ShenZhen Vector Technology Co., Ltd. |

|

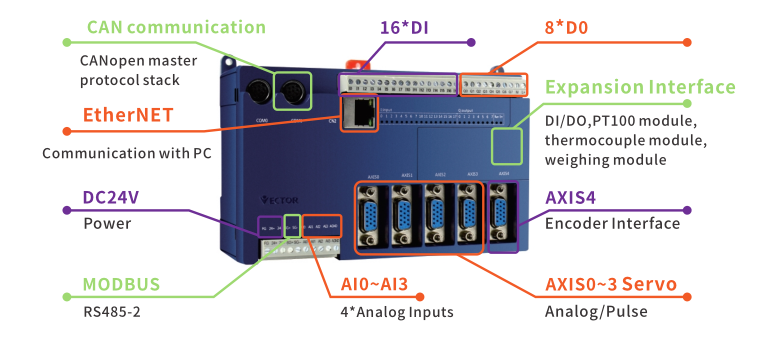

MULTIPROG IEC61131-3 Standard CanOpen 5 Axis Motion Controller For Laminating Equipment

The VA series motion controller uses the MULTIPROG programming tool and supports 5 programming

languages of the IEC61131-3 international standard, making it easy for application programmers to get

started. This motion controller supports three kinds of interfaces: pulse,analog and CanOpen for motion

control. This product is actually the leader in non-bus motion controller products.

Products Features

| Products | Motion Controller For Laminating Equipment |

| Brand | Vector |

| Model No. | VEC-VA-MP-005-MA |

| Axis | 5 Axis |

| Progarmming Tool | MULTIPROG |

| Programming Language | IEC61131-3 |

| Expansion Units | IO Expansion, Digital, Analog, PT100 Thermocouple, Weight |

| Communication Protocols | CAnopen |

Introduction of Software:

Analog mode - Support 4*Servo + 12*Virtual Axis

Pulse Mode - Support 5*Servo + 11*Virtual Axis

CANopen Mode - Support Max. 16 Axis

Performace:

Signal processing capability - ARM's powerful computing capability, FPGA's excellent high-speed signal

processing capability; Operation Speed - Operation cycle of 6 axis only takes 500 microseconds.

Powerful Motion Control Functions

1. Motion control function block conforms to PLCOPEN2.0,Also supports CNC function blocks

2. Support Jerk function, set the rate of change of acceleration/deceleration; Support Buffer Mode function,

softer motion curve.

3. Provide special function blocks for some industries, optimize solutions, and make the application more

convenient and efficient:

Vector focuses on providing overall solutions for customers. We have customized special modules for

customers for the industry, such as: special modules for post-press equipment, special modules for leading

edge paper feeding, cutting modules, and Absolute motion module for heavy inertia load and so on. The use

of dedicated modules makes the application of motion controllers easier and more efficient.

MULTIPROG Programming Language:

MULTIPROG supports IL, ST , FBD, LD, SFC five programming languages, of which IL and S T belong to the

text programming language, FBD, LDAnd SFC belong to the graphic programming language. A program with

independent functions is divided into code part and data part. The code is written in one or several languages

of IL, ST , FBD, LD, SFC , and the data is declared in the variable work order. This chapter describes how to

declare variables and how to program them in these five programming languages:

〖1 〗IL is an abbreviation of the Instruction List ;

〖2 〗ST is an abbreviation of Structured Text structured text;

〖3 〗FBD is an abbreviation of Function Block Diagram function chart;

〖4 〗LD is an abbreviation of Ladder Diagram ladder diagram;

〖5 〗SFC is SequentialFunction Chart is an abbreviation of sequential function chart;

In a graphics-like programming language, programs are scanned from top to bottom and left to right. In a

text-based programming language, programs are scanned from top to bottom.

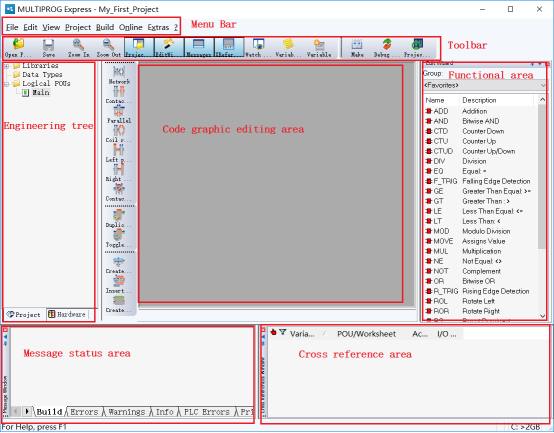

MULTIPROG programming interface presentation

After opening MULTIPROG, you caNSee that it has only one main boundary. According to the function,

it is divided into different areas, as shown.

a. Clear programming structure,standard programming language

b. Support cross-compilation between FBD, LD and IL, and support mixed programming

c. Supports IEC61131-3 programming languages: FBD, LD, IL, ST and SFC

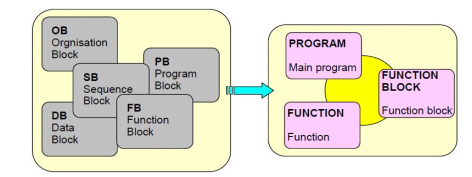

Programming model with standard IEC61131-3

1) The MULTIPROG programming software used by the VA motion controller has a programming language

and program structure in accordance with the IEC 61131-3 programming system. In IEC 61131-3, the

establishment of programs and projects is done in the Program Organization Unit (POU). The unit POU consists

of three parts: PROGRAM, FUNCTIONBLOCK and FUNCTION. It replaces the five functional blocks OB, PB, DB,

SB and FB of the traditional PLC programming language. More efficient and more concise as shown.

2) IEC 61131-3 programming software model is represented by a hierarchical structure, as shown below, the software

model describes the relationship between the various parts, including the configuration, resource, task, program

organization unit, global variables, I / O configuration, etc. . Programming process can program a complex program,

or divided into a number of small modules can also be simultaneously downloaDA plurality of separate programs, running,

or the program into a plurality of tasks to perform, improve the modularity and operational procedures efficiency as shown.

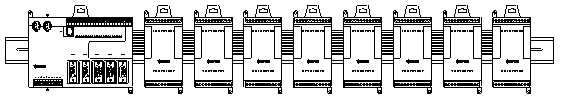

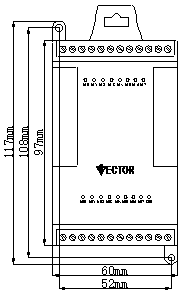

Expansion Units

The host IO expansion module of Vikeda motion controller mainly has 8IO, 16I and 16O. 8IO means that the

expansion module has 8 digital input ports and 8 digital output ports (transistor type output); 16I means that

the expansion module has 8 digital input ports and 8 digital output ports (transistor output). 16 DI ports; 16O

means that the expansion module has 16 DO ports (transistor output); among them, DI and DO can be selected

through jumpers on the motion controller host to select NPN and PNP types

The temperature of the environment where this product is used is -10°C to +40°C. For long-term work,

it is recommended that the ambient temperature be below +40°C. If the ambient temperature exceeds

+40°C, please place it in a well-ventilated place to ensure product reliability. If this product is installed in

a distribution box, the size and ventilation conditions of the distribution box must be such that all internal

electronic devices are not exposed to the danger of overheating, and attention should be paid to whether

the vibration of the machine will affect the electronic devices of the distribution box. In addition, the

conditions of use include the following:

⑴ Places without high-heating devices;

⑵ Places free of water droplets, steam, dust and oily dust;

⑶ Places where there is no corrosive, flammable gas or liquid;

⑷ Places without floating dust and metal particles;

⑸ A firm and vibration-free place;

⑹ A place without electromagnetic noise interference.

Different Expansion units and Functions

| Model | Function |

| VEC-VA-EX-8IO | 8-channel digital input, 8-channel digital output module; output type is transistor output |

| VEC-VA-EX-16I | 16 digital input module |

| VEC-VA-EX-16O | 16 digital output modules; output type is transistor output |

| VEC-VA-EX-4XA-B | 4 channels of AD input, 4 channels of DA output module; resolution is 12bit, AD input can be configured to 0~5V, 0~10V, ±10V and 0~20mA through software, DA output can be configured to 0~5V, 0~10V, ±10V |

| VEC-VA-EX-4PT-B | 4-way three-wire PT100 input module; temperature range -200~+600℃, 1mA constant current source drive, 0.1℃ measurement accuracy |

| VEC-VA-EX-4TC-B | 4-channel thermocouple input module; supports up to 8 types of thermocouples, broken couple detection, 0.1℃ measurement accuracy |

| VEC-VA-EX-2WT-B | 2-channel weighing module; multiple feature values are optional, 24bit high-resolution sampling |

Packing and Shipping

| Packing details of Motion Controller | |||||

| Products | VA Motion | VA Expansion | VE Motion | VE Expansion(32) | VE Expansion(76) |

| Ctn. Size | 176*165*78 | 127*75*70 | 144*128*69 | 176*164*78 | 316*164*78 |

Delivery Time

| Quantity | 1-5 kits | 50-100 kits | 200-500 kits |

| Delivery time | Within 3 days | 5-10 days | 15-25 days |

1. For small order we always can delivery out within 1 week.

2. Our products can be shippied via Air, Land or Sea.

CE & ROHS Certificates

Our Team