Anping Anao Mesh And Metal Products Co., Ltd. |

|

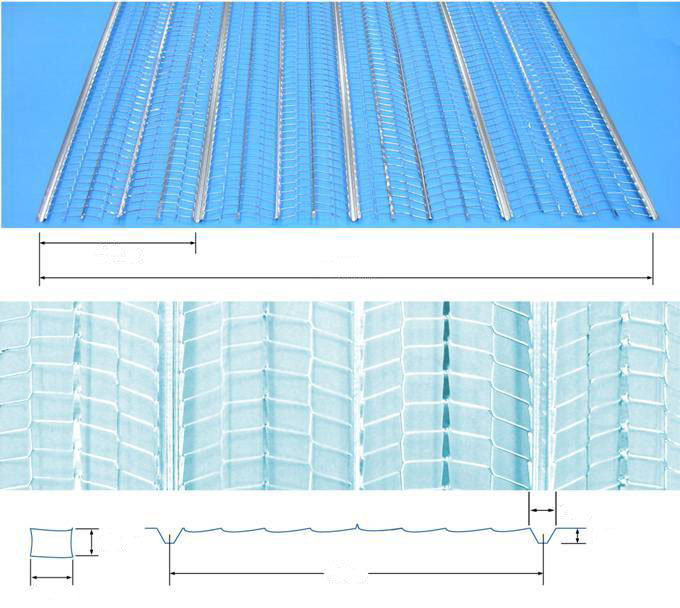

600mm Width Automatic Rib Lath Production Line For Rib Lath Production

Rib lath production line including decoiler, main punching machine, expanding machine, collecting table, electric control cabinet. Rib lath production line specialized in producing metal rib lath,with features of high production efficiency(produce 80.46m per hour),less waste materials,low cost,stable property,etc.

RIB LATH:

Technical parameter:

| Rib lath production line | ||

| Rib lath width | 600mm | |

| Material thickness | 0.3-0.33mm | |

| Rib deep | 9mm | |

| Rib distance | 100mm | |

| Mesh hole size | 12*7mm | |

| Total Weight | 9000KG | |

| Productivity | 32 sheets/hour | |

Rib lath production line detailed introduction:

Decoiler adopts adjustable-speed motor,in order to matching the feeding speed of the main punching machine can be adjusted arbitrarily.It should be decoiler speed slightly faster than main punching machine speed.When steel material accumulate to a certain amount,decoiler stop working.When the accumulated steel material using to a certain residual quantity,decoiler start working again.

Main punching machine feeding material by step motor.It can achieve feeding smoothly,size more nicety,high accuracy,good reliability,can meet the technical requirements of the product.

Expanding machine adopt chain drive and multistage expansion,gradually expanding the mesh,improve the uniformity of the mesh.Forepart adopt multistage pressing rollers,posterior adopt multistage leveling rollers,and then can achieve straightness,improve the quality of products.At the end of expanding machine install cutting device.Cutting device composed of hydraulic pressure station,cutting mould and automatic control section.

Mesh after cutting fall to the tray of collecting table,after turn the tray of collecting table,mesh fall to the conveyer belt of collecting table. Mesh transported to the manual roller table by conveyer belt,collected by workers then taking down and packing.