Anping Anao Mesh And Metal Products Co., Ltd. |

|

900mm Width PLC Control Metal Rib Lath Machine With Material Thickness 0.3mm

Introduction:

Metal rib lath machine is used for produce metal rib lath.Rib lath machine's working process: De-coil → punching → expanding and shearing → Rib lath feed out.

The full production line includes the following equipments:Decoiler,main punching machine,expanding machine,collect table.

1. Decoiler: Using speed adjustable motor, in order to cooperate with the punching machine feeding speed, recoiler speed can be adjusted, feeding speed a little faster than punching machine. When the steel material accumulated a certain amount, recoiler stops working, when the steel material use surplus to a certain amount, recoiler restart feeding material.

2. Punching machine: feeding traction by stepper motor, it can achieve feeding smooth and steady and high accuracy.

3. Expanding machine: adopt chain drive, effectively solve the influence of upper shaft to drive. Using multi-stage expansion gradually open the mesh hole. Multi-stage expansion can make the hole size very uniform, reduced the traction and expansion force, and reduced the overall load.Multistage pressing wheels ahead, multistage leveling rollers behind; made the rib lath product straight, improve product quality.Then cutting part consists of hydraulic pressure station, cutting dies and automatic control part. When expanding machine start working, hydraulic pressure station keep pressure status, when rib lath finished product reach 2500MM length, expanding machine stop working and cutting part cut the rib lath, then return quickly, expanding machine start working again.

4. Collecting table: Rib lath after cutting fall on the collecting table.

Technical parameter:

| Rib lath production line | ||

| Rib lath width | 900mm | |

| Material thickness | 0.3-0.33mm | |

| Rib deep | 9mm | |

| Rib distance | 100mm | |

| Mesh hole size | 12*7mm | |

| Productivity | 32 sheets/hour | |

Application:

Rib lath is idea for refurbishing damaged or aged masonry walls, when a key for rendering is not certain due to disintegration or softening of the wall face.

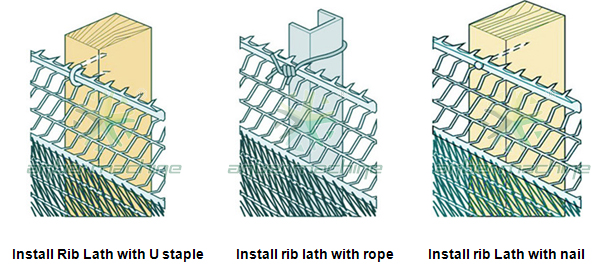

Lath should be fixed with apexes of ribs against the wall, edge ribs of sheets nesting into each other should be wire-tied every 15cm and ends of sheets should be lapped not less than 2.5cm and nesting ribs securely tied together. Stainless steel fixing should be used at sufficient intervals to hold the lath firmly in position.

Application photo from our customer: