Dome Metals Co., Ltd. |

|

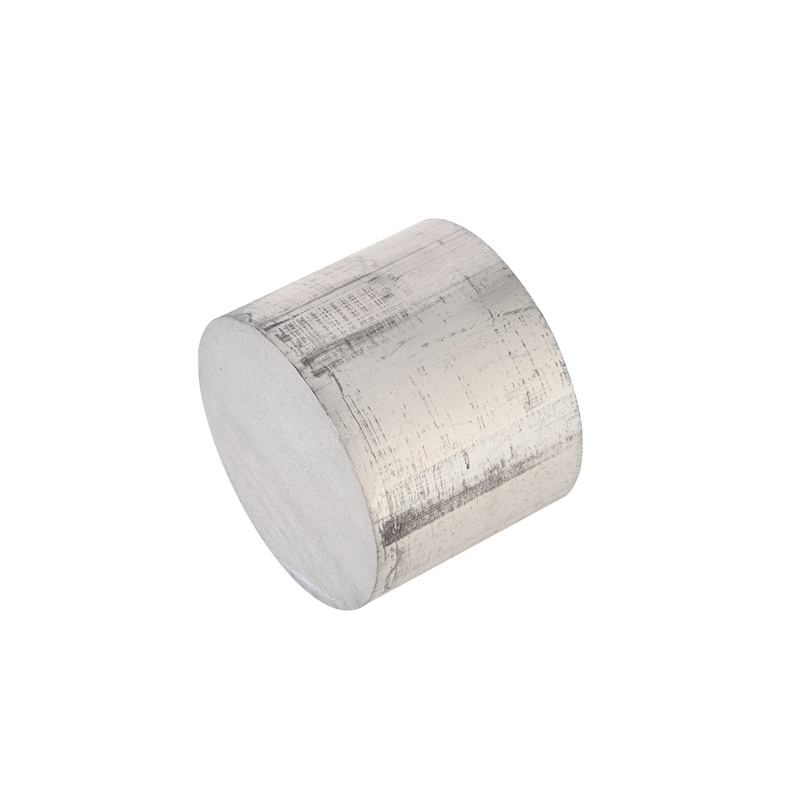

Aerospace 95% AZ31 Magnesium Alloy Rod Semi Continuous Casting

Application of Magnesium Alloy Rod

Magnesium Alloy Rod for Concrete Tools, Construction, Recreation Products, LED lamps, Bicycle Tubesand Pipes, Wheelchairs, medical equipment, fitness equipment etc. It is the lightest in the practical metal, high strength, high rigidity, and also has Good shock absorption performance.

Magnesium Alloy Chemical composition:

| Alloy Element | Type | Chemical Composition% | Other elements b | ||||||||||||

| Mg | Al | Zn | Mn | Ce | Zr | Si | Fe | Ca | Cu | Ni | Be | Sub-total | total | ||

| MgAlZn | AZ31B | Balance | 2.5-3.5 | 0.6-1.4 | 0.1-0.2 | --- | --- | ≦0.08 | ≦0.003 | ≦0.04 | ≦0.01 | ≦0.001 | --- | ≦0.05 | ≦0.30 |

| AZ40M | Balance | 3.0-4.0 | 0.2-0.8 | 0.15-0.5 | --- | --- | ≦0.10 | ≦0.05 | --- | ≦0.05 | ≦0.005 | ≦0.01 | ≦0.01 | ≦0.30 | |

| AZ80A | Balance | 7.8-9.2 | 0.2-0.8 | 0.12-0.5 | --- | --- | ≦0.10 | ≦0.005 | --- | ≦0.05 | ≦0.005 | --- | --- | ≦0.30 | |

| AZ91D | Balance | 8.5-9.5 | 0.45-0.9 | 0.17-0.4 | --- | --- | ≦0.08 | ≦0.004 | --- | ≦0.025 | ≦0.001 | 0.0005- 0.003 | ≦0.01 | ≦0.30 | |

| MgMn | M2M | Balance | ≦0.20 | ≦0.30 | 1.3-2.5 | --- | --- | ≦0.10 | ≦0.05 | --- | ≦0.05 | ≦0.007 | ≦0.01 | ≦0.01 | ≦0.20 |

| MgZnZr | ZK61M | Balance | ≦0.05 | 5.0-6.0 | ≦0.10 | --- | 0.3-0.9 | ≦0.05 | ≦0.05 | --- | ≦0.05 | ≦0.005 | ≦0.01 | ≦0.01 | ≦0.30 |

| MgMnRe | ME20M | Balance | ≦0.20 | ≦0.30 | 1.32-2.2 | 0.15-0.35 | --- | ≦0.10 | ≦0.05 | --- | ≦0.05 | ≦0.007 | ≦0.01 | ≦0.01 | ≦0.30 |

Compared with conventional casting magnesium alloys,

semi-continuous casting magnesium alloys are finer in the

organization, more uniform on the ingredients, and more compact

inside with higher strength and elongation.

1. By pipetting and secondary refining, the Mg alloys have high

purity and low impurity. The magnesium liquid pouring directly from

the heat holding furnace crystallize rapidly to improve the

compactness of internal microstructure of the Mg rods. The internal

crystal are more compact , and the physical performance is greatly

enhanced compared to conventional casting products.

2. The flux slag content of finished products tends to zero. Using

the emerging insert gas protective devices, the flux slag content

are greatly reduced and product quality is improved. In traditional

process, the smelting process is completely exposed to the air, and

the flame is retardant only by flux and other flame retardant

materials.

3. Smooth surface. Clean. No porosity, shrinkage or slag.

4. Flexible length. The existing maximum diameter is 600mm. It can

be skinned and cut according to customers' requirements. In

addition, other products with different specifications can be

produced to meet customers needs. We can also produce various

specifications of Mg alloy flat bars by semi-continuous casting.