Shanghai Tankii Alloy Material Co.,Ltd |

|

Verified Suppliers

|

|

High Purity Electrolytic Nickel Foil 0.025mm Mirror Finished Surface

Electrodeposited nickel foil is produced by dissolving nickel ions in solution and, by a process based on electrolysis, these ions are subsequently deposited on to a rotating metallic mandrel to form a layer of high purity nickel foil. Through this method of manufacture, pure nickel foil can be supplied in greater widths when compared with conventional cold rolling of metal foil. Surface finish is excellent and can be used as an alternative to its cold rolled cousin, especially for those applications that require very thin foils and in wider widths. Due to the method of manufacture, small quantities can be produced to customer specification, with samples easily obtainable. Thickness tolerances are very tightly controlled to produce a very consistent and high quality product.

A pre-cleaning and an electroless nickel plating (EN-HP) were applied to copper foil to improve its tribological behaviour and corrosion resistance. The coating porosity was measured by the corrodkote, tribological behaviour was measured with microhardness tester and a CSM ball-on-disk tribometer, corrosion resistance was measured by potentiodynamic polarization in 3.5 wt.% NaCl solution. Matte nickel plating (mNi) and moderate compact Ni–P coating (EN-MP) were made as comparisons to EN-HP in those tests. By deposition of EN-HP, both coating porosity and tribological behaviour are greatly improved compared to mNi, and the corrosion resistance is distinctly ameliorated to the comparisons. Above research demonstrates that the copper foil with EN-HP coating is good underlay in assemblage of machine.

During discharge, lithium ions (Li+) carry the current within the battery from the negative to the positive electrode, through the non-aqueous electrolyte and separator diaphragm.

During charging, an external electrical power source (the charging circuit) applies an over-voltage (a higher voltage than the battery produces, of the same polarity), forcing a charging current to flow within the battery from the positive to the negative electrode, i.e. in the reverse direction of a discharge current under normal conditions. The lithium ions then migrate from the positive to the negative electrode, where they become embedded in the porous electrode material in a process known as intercalation.

Name | Nickel foil |

Material | Ni200, Ni201 |

Color | bright, oxidized |

Size | Dia 0.025mm-0.6mm Coil / Straight/Spool |

Standard | ASTM B880-1988 |

Surface | Polished |

Standard | ASTM B160/B162, AISI,DIN,GB etc |

Application | Electric apparatus, chemical, heating etc. |

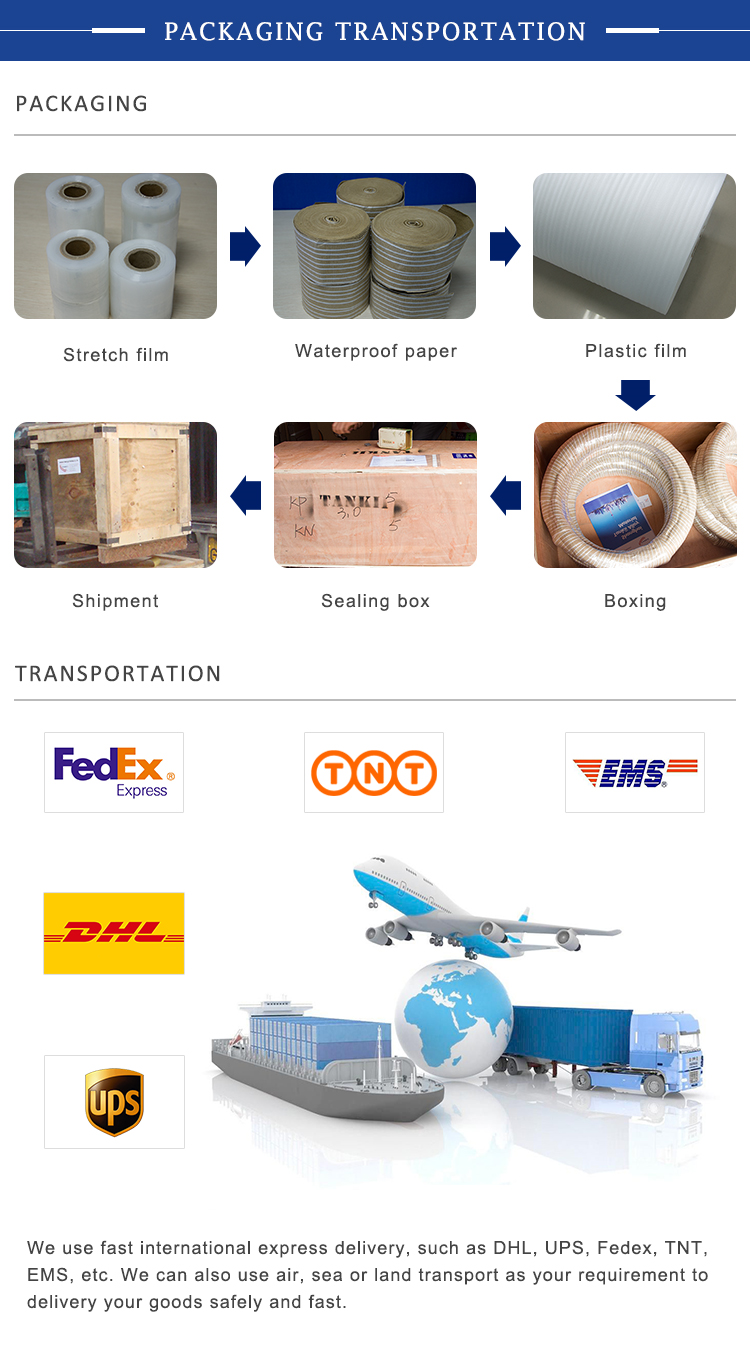

Package | Carton or wooden case as demanded |

Sample | All in stock |

Certification | Official Quality Certification and test report. |

A pre-cleaning and an electroless nickel plating (EN-HP) were applied to copper foil to improve its triboloed to mNi, and the corrosion resistance is distinctly ameliorated to the comparisons. Above research demonstrates that the copper foil with EN-HP coating is good underlay in assemblage of machine.

gical behaviour and corrosion resistance. The coating porosity was measured by the corrodkote, tribological behaviour was measured with microhardness tester and a CSM ball-on-disk tribometer, corrosion resistance was measured by potentiodynamic polarization in 3.5 wt.% NaCl solution. Matte nickel plating (mNi) and moderate compact Ni–P coating (EN-MP) were made as comparisons to EN-HP in those tests. By deposition of EN-HP, both coating porosity and tribological behaviour are greatly improved comparA pre-cleaning and an electroless nickel plating (EN-HP) were applied to copper foil to improve its tribological behaviour and corrosion resistance. The coating porosity was measured by the corrodkote, tribological behaviour was measured with microhardness tester and a CSM ball-on-disk tribometer, corrosion resistance was measured by potentiodynamic polarization in 3.5 wt.% NaCl solution. Matte nickel plating (mNi) and moderate compact Ni–P coating (EN-MP) were made as comparisons to EN-HP in those tests. By deposition of EN-HP, both coating porosity and tribological behaviour are greatly improved compared to mNi, and the corrosion resistance is distinctly ameliorated to the comparisons. Above research demonstrates that the copper foil with EN-HP coating is good underlay in assemblage of machine.