Anhui Filter Environmental Technology Co.,Ltd. |

|

Verified Suppliers

|

|

Description:

Filter bag are composed by woven filter material bag body, snap ring, clamp, chain hoist, etc. The rest of the filter bag dust collector and its accessories are the venturi tube, frame, mouth of elastic ring, etc.

We are manufacuturer of dust filter bags ,Polyester filter bags, Nomex filter bags ,PPS filter bags ,P84filter bag,PTFE teflon 100% filter bags ,etc.for different industry dust filtration applications.

Specification:

The diameter of the filter bag is 115-200mm, length is 2000 - 9000mm, the specifications of the commonly used filter bag is 120 - 160 mm diameter, 2000 ~ 6000mm length.

fiberglass dust filter bag

The oval, flat, envelope and support ring types of filter bag, please be sure to enquiry for us engineer. We'd like to provide the most suitable design and filtration material select suggestion for your reference.

Technical Data:

| Fibre | PTFE |

| Scrim | PTFE |

| Weight(G/M2) | 750 |

| Thickness (mm) | 1.27 |

| Width (mm) | ≤ 2.2 |

| Length | 50m/roll |

| Finish treatment | Singeing,Calendering,Heat-set,PTFE-coating,Water and Oil Repellent,PTFE membrane Coating. |

| Air permeability (L/dm2*min@200pa): | 5.47 |

| Tensile strength (N/5× 20cm) | Warp:>700 Weft:>600 |

| Tensile elongation (%): | Warp:<30 Weft:<45 |

| Temperature (ºC): | Continue: 240 Instant: 280 |

| Application | Mainly used in Combustion,Coal burning boiler,Waster incineration,Carbon black producing. |

Production Feature:

1. Various material: Polyester(PE), Polypropylen(PP), Aramid, P84,

Acrylic, PPS, Fiberglass, PTFE,Nomex,FMS etc.

2. Strong intensity.

3. Excellent anti-abrasion,good finishing treatment.

4. Good raw material, competitive price.

5. High filtration efficiency .

6. Fast delivery.

7. Size can be customized.

8. Factory manufacturer could contol quality and price.

9. Strict quality inspection and contol.

10. Professional designer team to match with your operating

condition.

Application:

Polyester:

cement,iron and steel industries,wood processing,flour plant

Polypropylene:

Applicable to food,flour,sugar,fertilizer,electroplating and

pesticide industries

PPS:

Applicable to the working conditions with low oxidation gas from

coal-fired boiler,waste incineration,metal smelting and chemical

industries

P84:

working condition with corrosive gas,such as chemical,metal

smelting,waste incineration industries,cement kiln and coal-fired

boiler

Nomex/Aramid:

Applicable to asphalt,non-ferrous metal production,ceramic,glass

industries,kiln in cement factories and blast furnace in steel

factory

PTFE:

Applicable to the working condition with high corrosive gas and

high temperature,such as chemical industry,coal-fired boiler,waste

incineration industry and non-ferrous metal production

Advantages:

1. With high tensile strength and low tensile elongation

2. Applied in continuous temperature 240℃ , works well .

3. As PTFE filter bags, it is largely used in high temperature

environmental.

4. With good air permeability and also can be adjusted by

customers' specific request

5. Being baghouse filter bags, they are installed in baghouse and

with high-efficiency filtration .

Specification:

1. Material :with100% PTFE fiber

2. Scrim: with PTFE staple yarn

3. Finish treatment with singeing, calendering and heat setting.

4. Air permeability (l/m2/s): 150~300

5. Temperature (℃): Continue: 240, Instant: 280

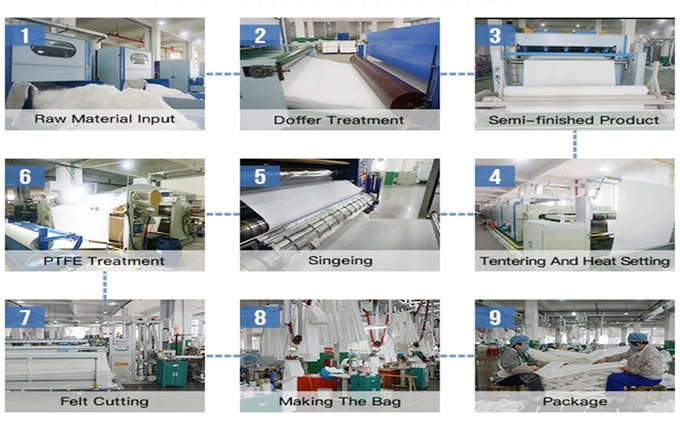

Producing Process:

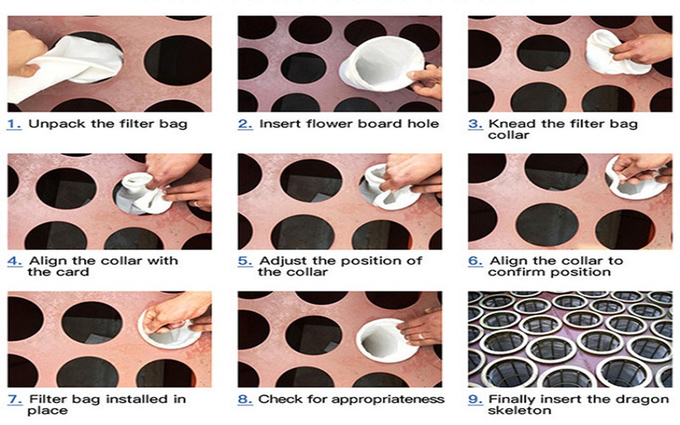

Install Diagram:

Applications:

More Production:

Packaging & Delivery:

Foreign Trade Team:

Exhibization:

Customer Visit:

Certificate:

Shipping Details:

SHIPPING (Normally arrive port time in working days) | ||||

| Destination | Express/Courier | SHIP BY SEA | SHIP BY AIR | SHIP BY EMS |

| DHL/FEDEX/UPS/TNT | ||||

| North America | 3~7 days | 15~24 days | 5~7 days | 10~12 days |

| South America | 3~7 days | 15~25 days | 5~7 days | 10~12 days |

| European Countries | 3~7 days | 20~30 days | 5~7 days | 10~12 days |

| Africa Countries | 3~7 days | 40~50 days | 5~7 days | 10~12 days |

| The Middle East | 3~7 days | 15~25 days | 5~7 days | 10~12 days |

| Australia | 3~7 days | 10~15 days | 5~7 days | 10~12 days |