | ≥95 | ≥96 | ≥96 | ≥96 |

| Fe2O3 | % | ≤0.6 | ≤0.8 | ≤1.0 | ≤0.8 | ≤0.8 | ≤0.8 |

| Melt index | % | ≤0.5 | ≤0.7 | - | ≤0.5 | ≤0.5 | ≤0.7 |

| Apparent Porosity | % | ≤21 | ≤22 | ≤22 | ≤21 | ≤21 | ≤22 |

| Ture Bulk Density | g/cm3 | ≤2.34 | ≤2.34 | ≤2.34 | ≤2.34 | ≤2.34 | ≤2.34 |

| Cold Crushing Strength | Mpa | ≥40 | ≥35 | ≥30 | ≥35 | ≥30 | ≥35 |

| Residual Quartz | % | ≤3 | ≤3 | ≤3 | - | - | - |

| Refractoriness under load, 0.2MPa | ℃ | ≥1680 | ≥1680 | ≥1680 | ≥1680 | ≥1680 | ≥1680 |

| Linear Change on Reheating(1450℃×2h) | % | 0~0.2 | 0~0.2 | 0~0.2 | +0.2 | +0.2 | +0.2 |

Why choose us

Q: Are you trading company or manufacturer?

A: We are Manufacturer of refractory materials that have 4 plants in China; So we can provide you with high quality products at more competitive prices. we can provide you professional solutions about your problems. Although our salesman cannot reply you immediately, pls leave your email or phone number, we can let our technician directly help you ASAP.

Q: Do you accept OEM?

A: Sure, we can do OEM for much kind of brick.

Q: What information do we need to provide?

A: If you are clear about the products you purchased, please send us the brick drawings, index(include chemical and physical indicators )and order quantity.

If you are not familiar with it, please tell us the usage and working temperature, we will recommend the product to you.

Q: How long is delivery time?

A: The delivery time will be determined according to the quantity of the order. Our monthly output is 12000tons. We have good connection with shipping company, agency, as well as the local custom and port authority. making sure we deliver on time.

Q: When can I get the price?

A: We usually quote within 24 hours after getting your detailed requirements, like size, quantity etc. If it is an urgent order, you can call us directly.

Q:What is the HS code?

A:The HS code is 69022000.

Q:Is there any cost for the sample?

A: We provide free sample(Less 3 pcs) but don't bear the freight.

Q: What is the Warranty for the fire brick?

A: For all the brick, we have 1 years warranty. If any quality problems on our side occurred in this period, we will take on the shipping cost and replacement.

What you will get from us is our best profession in service and the hospitality that you are willing to become our Friend.

So choosing us is the right choice for you. If you are interested in our products or if you have any question, pls feel free to contact us at any time. We will reply as soon as possible.