LUOYANG MONTON BEARING SCIENCE & TECHNOLOGY CO.,LTD. |

|

Features:

YRT precision rotary table bearing is a kind of bearing fixed by a

bidirectional thrust bearing and a centripetal-guided bearing. They

can support radial loads, axial loads from both directions and

tilting moments free from clearance and are particularly suitable

for bearing arrangements with high requirements for running

accuracy,like rotary tables, millings heads and reversible

clamps.Due to the fixing holes in the bearing rings, the units are

very easy to fit.

The bearings are radially and axially preloaded after fitting.

Sealing/Lubricant:

YRT bearings are supplied with seals. YRT bearings are greased by a

lithium complex soap grease and can be lubricated via the outer

ring and L-section ring.

Operating temperature:

YRT bearings are suitable for operating temperatures from 30℃ to

120℃

Design and safety guidelines:

Basic rating life:

Please contact us in relation to checking of the basic rating life

.The speed ,load and operating duration must be given.

Static load safety factor: The static load safety factor S0 indicates the security against

impermissible permanent deformations in the bearing. It is

determined as follows:

The static load safety factor S0 indicates the security against

impermissible permanent deformations in the bearing. It is

determined as follows:

Static load safety factor :Cor Coa N

Basic static load rating according to dimension tables: For Foa N

Maximum static load on the radial or axial bearing.

Caution! In machine tools and similar areas of application, S0

should be >4

Limiting speeds:

The bearings allow the limiting speeds given in the dimension

tables. The operating temperatures occurring are heavily dependent

on the environmental conditions. Calculation is possible by means

of a thermal balance analysis based on frictional torque data.

Frictional torque:

The bearing frictional torque MRL is influenced primarily by the

viscosity and quantity of the lubricant and the bearing preload.

The lubricant viscosity and quantity are dependent on the lubricant

grade and operating temperature. The bearing preload is dependent

on the mounting fits, the geometrical accuracy of the adjacent

parts, the temperature difference between the inner and outer ring,

the screw tightening torque and the mounting situation.

Starting torque:

For YRT bearing, it must be taken into consideration that the

frictional torque can increase by a factor of between 2 and 2.5

with increasing speed.

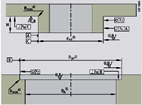

Accuracy of adjacent construction:

The adjacent construction should be produced in accordance with

Figure and the tolerances must be in accordance with the tables

starting on page. Any deviations will influence the bearing

frictional torque ,running accuracy and running characteristics.

Legend to Figure:

1.Support over whole bearing height. It must be ensured that the

means of support has adequate rigidity.

2.A precise fit is only necessary if radial support due to the load

or a precise bearing position is required.

3.Note the bearing diameter D1 according to the dimension tables.

Ensure that there is sufficient distance between the rotating

bearing rings and the adjacent construction.

Geometrical and positional accuracy of the adjacent construction:

| nominal shaft diameter d mm | Deviation d | Roundness Parallelism Perpendicularity t2,t2,t8, | ||

| over | incl. | for tolerance h5 µm | µm | |

| 50 | 80 | 0 | -13 | 3 |

| 80 | 120 | 0 | -15 | 4 |

| 120 | 150 | 0 | -18 | 5 |

| 150 | 180 | 0 | -18 | 5 |

| 180 | 250 | 0 | -20 | 7 |

| 250 | 315 | 0 | -23 | 8 |

| 315 | 400 | 0 | -25 | 9 |

| 400 | 500 | 0 | -27 | 10 |

| 500 | 630 | 0 | -28 | 11 |

| 630 | 800 | 0 | -32 | 12 |

| 800 | 1000 | 0 | -36 | 14 |

| nominal shaft diameter D mm | Deviation D | Roundness Parallelism Perpendicularity t2,t2,t8, | ||

| over | incl. | for tolerance zone h5 µm | µm | |

| 120 | 150 | +18 | -7 | 5 |

| 150 | 180 | +18 | -7 | 5 |

| 180 | 250 | +22 | -7 | 7 |

| 250 | 315 | +25 | -7 | 8 |

| 315 | 400 | +29 | -7 | 9 |

| 400 | 500 | +33 | -7 | 10 |

| 500 | 630 | +34 | -7 | 11 |

| 630 | 800 | +38 | -8 | 12 |

| 800 | 1000 | +44 | -12 | 14 |

| 1000 | 1250 | +52 | -14 | 16 |

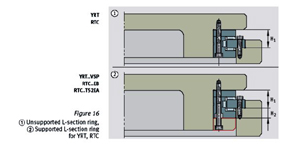

Mounting dimensions H1,H2

L-section ring without support ring:

For the case “L-section ring without support ring”, the bearing

designation is :YRT

L-section ring with support ring:YRT bore diameter VSP

For the case “L-section ring with support ring”, the bearing

designation is :YRT VSP

Caution! For bearing arrangements with a supported L-section ring ,

only bearings with the suffix VSP,EB or T52EA can be ordered. If

the normal design is mounted with a supported L-section ring, there

will be a considerable increase in the bearing frictional torque

.The support ring should be at least twice as the shaft locating

washer of the bearing.

Fitting:

Retaining screws secure the bearing components during transport,

For easier centring of the bearing ,the screws should be loosened

before fitting and either secured again or removed after fitting.

Tighten the fixing screws in crosswise sequence by using a torque

wrench in three stages to the specified tightening torque MA,

rotating the bearing:

Stage 1 40% of MA

Stage 2 70% of MA

Stage 3 100% of MA

Observe the correct grade of the fixing screws.

Caution! Mounting forces must only be applied to the bearing ring

to be fitted, never through the rolling elements. Bearing

components must not be separated or interchanged during fitting and

dismantling. If the bearing is unusually difficult to move ,loosen

the fixing screws and tighten them again in steps with a crosswise

sequence. This will eliminate any distortion. Bearings should only

be fitted in accordance with ,Fitting and Maintenance Manual.

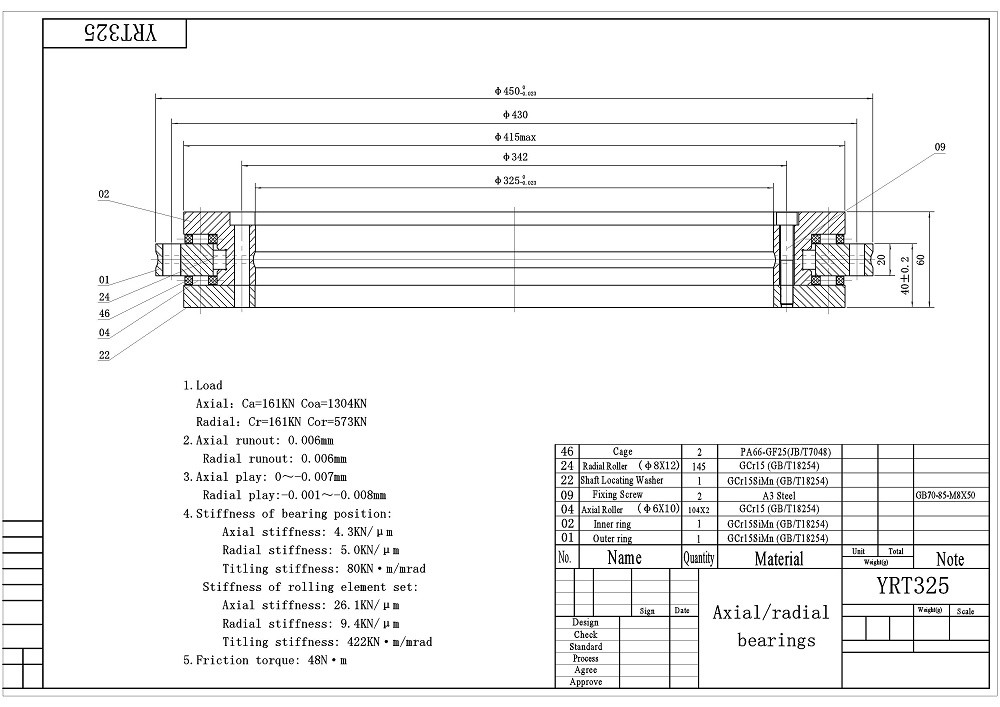

YRT Dimensional tolerances, mounting dimensions, axial and radial runout YRT

| Dimensional tolerance | Mounting dimensions | Axial and radial runout | ||||||||

| Bore | Outside diameter | H1 mm | ΔH1s mm | Restr- icted ΔH1s mm | H1 mm | Restr- icted ΔH1s mm | Stan- dart µm | Restri- cted µm | ||

| d mm | Δds mm | D mm | ΔDs mm | |||||||

| 50 | -0.008 | 126 | -0.011 | 20 | ±0.125 | ±0.025 | 10 | ±0.02 | 2 | 1 |

| 80 | -0.009 | 146 | -0.011 | 23.35 | ±0.15 | ±0.025 | 11.7 | ±0.02 | 3 | 1.5 |

| 100 | -0.01 | 185 | -0.015 | 25 | ±0.175 | ±0.025 | 13 | ±0.02 | 3 | 1.5 |

| 120 | -0.01 | 210 | -0.015 | 26 | ±0.175 | ±0.03 | 14 | ±0.02 | 3 | 1.5 |

| 150 | -0.013 | 240 | -0.015 | 26 | ±0.175 | ±0.03 | 14 | ±0.02 | 3 | 1.5 |

| 180 | -0.013 | 280 | -0.018 | 29 | ±0.175 | ±0.03 | 14 | ±0.025 | 4 | 2 |

| 200 | -0.015 | 300 | -0.018 | 30 | ±0.175 | ±0.04 | 15 | ±0.025 | 4 | 2 |

| 260 | -0.018 | 385 | -0.02 | 36.5 | ±0.2 | ±0.05 | 18.5 | ±0.025 | 6 | 3 |

| 325 | -0.023 | 450 | -0.023 | 40 | ±0.2 | ±0.05 | 20 | ±0.025 | 6 | 3 |

| 395 | -0.023 | 525 | -0.028 | 42.5 | ±0.2 | ±0.05 | 22.5 | ±0.025 | 6 | 3 |

| 460 | -0.023 | 600 | -0.028 | 46 | ±0.225 | ±0.06 | 24 | ±0.03 | 6 | 53 |

| 580 | -0.025 | 750 | -0.035 | 60 | ±0.25 | ±0.075 | 30 | ±0.03 | 10 | 53 |

| 650 | -0.038 | 870 | -0.05 | 78 | ±0.25 | ±0.1 | 44 | ±0.03 | 10 | 53 |

| 852 | -0.05 | 1095 | -0.063 | 80.5 | ±0.3 | ±0.12 | 43.5 | ±0.03 | 12 | 63 |

| 950 | -0.05 | 1200 | -0.063 | 86 | ±0.3 | ±0.12 | 46 | ±0.03 | 12 | 63 |

| 1030 | -0.063 | 1300 | -0.08 | 92.5 | ±0.3 | ±0.15 | 52.5 | ±0.03 | 12 | 63 |

For rotating inner and outer ring,measured on fitted bearing, with

ideal adjacent construction.

Special design,YRT only.

By agreement only for rotating outer ring.

| Dimensional tolerance | Mounting dimensions | Axial and radial runoutµm | |||||

| Bore | Outside diameter | H1 mm | ΔH1s mm | H2 mm | |||

| d mm | Δds mm | D mm | ΔDs mm | ||||

| 200 | -0.015 | 300 | -0.018 | 30 | +0.04 -0.06 | 15 | 4 |

| 260 | -0.018 | 385 | -0.02 | 36.5 | +0.05 -0.07 | 18.5 | 6 |

| 325 | -0.023 | 450 | -0.023 | 40 | +0.06 -0.07 | 20 | 6 |

| 395 | -0.023 | 525 | -0.028 | 42.5 | +0.06 -0.07 | 22.5 | 6 |

| 460 | -0.023 | 600 | -0.028 | 46 | +0.07 -0.08 | 24 | 6 |

For rotating inner and outer ring,measured on fitted bearing, with ideal adjacent construction.

Special design:

For YRT, axial and radial runout tolerances reduced by 50%,

Additional text: axial/radial runout 50%

For YRT, loser tolerance on mounting dimensions H1 and H2.

Additional text:H1 with tolerance±…; H2 with tolerance.