LUOYANG MONTON BEARING SCIENCE & TECHNOLOGY CO.,LTD. |

|

| KAH-14 encoder Specification parameter | |||||||

| Series | KAH-14 | ||||||

| Model KAH-14 | 14A | 14B | 14C | ||||

| Deceleration ratio | 1:51 | 1:81 | 1:101 | ||||

| Maximum torque starting &stopping(N·M) | 69 | 91 | 102 | ||||

| Instantaneous maximum torque(N·M) | 42 | 58 | 61 | ||||

| AC voltage 220VAC | Maximum speed | RPM | 119.6 | 75.3 | 60.4 | ||

| Rated speed | RPM | 60.8 | 38.3 | 30.7 | |||

| Maximum current | Arms | 4.53 | 3.89 | 3.41 | |||

| Rated current | Arms | 2.12 | 1.85 | 1.56 | |||

| Torque constant | N·M/Arms | 19.81 | 31.35 | 39.10 | |||

| Motor phase resistance | Ohms | 2.135 | |||||

| Motor phase inductance | mH | 3.869 | |||||

| Motor Back EMF | Vrms/kRPM | 30.66 | |||||

| AC voltage 1100VAC | Maximum speed | RPM | 100 | 63.0 | 50.5 | ||

| Rated speed | RPM | 60.8 | 38.3 | 30.7 | |||

| Maximum current | Arms | 9.49 | 7.87 | 7.08 | |||

| Rated current | Arms | 4.28 | 3.72 | 3.14 | |||

| Torque constant | N·M/Arms | 9.82 | 15.61 | 19.45 | |||

| Motor phase resistance | Ohms | 1.036 | |||||

| Motor phase inductance | mH | 1.684 | |||||

| Motor Back EMF | Vrms/kRPM | 14.79 | |||||

| AC voltage 480VAC | Maximum speed | RPM | 78.4 | 49.4 | 39.6 | ||

| Rated speed | RPM | 60.8 | 38.3 | 30.7 | |||

| Maximum current | Arms | 17.89 | 18.86 | 13.33 | |||

| Rated current | Arms | 10.88 | 12.03 | 7.97 | |||

| Torque constant | N·M/Arms | 3.86 | 4.82 | 7.65 | |||

| Motor phase resistance | Ohms | 0.262 | |||||

| Motor phase inductance | mH | 0.313 | |||||

| Motor Back EMF | Vrms/kRPM | 7.98 | |||||

| Absolute Encoder | Encoder Type | Hollow absolute multiturn encoders ,Single-loop 19,22or24, multiturn16 | |||||

| Encoder resolution Motor(1time)rotation | 219(524,288),222(4,194.304)or224(16777216) | ||||||

| Motor multiple rotation counter | 215(65.536) | ||||||

| Incremental | Encoder resolution | Hollow incremental encoder,40000impulse/rpm(4 time signal) | |||||

| encoder | Output shaft resolution | pulse/rev | 2040000 | 3240000 | 4040000 | ||

| uniderection positioning accuracy | Arc Sec | 60 | 40 | 40 | |||

| Bidirectional positioning accuracy | Arc Min | 2 | 1.5 | 1 | |||

| Overturning stiffness | ×104 N·m /rad | 22.5 | 27.3 | ||||

| Torsional stiffness | ×104 N·m /rad | 1.8 | 2.3 | ||||

| Moment of inertia | without Brake | Kg*m2 | 0.19 | 0.57 | 0.86 | ||

| with Brake | Kg*m2 | 0.22 | 0.63 | 0.95 | |||

| Weight | without Brake | Kg | 2.2 | ||||

| with Brake | Kg | 2.5 | |||||

| Motor Grade | 16 | ||||||

| Motor insulation | Heat resistance grade :F(155℃) | ||||||

| Insulation resistance:above200MΩ(DC500V) | |||||||

| Dielectric Strength:AC1500V/1min | |||||||

| Protection grade | Fully closed self cooling type(IP65/IP67 degree) | ||||||

Main Features

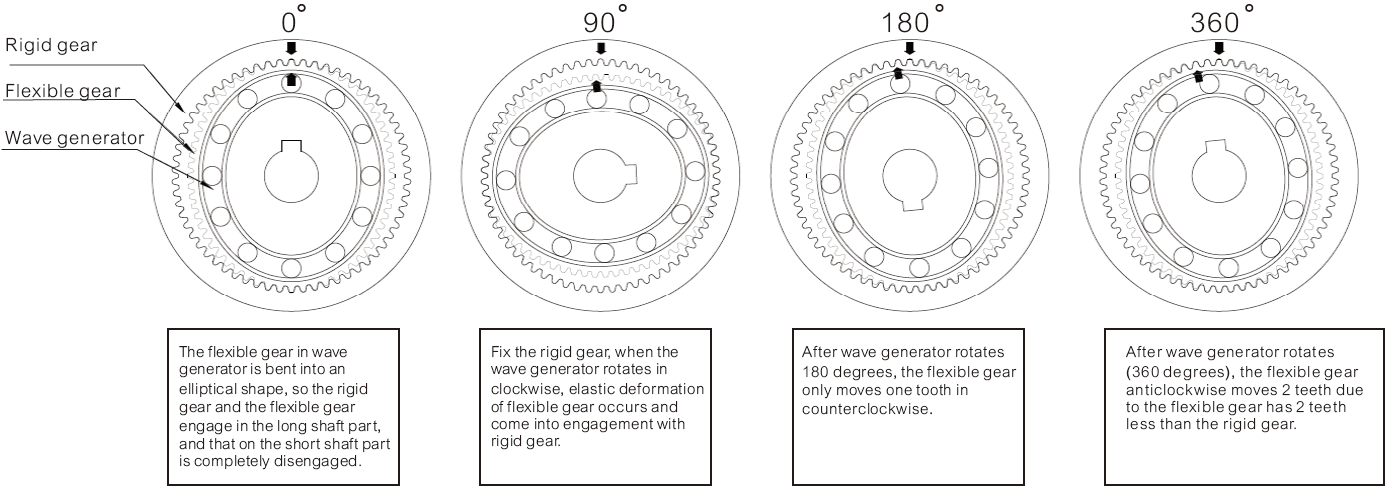

1. KAH series hollow shaft rotary actuator provides large-torque

and high-precision rotary actuation. With integrated design,

processing and assembly technique, it is provided with high

precision harmonic drive reducer, frame-less torque motor, hollow

shaft high resolution absolute encoder, brake and intelligent

sensor.

2. It provides high torque output and high torque density, for

example, the torque of KAH-40 rotary actuator can reach 800N·m.

The positioning precision of rotary actuator is within 30 Arc sec.

3.An internal through-hole is set to facilitate threading of wires,

gas pipe and laser beams, which simplify the system structure.

4.Dozens of product models are provided to meet diversified needs,

and the products with 220 VAC, 110VAC and 48 VAC voltages are

available.

5.High protection grade (IP67) makes the product applicable to

severe working environment.

6. It can be used by matching with KDE series EtherCAT Bus Servo

Drivers to realize ultra-low vibration control and reliable stable

operation, through which offers an integrated drive control

solution to customers.

Models of KAH series Hollow Shaft Rotary Actuators can be offered

as below:

KAH-14, KAH-17, KAH-20, KAH-25, KAH-32, KAH-40.

Please contact with us for more infotmation.