Changzhou Aidear Refrigeration Technology Co., Ltd. |

|

Guiding Structure Wire Mesh Welding Machine , Automatic Mesh Welding Machine

Specification

| Product name | Guiding Structure Wire Mesh Welding Machine , Automatic Mesh Welding Machine |

| Wire diameter | 8-20mm |

| Wire size | 1*2m,2*4m |

| Welding transformers | 120KVA |

| Welding speed | 40-45times/min |

| Welding hole diameter | 80*80-200*200m |

| Weight | 2200kgs |

| Overall dimension | 2150*2200*1370mm |

| Application | Tunnels ,High-rise floors ,Subway, Power plants |

Description

welding machine+3sets of the welding Jig. (not including the guiding structure and the transfer table)

welding machine is same as Type “A” : 9 pairs of welding electrodes.

Guiding structure ,transfer table and operation platform should be made extra.

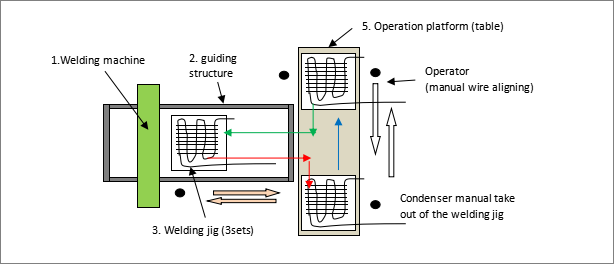

The operation process refer to the draft drawing, 4 operators/machine .

welding forwarding by the guiding jig, but need the manual assist.

Operation process (draft drawing) of this Type

Function features

1. Controlled by computer, the welding current and welding time in

each welding transformer can be individually adjusted. The machine

operator interface with color touch screen and control buttons,

easy to operate.

2. Host framework structure, stable performance, the welding

pressure is continuously adjustable, solid and perfect welding

spot.

3. Integrated deceleration electromagnetic brake motors for power,

inverter control, adjustable speed.

4. Modular design for the upper and lower electrodes, convenient to

adjust the mesh.

5. weft-hopper obtains wires by motor driver devices, electric

magnetic increase feeding device auto-feeding the wefts into the

preparation area of disc device from the large hopper, and the weft

hopper is installed in the removable pull rid, convenient toadjust

and maintain.

6. The mesh pulling part driven by servo motor can be set a variety

of weft space in the same mesh, pull the mesh continuously back and

forth to extend the size of mesh, and use pneumatic clamping device

to accurate weft spacing.

7. The warp feeding part driven by stepper motor can be fed the

warps which a whole mesh needs when welding, so that the machine is

very short interval of time.

8. Automatic CNC steel mesh welding machine is equipped with a mesh

roller frame and removable warp frame.