Foshan ABD Equipment Co., Ltd. |

|

Verified Suppliers

|

|

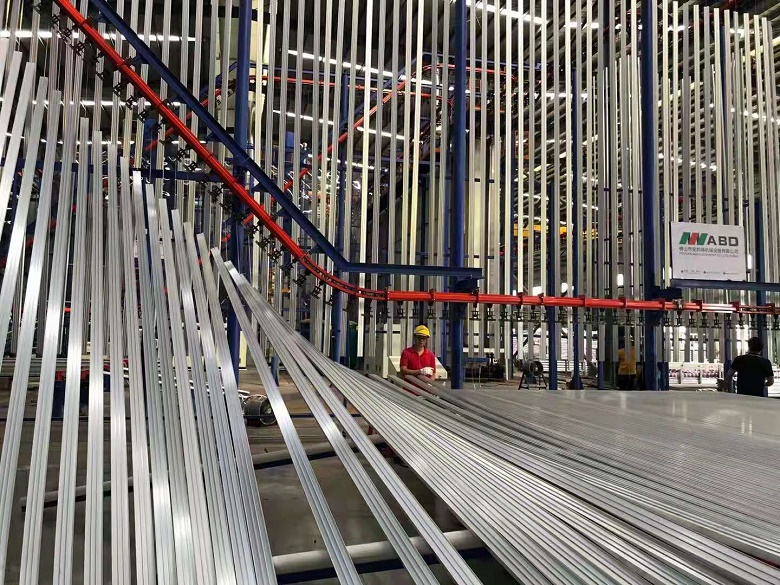

Fully Automatic Powder Coating Painting Line

This red automatic powder coating line was designed for the customer who supply the powder coating services to the others.

The working process for this line is, loading --- spray type pre-treatment --- water drying --- automatic powder coating --- automatic powder curing --- cooling --- unloading.

Automatic chain system: 2 sets driving system and 2 tensioning system. Chain can bearing 100kg/single point. Chain speed, 2.5m/min (you can adjust according your need). Total length for the chain, 295m

Pre-treatment system: Stainless steel spray type.

Steps are, pre-degreasing --- degreasing --- water washing 1 --- pure water washing 2 --- nano ceremic --- water washing 1 --- pure water washing 2

Automatic water drying oven: this oven only have the temperature for 120 Celsius.

Automatic powder coating booth: the cyclone system will help you to recycle the 99.5% of the powder, and the material is PP type, it can allow you to change the color just in 15min. And the reciprocator and automatic gun will help you to do the automatic powder coating. There will be also 2 manual working station to making up the powder coating for some dead corner.

Automatic powder curing oven: powder curing oven have the temperature for 180~230 Celsius. The work piece can curing 20~30min just according your need.

Work Piece | ||

Work piece name | Fridge, air conditioner, car parts and so on | |

Work piece max size | 2500*800*2000mm (L*W*H) | |

Front door size | 2400*2440mm (W*H) | |

Max weight per hanger | 200kg/hanger | |

Pre-treatment System | ||

Material for pre-treatment | Stainless steel SUS 304 | |

Working process: | Pre-degreasing --- degreasing --- water washing 1 --- pure water

washing 2 --- nano ceremic --- water washing 1 --- pure water washing 2 | |

Water Drying Oven | ||

Size | 30000*1550*6650mm ( L*W*H ) | |

Material | 100mm rock wool panel for the oven temperature 120 Celsius | |

Heating system | 1 set natural gas burner, 430000kcal/h, with 1 set 7.5kw high

temperature fan. | |

Powder Coating Booth | ||

Size | 7000*2000*3350mm (L*W*H) | |

Powder recycle system | One cyclone system, 1 set 30kw circulation fan, 24 pieces filter

cartridge, 2 sets of automatic reciprocators, automatic gun, manul

powder coating gun | |

Automatic Powder Oven | ||

Size | 30000*4850*6650mm (L*W*H) | |

Material | 150mm rock wool panel for the oven temperature 180~230 Celsius | |

Heating system | 2 sets natural gas burner, 600000kcal/h for each, with 1 set 15kw

high temperature fan. | |

Q1: Are you trading company or manufacturer ?

A1: We are factory and can do the exporting work by ourselves.

Q2: How long is your delivery time?

A2: About 50 workdays after received the deposit.

Q3: What is your terms of payment ?

A3: T/T and Irrevcoable L/C. 30% T/T in advance, 70% balance before shippment.

Q4: Can engineers service overseas?

A4: Yes, totally no problem.

Q5: What about the guarantee period?

A5:You will have 12 months guarantee time for the powder coating

booth, if the parts broken as our mistake, we will send you by DHL.

But as we do the pre install before the laoding, so this situation

won't very easy to happen we believe.

After one year, if you still have any help about the equipment,

please feel free to contact us at any time, as we will supply you

lifelong service.