Shenzhen 3nh Technology CO., LTD |

|

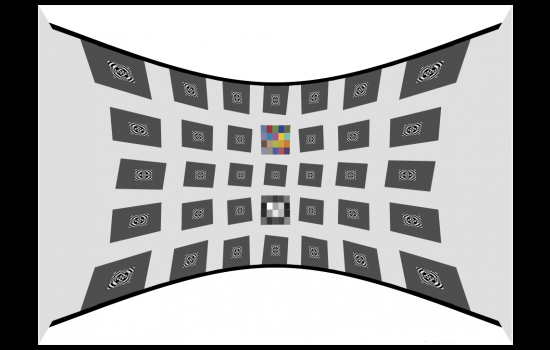

| Model | Pre-distortion Chart |

| Type | Reflective |

| Contrast Ratio | 10:1 |

| Size | 1117 mm X 1524 mm |

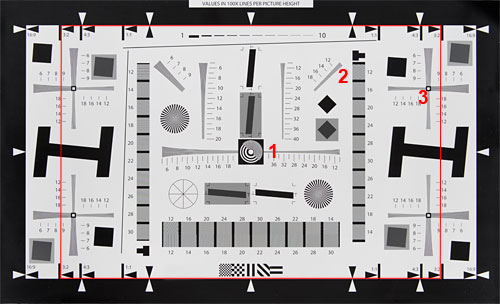

This Sineimage Pre-distortion Test Chart Automotive Test Chart is designed for testing automative cameras or other significantly distorted cameras. This large chart is designed to be reflectively lit, and captured at a an optimal focus distance.

Options include:

The active area of the chart includes white space above and below the top and bottom distortion bars. It is slightly larger than the printed area, which is bounded by the distortion bars on top and bottom. White space is included in active area because test images of the chart must include this white space in order to enable automated processing in SFRplus software.

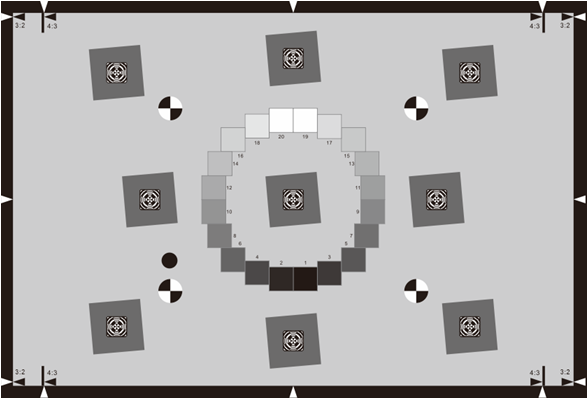

This chart, which has a 3:2 aspect ratio, is a "no-frills"

implementation of the standard. For most work we recommend the

Enhanced or Extended charts, which have additional edges for

measuring performance near the image boundaries, as well as

hyperbolic wedges and color patches (where the technology allows).

These chartsmaintain full compliance with the standard.

The Imatest Standard ISO 12233:2014 E-SFR chart closely resembles

the Low contrast E-SFR test chart illustrated in section 6.1 and

Annex C of the ISO standard document, with a few differences, all

of which are fully compliant with the ISO standard.

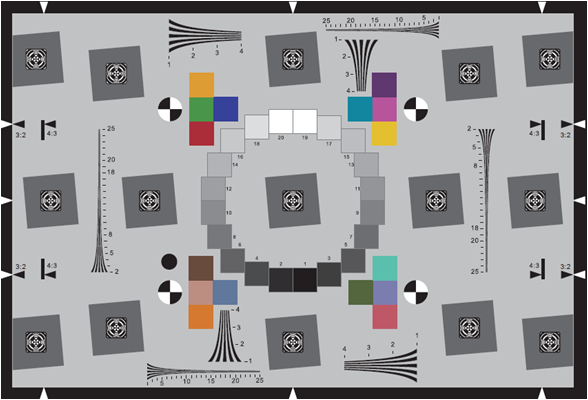

The Imatest Enhanced ISO 12233:2014 E-SFR chart has all the features of the Standard chart, keeping the 3:2 aspect ratio, with the addition of six added slanted squaresfor measuring performance near the image boundaries and hyperbolic wedges for visual analysis or analysis with the Imatest Wedge module. It also has 16 color patches when produced with technologies that allow color. Since these additions are in regions of the chart not covered by the standard, compliance with the standard is unaffected.

The differences between the Imatest charts and the chart illustrated in the standard are listed below. Even with these differences the Imatest chart is in full compliance with the standard.

The differences between the Enhanced and Standard Versions are as follows:

This chart will work with the fully-automated eSFR ISO module.

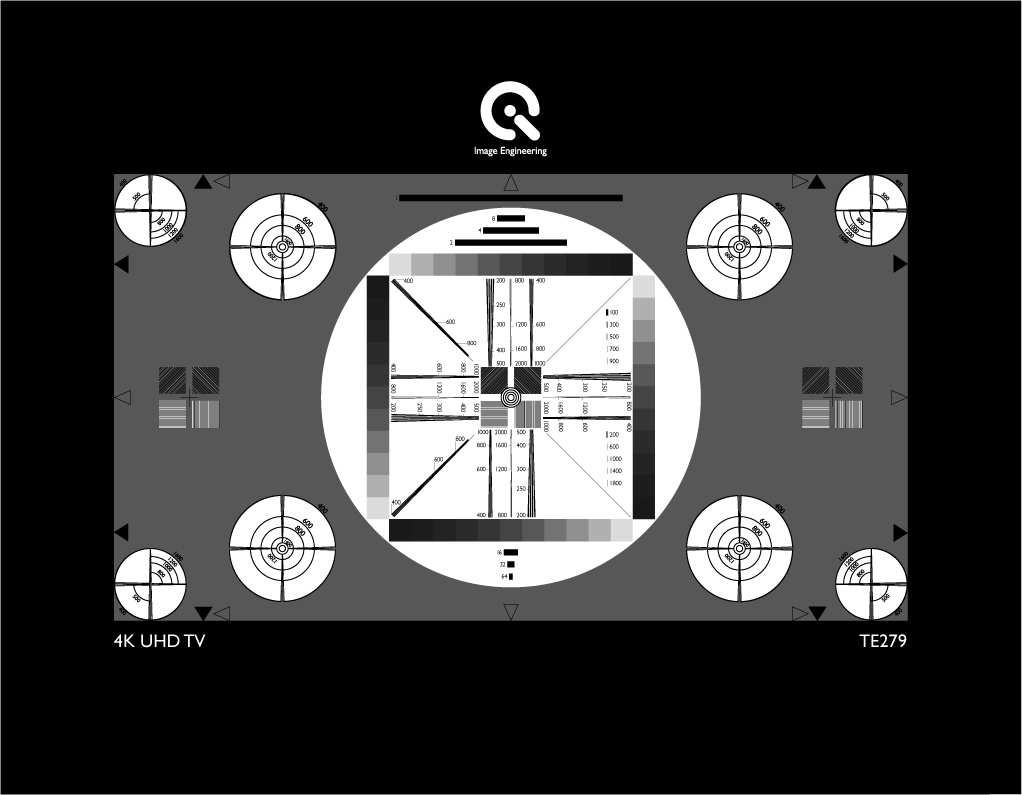

The values of the 11-graduated gray scale are as follows:

| Step | Density | Reflectance in % |

| 1 | 0.05 | 89 |

| 2 | 0.13 | 74 |

| 3 | 0.22 | 60 |

| 4 | 0.32 | 48 |

| 5 | 0.43 | 37 |

| 6 | 0.55 | 28 |

| 7 | 0.69 | 20 |

| 8 | 0.88 | 13 |

| 9 | 1.06 | 8 |

| 10 | 1.31 | 5 |

| 11 | 1.65 | 2 |

The density values are based on BaSo4 = 0. Two black fields and a white field are located between the gray scales, the density of the black filed is D > 2.4 (reflectance < 0.5 %). The density of the white filed is D = 0.05 (reflectance = 89.9 %).