Wuxi Jianbang Haoda Steel Co., Ltd |

|

Verified Suppliers

|

|

5083 Aluminum Sheet - 2mm Thickness For Fuel Tank Manufacturing

Product Description

The 5083 Aluminum Sheet with a 2mm thickness is specifically designed for fuel tank manufacturing. This high-quality aluminum sheet is ideal for fabricating fuel tanks used in various industries, including automotive, marine, and aerospace.

The 5083 alloy is known for its excellent corrosion resistance, high strength, and weldability, making it a preferred choice for fuel tank applications. The 2mm thickness provides the necessary structural integrity while maintaining a lightweight design, optimizing fuel efficiency and overall performance.

This aluminum sheet is carefully manufactured to meet stringent industry standards, ensuring consistent quality and dimensional accuracy. It can be easily cut, formed, and welded to create precise fuel tank components with tight tolerances and reliable performance.

The 5083 Aluminum Sheet offers exceptional resistance to corrosive environments, ensuring the longevity and durability of the fuel tank. It withstands exposure to various fuels, including gasoline, diesel, and aviation fuel, without degradation or compromise.

With its precise dimensions and high-quality construction, the 5083 Aluminum Sheet with a 2mm thickness provides reliable performance and efficient fuel tank manufacturing. Its corrosion resistance, strength, and lightweight properties contribute to the safety, reliability, and fuel efficiency of the tanks.

In summary, the 5083 Aluminum Sheet with a 2mm thickness is an excellent choice for fuel tank manufacturing. Its corrosion resistance, strength, and weldability make it suitable for demanding applications. Whether used in automotive, marine, or aerospace industries, this aluminum sheet ensures the production of durable, lightweight, and reliable fuel tanks.

Here are some additional details about the 5083 Aluminum Sheet with a 2mm thickness for fuel tank manufacturing:

Alloy Composition: The 5083 Aluminum alloy is primarily composed of aluminum, with small amounts of magnesium, manganese, and chromium. This alloy composition provides excellent corrosion resistance, high strength, and good formability, making it well-suited for fuel tank applications.

2mm Thickness: The 2mm thickness of the aluminum sheet is specifically chosen for fuel tank manufacturing. This thickness strikes a balance between structural integrity and weight savings, ensuring the fuel tank is strong enough to withstand external forces while keeping it lightweight for improved fuel efficiency.

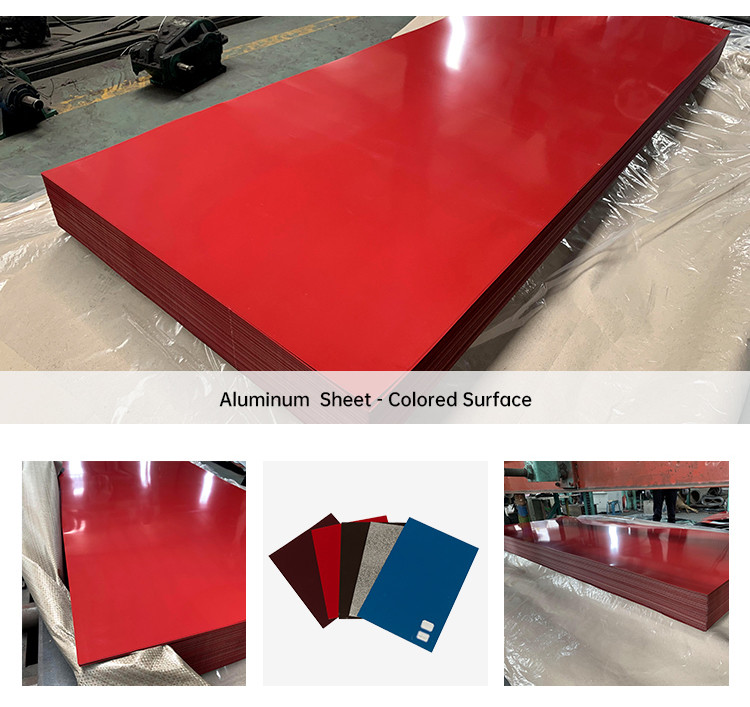

Surface Finish: The 5083 Aluminum Sheet typically has a smooth and clean surface finish. This surface finish is important for ensuring proper adhesion of coatings or paints applied to the sheet during the fuel tank manufacturing process. It also facilitates the seamless integration of the sheet into the overall tank structure.

Weldability: The 5083 Aluminum alloy is known for its excellent weldability. It can be easily welded using various methods such as MIG, TIG, or resistance welding. This enables the fabrication of complex fuel tank designs and ensures strong and reliable joints, minimizing the risk of fuel leakage.

Corrosion Resistance: The 5083 Aluminum Sheet offers exceptional corrosion resistance, particularly in marine environments or when exposed to fuels and chemicals. This corrosion resistance ensures the longevity and integrity of the fuel tank, reducing the risk of leaks and maintaining the fuel quality.

Formability: The 5083 Aluminum Sheet demonstrates good formability, allowing it to be easily shaped and formed into the desired fuel tank components. This facilitates the production of custom fuel tank designs that meet specific application requirements.

Quality Assurance: The 5083 Aluminum Sheet for fuel tank manufacturing undergoes thorough quality checks to ensure it meets the required specifications. These checks include dimensional measurements, surface inspections, and mechanical property testing. Quality assurance measures help ensure consistent performance and reliability of the fuel tanks produced.

Industry Compliance: The 5083 Aluminum Sheet complies with relevant industry standards and specifications for fuel tank manufacturing. It meets the necessary requirements for strength, corrosion resistance, and weldability, ensuring its suitability for use in various industries, including automotive, marine, and aerospace.

In summary, the 5083 Aluminum Sheet with a 2mm thickness is a high-quality material specifically designed for fuel tank manufacturing. Its alloy composition, 2mm thickness, surface finish, weldability, corrosion resistance, formability, and adherence to industry standards make it an excellent choice for manufacturers in the fuel tank industry. The 5083 Aluminum Sheet provides the necessary properties to produce fuel tanks that are durable, lightweight, resistant to corrosion, and compliant with industry requirements.

Here are some additional details about the 5083 Aluminum Sheet with a 2mm thickness for fuel tank manufacturing:

Heat Treatment: The 5083 Aluminum alloy can be heat treated to enhance its mechanical properties. The heat treatment process involves heating the sheet to a specific temperature and then rapidly cooling it to achieve desired hardness and strength. Heat treatment further improves the sheet's resistance to deformation and enhances its overall performance in fuel tank applications.

Structural Integrity: The 5083 Aluminum Sheet with a 2mm thickness offers excellent structural integrity for fuel tanks. Its high strength-to-weight ratio allows for the construction of fuel tanks that are both lightweight and robust. This is particularly important for applications where weight reduction is a priority, such as in the automotive and aerospace industries.

Machinability: The 5083 Aluminum Sheet exhibits good machinability, meaning it can be easily machined or shaped using conventional machining processes such as milling, drilling, and turning. This enables manufacturers to fabricate fuel tank components with intricate geometries and precise dimensions, ensuring a proper fit and optimal performance.

Compatibility with Joining Methods: The 5083 Aluminum alloy is compatible with various joining methods, including riveting, bonding, and adhesive bonding. This allows for the assembly of fuel tanks using different joining techniques, providing flexibility in design and construction.

Non-Magnetic Properties: The 5083 Aluminum Sheet is non-magnetic, making it suitable for fuel tank applications where magnetic interference must be minimized. This property ensures that the fuel tank does not interfere with sensitive electronic components or magnetic field-sensitive equipment.

Resistance to Extreme Temperatures: The 5083 Aluminum alloy exhibits excellent performance in extreme temperature environments. It retains its mechanical properties and corrosion resistance even at low temperatures, making it suitable for fuel tanks that may experience temperature variations during operation.

Compliance with Safety Standards: The 5083 Aluminum Sheet meets stringent safety standards and regulations for fuel tank manufacturing, ensuring that it fulfills the necessary requirements for strength, durability, and corrosion resistance. Compliance with safety standards is crucial to ensure the safe storage and transportation of fuels.

Longevity and Low Maintenance: The 5083 Aluminum Sheet offers excellent longevity and requires minimal maintenance in fuel tank applications. Its corrosion resistance and durability help extend the service life of the fuel tank, reducing maintenance costs and downtime.

In summary, the 5083 Aluminum Sheet with a 2mm thickness is a high-quality material specifically designed for fuel tank manufacturing. Its heat treatability, structural integrity, machinability, compatibility with joining methods, non-magnetic properties, resistance to extreme temperatures, compliance with safety standards, longevity, and low maintenance make it an excellent choice for fuel tank manufacturers. The 5083 Aluminum Sheet provides the necessary properties to produce fuel tanks that are lightweight, strong, corrosion-resistant, and compliant with industry regulations.