Wuxi Jianbang Haoda Steel Co., Ltd |

|

Verified Suppliers

|

|

7075 Aluminum Sheet - 4mm Thickness For Vertical Tail Components

Description:

The 7075 Aluminum Sheet with a 4mm thickness is specifically designed for use in vertical tail components. This high-strength aluminum alloy sheet offers exceptional performance and durability, making it an ideal choice for critical aerospace applications.

Vertical tail components play a crucial role in aircraft stability and control. They are responsible for providing directional stability and maneuverability during flight. The 7075 Aluminum Sheet is well-suited for these components due to its superior strength-to-weight ratio and excellent fatigue resistance.

Manufactured using advanced processes, the 7075 Aluminum Sheet exhibits exceptional mechanical properties, including high tensile strength and toughness. This enables it to withstand the aerodynamic forces and structural loads experienced by vertical tail components during flight operations.

In addition to its strength, the 7075 Aluminum Sheet offers excellent corrosion resistance. This is particularly important for aerospace applications, as aircraft are exposed to various environmental conditions, including moisture and harsh chemicals. The corrosion resistance of the 7075 alloy helps maintain the structural integrity and performance of the vertical tail components over their operational lifespan.

The 4mm thickness of the aluminum sheet provides the necessary structural integrity and stiffness required for vertical tail components. It offers sufficient strength to withstand the aerodynamic forces and vibrations encountered in flight, ensuring the reliability and safety of the aircraft.

Furthermore, the 7075 Aluminum Sheet can be easily fabricated and machined to meet the specific design requirements of vertical tail components. It can be formed, cut, and welded with relative ease, allowing for precise manufacturing and assembly processes.

In summary, the 7075 Aluminum Sheet with a 4mm thickness is a high-performance material for vertical tail components in aerospace applications. Its exceptional strength, fatigue resistance, corrosion resistance, and ease of fabrication make it an ideal choice for ensuring the stability, control, and safety of aircraft during flight operations.

Here are some additional details about the 7075 Aluminum Sheet with a 4mm thickness for vertical tail components:

High Strength-to-Weight Ratio: The 7075 Aluminum Sheet is known for its high strength-to-weight ratio. This means that it provides exceptional strength and structural integrity while being relatively lightweight. This is crucial for vertical tail components as it helps reduce the overall weight of the aircraft, contributing to improved fuel efficiency and performance.

Excellent Fatigue Resistance: Vertical tail components, such as the vertical stabilizer and rudder, are subjected to cyclic loads and vibrations during flight. The 7075 Aluminum Sheet exhibits excellent fatigue resistance, allowing it to withstand these repeated load cycles without compromising its structural integrity. This ensures the long-term reliability and durability of the vertical tail components.

Aerospace-Grade Quality: The 7075 Aluminum Sheet is specifically designed to meet the stringent requirements of the aerospace industry. It may comply with various industry standards and certifications, ensuring that it meets the necessary quality and performance standards for aerospace applications. This includes adherence to specific dimensional tolerances, material properties, and manufacturing processes.

Machinability and Formability: The 7075 Aluminum Sheet offers good machinability and formability characteristics. This means that it can be easily machined, shaped, and formed into complex geometries required for vertical tail components. It can be cut, drilled, bent, and fabricated with relative ease, allowing for efficient manufacturing and assembly processes.

Corrosion Resistance: The 7075 Aluminum Sheet exhibits good corrosion resistance, particularly in comparison to other aluminum alloys. This is essential for vertical tail components as they are exposed to various environmental conditions, including moisture, temperature variations, and chemicals. The corrosion resistance of the 7075 alloy helps protect the vertical tail components from degradation and ensures their long-term performance and reliability.

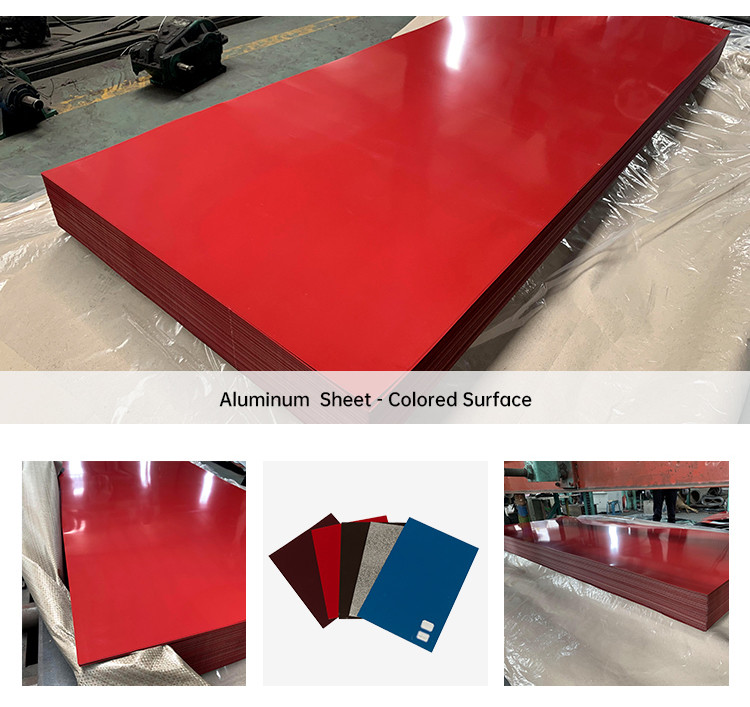

Surface Treatment Options: The surface of the 7075 Aluminum Sheet can be treated with various coatings or finishes to enhance its performance and appearance. Common surface treatments include anodizing, which provides a protective oxide layer to further improve corrosion resistance, and painting, which allows for customized aesthetics and added protection.

In summary, the 7075 Aluminum Sheet with a 4mm thickness is a high-performance material specifically designed for vertical tail components in aerospace applications. Its high strength-to-weight ratio, excellent fatigue resistance, aerospace-grade quality, machinability, formability, corrosion resistance, and surface treatment options make it an ideal choice for ensuring the strength, durability, and functionality of vertical tail components in aircraft.

Here are some additional details about the 7075 Aluminum Sheet with a 4mm thickness for vertical tail components:

Heat Treatable: The 7075 Aluminum Sheet is heat treatable, which means it can be subjected to controlled heat treatment processes to further enhance its mechanical properties. Heat treatment can increase the strength and hardness of the material, making it even more suitable for demanding applications such as vertical tail components.

Weldability: The 7075 Aluminum Sheet exhibits good weldability, allowing for the fabrication of complex structures and assemblies. It can be joined using various welding techniques, including TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding, to create strong and reliable connections between components.

High-Corrosion Resistance: The 7075 Aluminum Sheet offers high resistance to corrosion, particularly in harsh environments. This is attributed to the alloy's composition, which includes elements such as zinc and magnesium. The corrosion resistance of the 7075 alloy ensures that the vertical tail components remain protected and maintain their performance even when exposed to moisture, saltwater, and other corrosive substances.

Precision Machining: The 7075 Aluminum Sheet is known for its excellent machinability. It can be easily machined to achieve tight tolerances and precise dimensions required for vertical tail components. This allows for the production of intricate parts with intricate designs and complex geometries.

Non-Magnetic: Another advantage of the 7075 Aluminum Sheet is its non-magnetic property. This makes it suitable for applications where magnetic interference needs to be minimized, such as in aircraft and aerospace systems.

Aerospace Standards and Certifications: The 7075 Aluminum Sheet may comply with various aerospace standards and certifications, including those set by organizations such as the International Aerospace Quality Group (IAQG) and the National Aerospace and Defense Contractors Accreditation Program (NADCAP). These standards ensure that the material meets the necessary quality, performance, and safety requirements for use in aerospace applications.

In summary, the 7075 Aluminum Sheet with a 4mm thickness offers a range of advantages for vertical tail components. Its heat treatability, weldability, high corrosion resistance, precision machining capabilities, non-magnetic properties, and compliance with aerospace standards make it a reliable and versatile material choice for vertical tail components in aerospace applications.